K-WANG

Woodward PGPL electro-hydraulic actuator/driver(37519 G version)

Alternative value: Used to replace traditional hydraulic mechanical governors such as PG-PL, PGD, PGL, etc., retaining the convenience of the original PG type transmission and connecting rod system, while possessing high precision and flexibility of electronic control.

Woodward PGPL electro-hydraulic actuator/driver

Product core positioning and application scenarios

1. Core positioning

Technology type: Electro hydraulic integrated actuator, including proportional drive interface, capable of receiving electronic controllers (such as Woodward 2301A series, 700 series, etc.) Peak ® The 0-200mA position signal output by the 150 and 505 controllers is controlled by a torque motor and a follow-up pilot valve to drive the output shaft, and coupled with a contactless position sensor to achieve closed-loop control.

Alternative value: Used to replace traditional hydraulic mechanical governors such as PG-PL, PGD, PGL, etc., retaining the convenience of the original PG type transmission and connecting rod system, while possessing high precision and flexibility of electronic control.

2. Scope of application

Adaptation equipment: gas engines, steam turbines (such as power generation turbines, industrial compressor driven turbines);

Hazardous Area Compliance: Compliant with UL certification, suitable for Class I Zone 2, A/B/C/D hazardous environments (models with magnetic electric sensor (MPU) options do not have UL/cUL certification);

Linkage system: It needs to be used in conjunction with an electronic governor, and its core function is to convert electronic control signals into mechanical actions, adjust fuel supply or steam valve opening, and achieve speed/load control.

Core components and technical specifications of the product

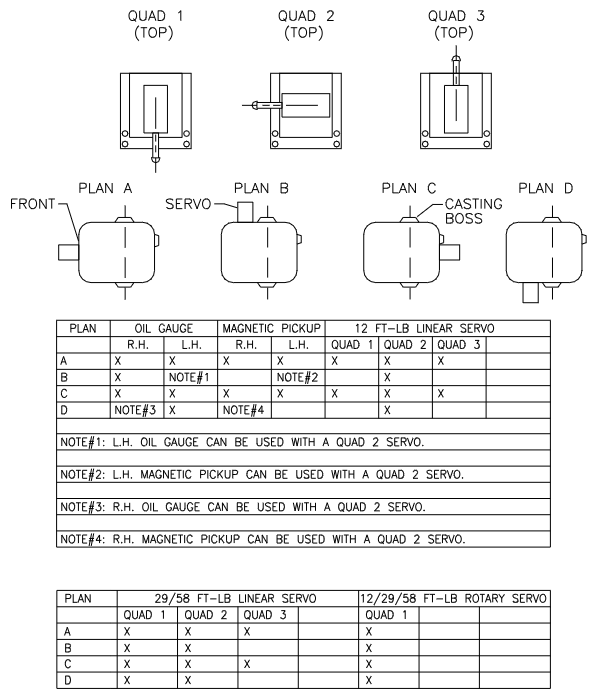

The PGPL system consists of two parts: the "actuator" and the "driver". The former is responsible for mechanical action output, while the latter realizes electrical signal conversion and closed-loop control. The specific parameters are as follows:

