K-WANG

Bently Nevada 3300 XL High Temperature Proximity Detection System (HTPS)

Combining the dual value of "online monitoring and protection" and "research and development/troubleshooting": it is used for real-time protection of key equipment in industrial sites, and also supports turbine mode shape analysis, helping new machine research and development and old machine fault diagnosis (such as shaft cracks, bearing failures, dynamic and static friction, etc.).

Bently Nevada 3300 XL High Temperature Proximity Detection System (HTPS)

System core positioning and application scenarios

1. Core positioning

Addressing the pain point of traditional proximity probes being easily damaged in high-temperature environments, it can operate stably in continuous high temperatures up to+350 ° C (+662 ° F) and is used to measure key parameters such as vibration, thrust position, and differential expansion. It is compatible with Bently Nevada's entire range of monitoring and diagnostic equipment.

Combining the dual value of "online monitoring and protection" and "research and development/troubleshooting": it is used for real-time protection of key equipment in industrial sites, and also supports turbine mode shape analysis, helping new machine research and development and old machine fault diagnosis (such as shaft cracks, bearing failures, dynamic and static friction, etc.).

2. Typical application scenarios

Focusing on the high-temperature areas of gas turbines and steam turbines, including:

Near the labyrinth seal of the steam turbine, differential expansion measurement points;

Gas turbine bearing seat support pillar, probe for threading in exhaust path;

Monitoring of faulty bearings in high-temperature areas;

Modal analysis and online diagnosis of turbine mid span position;

Measurement of inter stage radial/axial sealing clearance at the mid span position of a multi-stage steam turbine to reduce sealing friction.

Core advantages and design features of the system

1. Extreme environmental adaptability

High temperature tolerance: The probe integrates a hard wired cable, with a rated continuous working temperature of+350 ° C (+662 ° F), far exceeding traditional probes;

Durable structure: Ceramic probe tip (sealed, moisture-proof, and anti pollution)+AISI 316L stainless steel shell (corrosion-resistant), can withstand 100% condensation humidity, and the probe connector can be submerged after protection;

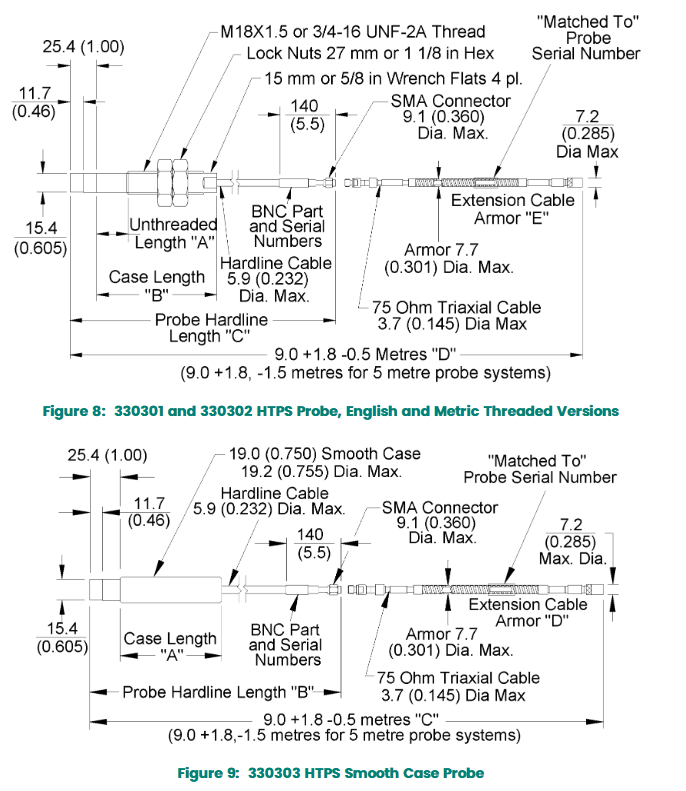

Flexible installation: Available in two styles: threaded housing (3/4-16 UNF, M18 × 1.5) and smooth housing. The smooth housing is paired with a clamping mounting bracket to solve the problem of difficult calibration in traditional threaded installation of long cable probes (2m/5m).

