K-WANG

Xycom 4850 LCD monitor 12 inch upgrade with cable kit

Xycom 4850 LCD monitor 12 inch upgrade with cable kit

In the field of industrial automation and equipment operation monitoring, the performance of display devices directly affects the operator's perception and control efficiency of equipment status. The 12 inch CRT monitor originally equipped on the Xycom 4850, although played an important role in the past, gradually exposed many drawbacks with the continuous advancement of technology. CRT monitors have problems such as high power consumption, large size, limited image clarity, and susceptibility to image flickering, which not only affect the visual experience of operators, but long-term use may also lead to eye fatigue, thereby affecting work efficiency. Moreover, CRT technology is becoming increasingly outdated, the supply of related components is gradually decreasing, and the difficulty of equipment maintenance and repair is constantly increasing.

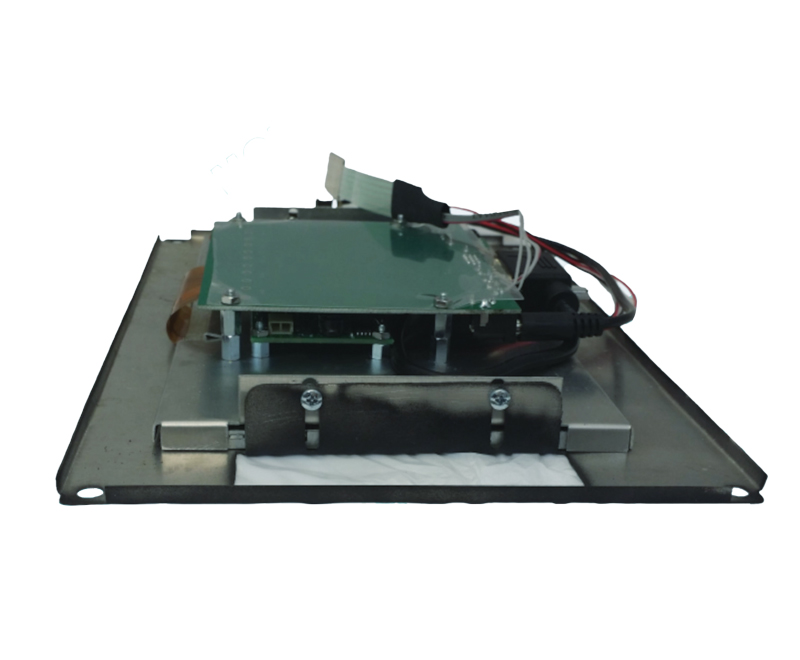

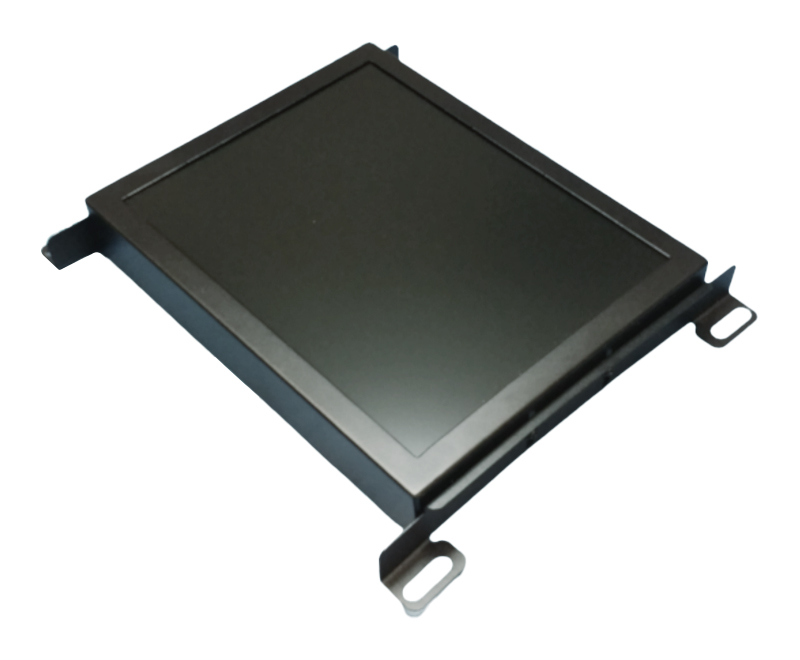

Upgrade kit composition

(1) 10.4-inch LCD screen

The core component in the upgrade kit is a 10.4-inch LCD screen. This screen adopts advanced LCD display technology, which has higher resolution compared to traditional 12 inch CRT screens and can present clearer and more delicate images. Whether it is complex equipment operation parameter charts or fine production process monitoring screens, they can be clearly displayed, allowing operators to obtain information more accurately. At the same time, the color reproduction of LCD screens is better, which can present richer and more realistic colors, helping operators to more intuitively judge the device status. In addition, the screen also has excellent viewing angles, and when viewed from different directions, the clarity and color of the image will not show significant distortion, making it convenient for multiple people to view device information simultaneously.