1. Actor: the core of mechanical action

(1) Core configuration and performance

Description of Key Parameters for Categories

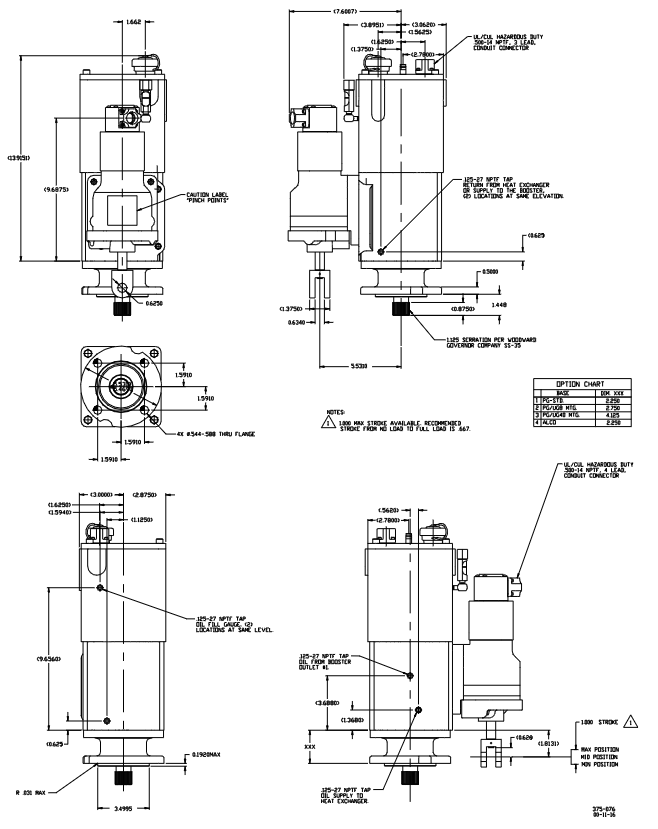

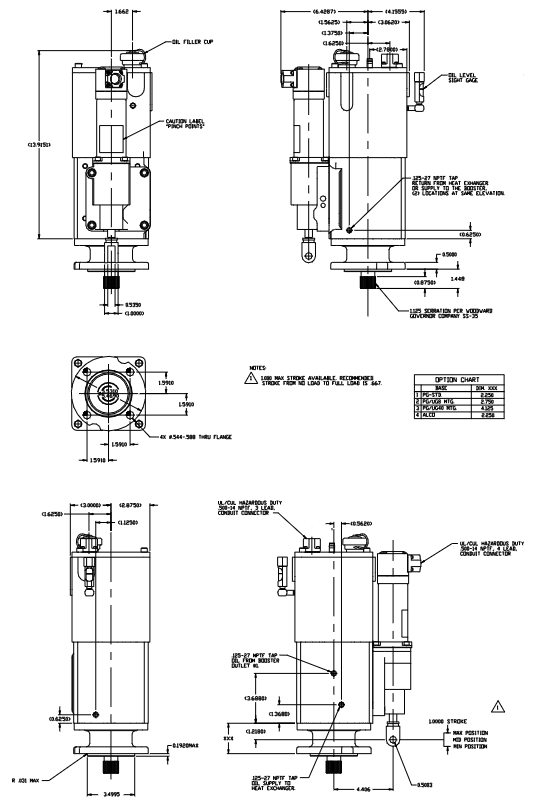

Linear output of power cylinder: 16J (12ft lb), 23J (17ft lb), 39J (29ft lb), 79J (58ft lb)

Rotation output: 16N · m (12lb ft), 23N · m (17lb ft), 39N · m (29lb ft), 79N · m (58lb ft) linear stroke 25mm (1 inch), rotation stroke 30 °; Available travel/output is 2/3 of the maximum value

Hydraulic system oil pump: PG spur gear pump (low-speed version 0.812 inches thick, ≤ 1000rpm); High speed version 0.562 inches thick,>1000rpm)

Working pressure: Standard 896kPa (130psi), 58ft lb model 1655kPa (240psi) with built-in oil tank (2.5L/2.6 quarts), requires separate oil selection (refer to manual 25071)

Drive required speed: 200-1000rpm (bidirectional rotation, with check valve); Maximum 1500rpm (unidirectional, with plug)

Power: Maximum 375W (0.5hp), oil cooler needs to be selected for high speed or high ambient temperature

Position feedback non-contact Hall effect sensor outputs 3.6-4.4Vdc feedback voltage to the driver, achieving closed-loop control

Environmental adaptability working temperature: -29~+104 ℃ (-20~+220 ℉, limited by oil temperature)

Vibration resistance: Complies with WGC RV2 standard, maximum 7G parallel direction of drive shaft. Shell material: base/column made of cast iron, feedback shell made of aluminum alloy, internal parts made of surface hardened steel

(2) Optional Features

Oil cooler: It needs to be installed when the actuator temperature exceeds 93 ℃ (200 ℉), and is divided into internal and external types;

Booster servo motor: using starting air to provide instant oil pressure, assisting equipment to start quickly;

Magnetic electric sensor (MPU): 1-2 optional, detects the speed of the prime mover through the drive shaft of the governor (cannot be used as a component of the overspeed protection system).