2. Performance and compatibility

Measurement accuracy: Linear range of 4.0mm (160 mil, 0.5-4.5mm interval), incremental scaling factor (ISF) of 3.94 V/mm (100 mV/mil), best fit line deviation (DSL) of ≤± 78 μ m (± 3.1 mil), ISF deviation at high temperature (22-350 ° C) of ≤± 30%;

Fully compatible design: The signal output (3.94 V/mm) is compatible with all new and old Bently Nevada monitoring devices, supports field wiring up to 305 meters (1000 feet), and has a frequency response of 0-6kHz (± 0, -3dB).

Core technical specifications

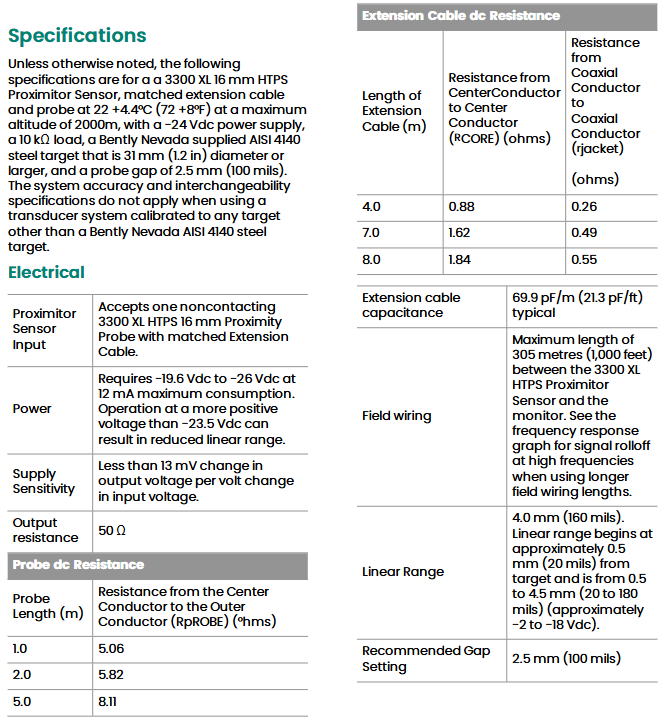

1. Electrical specifications (default test conditions: 22 ± 4.4 ° C, 2000m altitude, -24Vdc power supply, AISI 4140 steel target)

Category key parameters

Power supply requirements input voltage -19.6~-26Vdc, maximum power consumption 12mA; voltage higher than -23.5Vdc will shorten the linear range

Output characteristics: Output resistance 50 Ω, power supply sensitivity ≤ 13mV/V (output change ≤ 13mV for every 1V change in input voltage)

Probe resistance 1m Probe: 5.06 Ω; 2m probe: 5.82 Ω; 5m probe: 8.11 Ω (center conductor outer conductor)

Extended cable capacitance 69.9pF/m; 4m cable resistance: core wire 0.88 Ω, coaxial conductor 0.26 Ω; 7m cable: core wire 1.62 Ω, coaxial conductor 0.49 Ω

