K-WANG

GE Digital Energy Hydran 201Ti Transformer DGA Monitor

It provides the basic information used by IEEE® Standard C57.104 and can be used as an essential first line of defence for the transformers in your fleet to obtain advance warning of a failure condition and minimize the risk of unplanned outages.

GE Digital Energy Hydran 201Ti Transformer DGA Monitor

Hydran 201Ti is a small, easy to install continuous dissolved gas analysis (DGA) monitor for transformer oil launched by GE Digital Energy, based on IEEE ® Standard C57.104 provides core monitoring data, which can serve as the primary line of defense for transformer fault warning and reduce the risk of unplanned downtime. Its latest Mark IV version has been optimized in design and functionality, and currently has sales of over 30000 units and a huge installed base.

Core functions and technical features

1. Gas monitoring capability

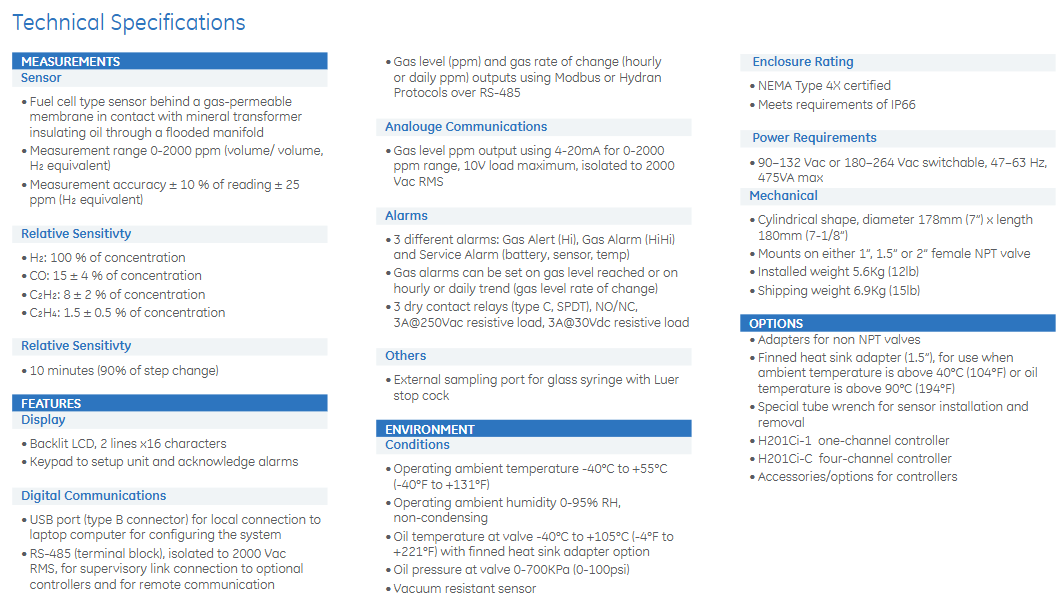

Sensor technology: using fuel cell type sensors with breathable membranes, in contact with mineral transformer insulation oil through "dynamic oil sampling" technology, without the need for pumps or additional pipelines; Optional 5-year sensor warranty.

Monitoring range and accuracy: The H ₂ equivalent measurement range is 0-2000ppm (volume ratio), with an accuracy of ± 10% ± 25ppm of the reading; Fast response speed, 90% step change only takes 10 minutes.

Gas sensitivity: 100% response to H ₂ (universal fault gas), while sensitive to CO (paper overheating), C ₂ H ₂ (arc discharge), and C ₂ H ₄ (oil overheating), covering all major fault sources of transformers.

2. Display and operation

Equipped with a backlit LCD display screen (2 lines x 16 characters), it can display the dissolved gas ppm value in real time.

Comes with a built-in keyboard that supports device settings and alarm confirmation operations.

3. Communication function

Local communication: Equipped with a USB B-type interface, it replaces the RS-232 interface that has been removed from most on-site laptops, making it convenient to connect to a computer and configure the system locally.

Remote communication:

Analog output: 4-20mA signal (corresponding to 0-2000ppm range), maximum load 10V, insulation level 2000Vac RMS.

Digital output: Through an isolated RS-485 interface, supporting Modbus or Hydran protocols, outputting gas ppm values and hourly/daily gas change rate (ROC).

Dry contact relay: 3 SPDT type relays (C type), 2 for fault gas alarm, 1 for service alarm, rated load: 3A@250Vac or 3A@30Vdc .

4. Alarm and self check

Configurable alarms: Supports two-level gas alarms (Alert warning, Alarm emergency), which can be set based on gas ppm concentration or hourly/daily change rate; Triggering an alarm when abnormal fault gas levels are detected.

Automatic self check: Conduct a self check every 15 days. If power failure, oil valve closure, sensor or battery replacement issues are found, a service alarm will be triggered.

Installation and compatibility

1. Installation characteristics

Single valve installation design, directly installed on the transformer oil valve without the need for additional pipelines or pumps; Compatible with 1-inch, 1.5-inch, and 2-inch internal thread NPT valves.

The shape is cylindrical, with a diameter of 178mm (7 inches) and a length of 180mm (7 and 1/8 inches); Installation weight 5.6Kg (12 pounds), transportation weight 6.9Kg (15 pounds).

Optional accessories: Non NPT valve adapter, fin heat dissipation adapter (used when the ambient temperature exceeds 40 ° C or the oil temperature exceeds 90 ° C), sensor installation/removal special pipe wrench.

2. Controller and Networking

Can connect optional controllers to build a local network, supports RS-485 "daisy chain" connection, can connect up to 32 controllers or 201Ti devices in series, with a total chain length of up to 1200m (4000 feet), and all devices can be accessed through any controller in the network.

Two types of core controllers:

Ci-1 single channel controller: replicates some human-machine interaction functions (gas value display, alarm button), suitable for use when installing 201Ti in high position valves of transformers. It also leads out alarm relay contacts and analog outputs for easy wiring.

Ci-C four channel controller: capable of receiving gas ppm data from 4 201Ti units, providing a single communication point, no alarm relay, and analog output, suitable for protecting 3 single-phase transformers and 1 backup transformer scenarios.

3. Software compatibility

Compatible with GE's well-known Perception Fleet software, supporting data download, trend analysis, and management, and operating logic consistent with other GE DGA monitoring devices.

Environmental and power requirements

1. Environmental adaptability

Working environment temperature: -40 ° C to+55 ° C (-40 ° F to+131 ° F).

Working environment humidity: 0-95% RH (non condensing).

Oil temperature at the valve: -40 ° C to+105 ° C (-4 ° F to+221 ° F, requires fin heat dissipation adapter).

Oil pressure at the valve: 0-700KPa (0-100psi), the sensor has anti vacuum capability.

Protection level: NEMA 4X certified, meets IP66 requirements.

2. Power parameters

AC power supply: switchable between 90-132Vac or 180-264Vac, frequency 47-63Hz, maximum power consumption 475VA.

Applicable scenarios

1. Power Utilities

Provide a simple and effective monitoring solution for non critical transformers.

Focus and prioritize the replacement strategy of auxiliary assets to optimize asset management.

2. Industrial Plants

Reduce the risk of production process interruption caused by power failures.

Reduce high production downtime losses and ensure continuous production.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923