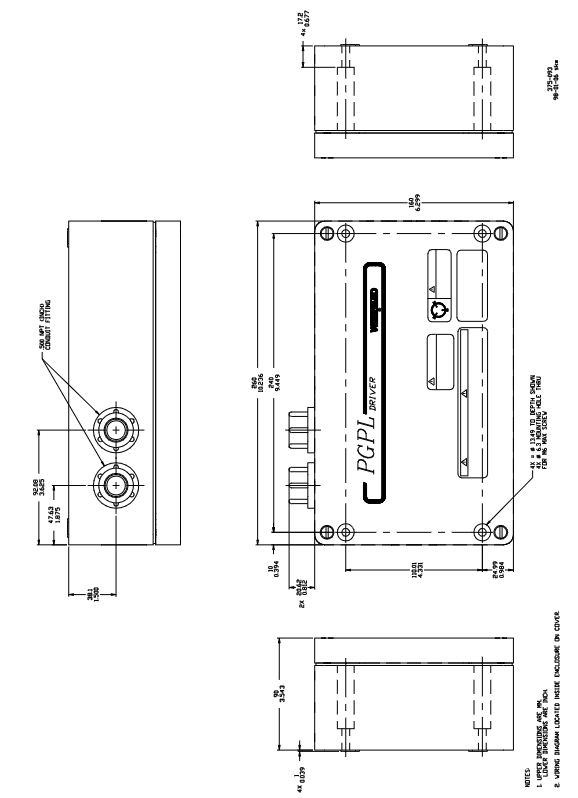

2. Driver: Electrical signal conversion core

(1) Core configuration and performance

Description of Key Parameters for Categories

Electrical signal input/output input: 18-32Vdc power supply, 0-200mA control signal (from electronic speed controller)

Output: 0-200mA drive signal (to actuator torque motor), 4-20mA position feedback signal (to indicator), built-in 210mA current limit to protect torque motor

The closed-loop control receives the 3.6-4.4Vdc signal from the actuator position sensor. After comparing the control signal, the output is adjusted and calibrated before leaving the factory. No field adjustment is required

Installation and environmental enclosure: cast aluminum box (cannot be directly installed on the prime mover)

Working temperature: -40~+70 ℃ (-40~+158 ℉)

Wiring: Use temperature resistant wires with a temperature rating of ≥ 90 ℃, comply with Class I, Zone 2 wiring standards, and require grounding to avoid electromagnetic interference (EMI). Refer to manual 50532

Wire length limit 16AWG (1.5mm ²): battery driver 457m, driver actuator 457m

14AWG (2.5mm ²): Battery driver 610m, driver actuator 610m shielded wire requires twisted pair, one end grounded and the other end suspended

Key requirements for installation and operation and maintenance

1. Installation specifications

(1) Mechanical installation

Attitude: The actuator should be installed vertically or nearly vertically to avoid force on the drive shaft (the actuator should not be placed on the drive shaft);

Transmission connection: The drive shaft should engage freely without any jamming, side load, or excessive axial clearance. The installation bolts should be evenly tightened to avoid shaking;

Connecting rod adjustment: Using 2/3 of the output stroke to achieve "no load full load" adjustment, the remaining stroke is distributed to both ends (ensuring that fuel can be cut off when turned off and maximum fuel can be provided at full load).

