K-WANG

Bently 330400 and 330425 acceleration sensors

330400: Range of 50 g peak, sensitivity of 100 mV/g, suitable for monitoring moderate vibration intensity.

330425: Larger range (75 g peak), sensitivity of 25 mV/g, suitable for high vibration intensity scenarios.

Bently 330400 and 330425 acceleration sensors

Product Overview

1. Core purpose and design objectives

The 330400 and 330425 acceleration sensors are designed specifically for measuring the acceleration of critical machinery casings, especially suitable for scenarios such as gear meshing monitoring. Both comply with the American Petroleum Institute API 670 standard, with the main differences being range and sensitivity:

330400: Range of 50 g peak, sensitivity of 100 mV/g, suitable for monitoring moderate vibration intensity.

330425: Larger range (75 g peak), sensitivity of 25 mV/g, suitable for high vibration intensity scenarios.

2. Application precautions

The sensor needs to be installed on the bearing seat or casing to ensure that the rotor vibration can be effectively transmitted to the installation position, otherwise it may cause measurement signal attenuation or distortion.

Improper installation can affect amplitude and frequency response. It is recommended to refer to the accompanying manual and application guide, and if necessary, apply for Bently Nevada's engineering services to determine the best installation solution.

Detailed explanation of technical specifications

Electrical performance parameters

Parameters: 330400 detailed specifications/330425 detailed specifications

Sensitivity: 10.2 mV/m/s ² (100 mV/g), with an error of ± 5%, calibrated at 20-30 ° C and 100Hz/2.5 mV/m/s ² (25 mV/g), with an error of ± 5%, under the same calibration conditions

Acceleration range: 490 m/s ² (50 g) peak, only valid within the frequency range of 10 Hz-15 kHz; A frequency above 15 kHz (especially the resonance point) will significantly reduce the range/735 m/s ² (75 g) peak, and the range limit is consistent with 330400

Amplitude linearity: ± 1% (when acceleration ≤ 490 m/s ² peak)/± 1% (when acceleration ≤ 735 m/s ² peak)

Broadband noise base: 0.039 m/s ² (0.004 g) rms, frequency range 10 Hz-15 kHz/unspecified, performance consistent with 330400 within the same frequency band

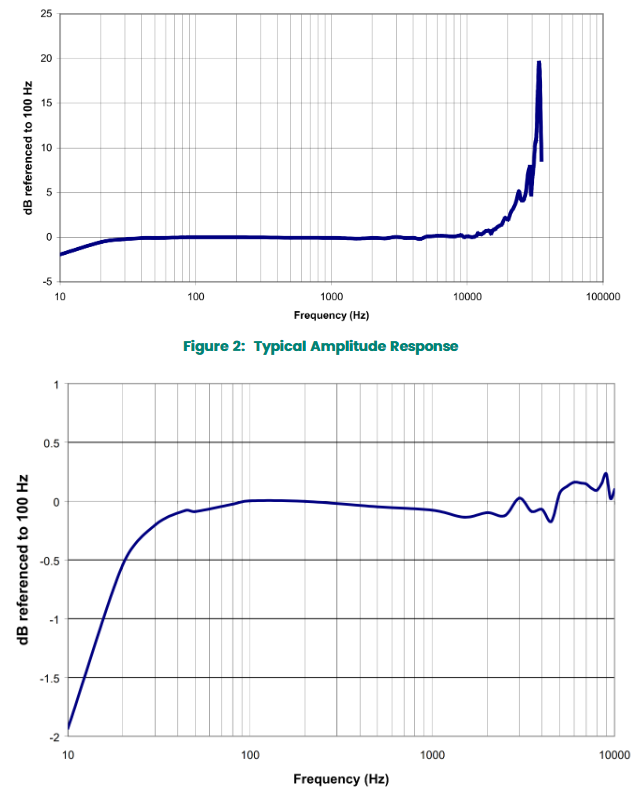

Frequency response: -10 Hz-15 kHz: ± 3 dB/-30 Hz-10 kHz: ± 10%

(Ensure accurate capture of vibration signals within a wide frequency range)/Completely consistent with 330400

Temperature sensitivity: typical value -11% to+3% (the rate of change of sensitivity with temperature within the operating temperature range)/completely consistent with 330400

Lateral sensitivity:<5% (relative to axial sensitivity, reducing the impact of installation angle errors on measurement)/completely consistent with 330400

Installation resonance frequency:>30 kHz (to avoid interference from resonance on high-frequency vibration measurement)/completely consistent with 330400

Power requirements: - Input voltage: -24 ± 0.5 Vdc

-Bias current: 2 mA (nominal)/exactly consistent with 330400

Output bias voltage: -8.5 ± 0.5 Vdc (reference voltage relative to ground)/completely consistent with 330400

Grounding design: shell isolation (to avoid interference with measurement signals caused by grounding loops)/completely consistent with 330400

Maximum cable length: 305 meters (1000 feet), with no signal attenuation when using the specified cable, identical to 330400.

Environmental adaptability parameters

1、 Temperature range

Working and storage temperature

Range: -55 ° C to+121 ° C (-67 ° F to+250 ° F)

Explanation: The sensor can work stably in extreme high and low temperature environments, suitable for high temperature equipment such as industrial furnaces and steam turbines, or cold outdoor scenes. It can also withstand this temperature range during storage without the need for additional temperature control protection.

2、 Impact bearing capacity

Impact limit

Peak value: 49050 m/s ² (5000 g)

Description: It can withstand severe mechanical impacts (such as accidental collisions during installation, instantaneous impacts during equipment start-up/shutdown), ensure that internal components are not damaged, and is suitable for heavy industrial environments with severe vibrations (such as mining machinery and stamping equipment).

3、 Humidity and protective performance

relative humidity

Tolerance range: 100% condensation (non submerged state)

Protection design: The sensor housing is sealed tightly and made of 316L stainless steel material, which can prevent water vapor and dust from entering the internal circuit. It is suitable for humid workshops, outdoor rainy and snowy environments, or high humidity process flows (such as papermaking and food processing).

IP rating

Equivalent protection: IP68 (dustproof and waterproof)

Note: This level is only applicable to the sensor body, and the cable part needs to be separately protected to avoid water ingress or wear.

4、 Magnetic field anti-interference ability

Magnetic field sensitivity

Limit value:<2.21 mm/s ²/Gauss (225 mg/Gauss), test conditions are 50 Gauss, 50-60Hz magnetic field

Explanation: In strong electromagnetic environments (such as near motors and transformers), it is less affected by magnetic field interference, ensuring the accuracy of vibration measurement data and reducing false signals.

5、 Base strain sensitivity

Regarding the differences in different serial numbers

The serial number starts with "G" (produced after April 2004): 49 mm/s ²/mstrain (0.005 g/mtrain), and the influence of substrate strain on measurement is minimal, so there is no need to install an additional base.

Serial number without "G" (produced before April 2004):

When there is no installation base: 980 mm/s ²/mstrain (0.100 g/mtrain), with high strain sensitivity, it needs to be used in conjunction with a dedicated installation base.

When equipped with a mounting base: 4.9 mm/s ²/mstrain (0.0005 g/mtrain), it can effectively reduce substrate strain interference.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923