2. Mechanical and environmental specifications

Category key parameters

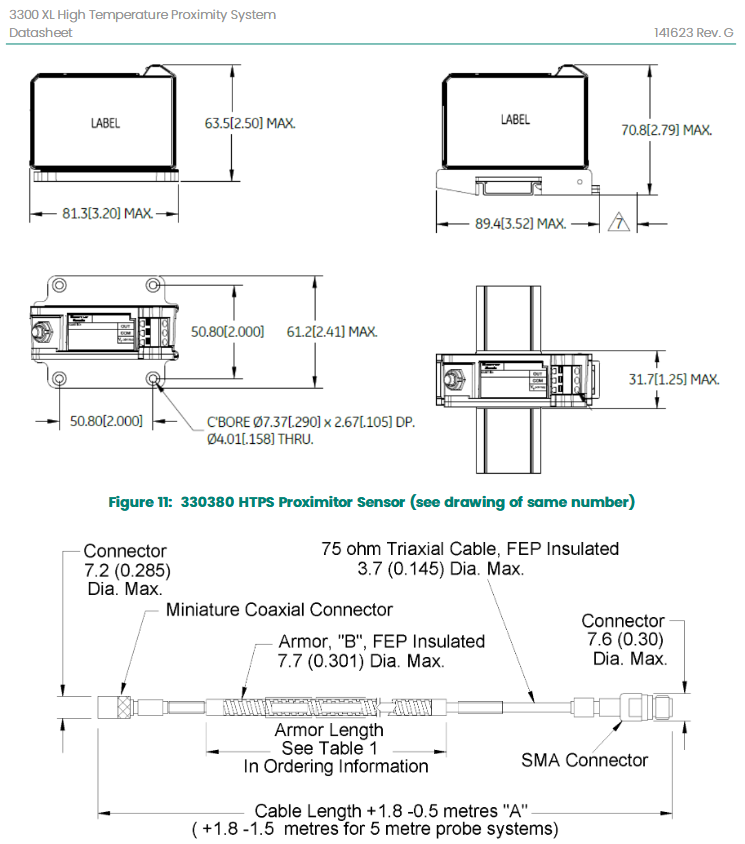

Material probe housing: AISI 316L stainless steel; Hardwire cable: AISI 304L stainless steel; Extension cable: FEP insulated 75 Ω triaxial cable; Sensor housing: epoxy powder coated aluminum

The total length of the size and weight system is 9m (including extension cables); Probe weight 117g/m (cable)+12g/cm (casing); Sensor weight 255g (9oz)

Maximum tensile strength of 289N (65 pounds, probe extension cable); The maximum torque of the probe housing is 81N · m (720 in. lb); Minimum bending radius 25.4mm (1in)

Temperature range probe: -34~+350 ° C (storage/operation); Extension cable: -52~+177 ° C; sensor: working -52~+100 ° C, storage -52~+105 ° C

Hardware composition and model classification

The system core consists of "probe+extension cable+Proximitor Sensor", and each component model is subdivided by function, supporting customized selection:

1. Core probe model (Class 3)

Example of Key Parameters for Model Series Type Selection

330301 3/4-16 UNF threaded housing A (unthreaded length, 0.0-5.4in, 0.1in increments), B (total housing length, 1.1-6.5in, 0.1in increments), C (hard wire length: 10=1m/20=2m/50=5m), D (total length: 90=9m), E (armor: 00 none/01 present), F (certification: 00 not required) 330301-012-060-10-90-00-00 (unthreaded 1.2in, housing 6.0in, hard wire 1m, total length 9m, no armor, no certification)

330302 M18 × 1.5 threaded shell A (unthreaded length, 0-130mm, 10mm increments), B (total shell length, 30-160mm, 10mm increments), C/D/E/F are the same as 330301 330302-050-130-20-90-01-00 (unthreaded 50mm, shell 130mm, hard wire 2m, total length 9m, armored but not certified)

330303 Smooth Shell (with mounting bracket) A (total shell length, 0.6-9.9in, 0.1in increments), B (hard wire length), C (total length), D (armor), E (certified) 330303-060-10-90-00-00 (shell 6.0in, hard wire 1m, total length 9m, no armor, no certification)

2. Sensor model (330380 series)

Replace the old model 330300, with a core distinction of "installation method" and parameters:

Selection parameter A (total length+installation): 90=9m panel installation, 91=9m DIN installation, 92=9m without installation hardware;

Selection parameter B (certification): 00=no certification required.

3. Accessories and extension cables

Backup extension cable (330330): It needs to match the original probe serial number, with a length of 4m (040)/7m (070)/8m (080), supporting armor (01 with/00 without);

On site wiring cable (132501): 18AWG (1.0mm ²) 3-core shielded wire, length 2-99 feet (0.6-30m), with wire lugs at both ends;

Documents and Bracket: 125M6030 (User Guide), 159132 (Performance Specifications), 134835-01 (330303 Probe Backup Installation Bracket).

Compliance and Precautions

1. Compliance certification

Electromagnetic compatibility: compliant with EU CE certification;

Environmental Protection: Compliant with RoHS Directive 2011/65/EU;

Wireless interference: Complies with FCC Part 15 regulations (does not generate harmful interference, and is tolerant of interference).

2. Key precautions

Target material requirements: System accuracy based on Bently Nevada AISI 4140 steel target (diameter ≥ 31mm), using other target materials may affect accuracy;

Small shaft diameter measurement: When the shaft diameter is less than 76mm (3in), attention should be paid to the electromagnetic interference of the probe (radial vibration probe spacing ≥ 54mm, axial position ≥ 64mm). When the shaft diameter is less than 152mm (6in), it will cause changes in the proportional coefficient, and reference should be made to specification 159132;

Pressure and Leakage: The probe is designed to seal the pressure difference between the tip and the housing, but pressure testing is not conducted at the factory; High/low pH solutions may corrode the probe tip and cause leakage. Bently Nevada is not responsible for any leakage damage, and the leaking probe is not covered by the service plan warranty.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923