(2) Oil selection and maintenance

Oil requirements: viscosity 100-300SUS (at operating temperature), compatible with nitrile, polyacrylic acid, fluorocarbon sealing materials; Recommend using automotive/gas engine oil (such as SAE 10W30, 15W40) to avoid pollution;

Oil change cycle: Under normal working conditions, it should be replaced every year. In harsh environments (high temperature, high pollution), the cycle needs to be shortened; When changing the oil, it is necessary to drain it while it is hot, rinse it with a clean solvent (such as kerosene), and then add new oil.

(3) Electrical installation

Caution in hazardous areas: Do not plug or unplug connectors when live, and replacement parts must meet the requirements of Class I, Zone 2;

Grounding: Drivers and actuators need to be separately grounded to avoid parallel wiring with high voltage/high current wires and reduce EMI interference.

2. Initial operation and troubleshooting

(1) Initial operation steps

Confirm that the oil level is normal, there is no leakage, and the connecting rod is connected correctly;

Set the "low-speed start" mode on the electronic governor and prepare emergency shutdown measures;

Start the prime mover and gradually adjust the governor to the rated speed to ensure that the actuator operates linearly and without any jamming;

Verify closed-loop control: Change the control signal and check if the actuator output matches the feedback signal (10 ± 5mA corresponds to the minimum position, 175 ± 10mA corresponds to the maximum position).

(2) Common faults and solutions

Possible causes of symptoms and solutions

Unable to start/fuel rack does not open, actuator has no electrical signal, oil pump steering error, low oil level, connecting rod stuck. Check power and control signals; Confirm the direction of oil pump rotation; Oil replenishment; Repair the connecting rod

Slow action/delayed response, low speed (<200rpm), improper oil viscosity (too thin/too thick), worn oil pump, increasing speed or installing a boost servo; Replace the compatible oil; Repair/replace oil pump

Calibrate the connecting rod again due to the fluctuation of the prime mover (traveling/surging), nonlinearity of the connecting rod, oil contamination/foaming, and inaccurate parameters of the electronic governor; Change the oil; Adjust the parameters of the speed controller

Overheating of the actuator, high ambient temperature, driving speed exceeding 1500rpm, and installation of an oil cooler for oil oxidation; Reduce the rotational speed; Replace antioxidant oil

Principles of System Control and Safety Design

1. Control logic (closed-loop feedback)

Signal input: The electronic governor outputs a 0-200mA control signal to the driver based on the speed/load requirements;

Signal conversion: The driver converts the control signal into a 0-200mA driving current and sends it to the torque motor of the actuator;

Mechanical action: The torque motor drives the pilot valve, controls the flow of high-pressure oil to the power cylinder, and drives the output shaft action (adjusts the fuel/steam valve);

Feedback loop: The position sensor of the actuator converts the actual position into a 3.6-4.4Vdc voltage signal and feeds it back to the driver; The driver compares the control signal with the feedback signal, adjusts the output current until they match, and achieves precise positioning.

2. Security protection design

Power loss protection: When the control voltage is lost, the torque motor has no magnetic force, the spring pushes the pilot valve to release oil, and the power cylinder resets to the "minimum fuel" position to prevent the prime mover from overspeeding;

Overspeed independent protection: It is explicitly required that the prime mover be equipped with an overspeed shutdown device independent of the PGPL system (not dependent on the MPU of the actuator) to avoid loss of control caused by actuator failure;

Dangerous area protection: The shell is sealed and the wiring meets explosion-proof standards to prevent sparks from igniting dangerous gases.

Product Support and Services

1. Service Options

Quick replacement/exchange: Provide replacement parts of the same model within 24 hours to reduce downtime;

Fixed cost maintenance/renovation: Clearly define the maintenance cost in advance and restore it to a "near new product" state after maintenance;

Spare parts ordering: The model and serial number (indicated on the nameplate) of the actuator/driver must be provided to ensure that the spare parts match.

2. Compliance and Document Reference

Certification: UL (Class I, Zone 2), compliant with EU Machinery Directive 98/37/EC (without CE marking);

Related manuals: 25071 (hydraulic oil selection), 36692 (power cylinder specifications), 36693 (base specifications), 50532 (EMI control).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923