(2) MK018 cables and other accessories

To ensure seamless connection between the upgraded LCD screen and the existing Xycom 4850 system, the upgrade kit is equipped with MK018 cable. This type of cable is specially designed to have good electrical performance and stability, capable of efficiently transmitting image signals and control signals, ensuring the stability and smoothness of screen display. At the same time, the kit also includes a series of other necessary accessories, such as mounting brackets, fixing screws, etc. The design of the installation bracket fully considers the compatibility with the original CRT display installation position, which can easily and quickly install the LCD screen on the original equipment frame without the need for large-scale structural modifications, greatly reducing installation difficulty and cost. The fixing screws and other accessories are made of high-quality materials to ensure that the installed screen is firm and reliable, and there will be no looseness or displacement during the operation of the equipment.

(3) Installation Guide

Considering the actual needs of users during the upgrade process, a detailed installation guide is included in the upgrade kit. The installation guide guides users step by step through the entire process from removing the original CRT monitor to installing a new LCD screen and related accessories in the form of illustrations and text. For each installation step, there are clear text instructions and corresponding image examples, so even non professional technicians can smoothly complete the upgrade installation work according to the guide. The installation guide also provides common problem answers and troubleshooting methods to help users solve problems in a timely manner, ensuring the smooth progress of the upgrade work.

Detailed explanation of installation process

(1) Dismantle the original CRT monitor

Before starting to install the upgrade kit, it is necessary to ensure that the equipment is powered off to ensure the personal safety of the operators. Then, carefully remove the original 12 inch CRT monitor according to the installation instructions. Usually, it is necessary to first unscrew the screws that secure the monitor, which are usually distributed on the frame or back of the monitor. When removing screws, be careful to store them properly to avoid loss. Next, carefully unplug various cables connected to the CRT monitor, including video signal cables, power cords, etc. When plugging and unplugging cables, excessive force should be avoided to prevent damage to cable interfaces or internal circuits of equipment. The removed CRT monitor should be properly placed for future processing.

(2) Install a new LCD screen and accessories

Installation bracket fixation: Remove the installation bracket from the upgrade kit and install it in the installation position of the original CRT monitor according to the instructions in the installation guide. Use the matching fixing screws to securely fix the bracket to the equipment frame, ensuring that the bracket is installed firmly and will not shake. When fixing screws, it is important to use appropriate tools and tighten them to the specified torque to avoid instability of the bracket or damage to the equipment frame caused by loose screws.

LCD screen installation: Carefully install the 10.4-inch LCD screen onto the fixed bracket. The installation method of the screen usually adopts buckle or screw fixation. For specific installation methods, please refer to the installation guide. When installing the screen, pay attention to the correct orientation of the screen to ensure that the image is displayed properly. During the installation process, avoid colliding or squeezing the screen to avoid damaging it.

Cable connection: Connect one end of the MK018 cable to the signal input interface of the LCD screen, and the other end to the corresponding output interface of the Xycom 4850 system. Ensure that the cable connection is secure and there is no looseness at the interface. At the same time, check other cables that may need to be connected, such as power cords, and connect them in the correct way. When connecting cables, pay attention to the shape and labeling of the interface to avoid inserting the wrong interface, which may cause equipment damage or malfunction.

(3) Debugging and Testing

After completing all hardware installations, power on the device and debug and test the upgraded display system. Firstly, observe whether the LCD screen can light up normally and whether there is any image displayed on the screen. If the screen cannot light up, it may be due to a power connection problem or device malfunction, and it is necessary to follow the troubleshooting methods in the installation guide for inspection and repair. If the screen can light up but the image display is abnormal, such as screen flickering, black screen, image distortion, etc., it may be a signal connection or setting problem. You can check whether the cable connection is firm and whether the device's display settings are correct. By testing various functions of the device, such as viewing device operating parameters, monitoring production process screens, etc., ensure that the upgraded display system can work properly and meet actual usage needs.

Performance improvement after upgrade

(1) Image display optimization

After upgrading to an LCD screen, the image display effect has been significantly optimized. Higher resolution makes device operating parameters, monitoring images, and other details clearer, allowing operators to read data and observe device status more accurately. For example, in industrial automation production lines, for some production processes that require high-precision control, clear image display can help operators detect subtle deviations in equipment operation in a timely manner, adjust production parameters in a timely manner, and ensure product quality. Moreover, the flicker free feature of LCD screens effectively reduces eye fatigue for operators, allowing them to focus on device monitoring work for a long time and improve work efficiency. In addition, good color reproduction can visually display different device states through colors, making it convenient for operators to quickly determine whether the device is operating normally.

(2) Energy consumption reduction and stability enhancement

Compared to CRT monitors, LCD screens have significantly reduced energy consumption. This not only helps enterprises reduce energy costs, in line with the development trend of modern industrial energy conservation and environmental protection, but also reduces the heat generation during equipment operation and lowers the risk of equipment failure due to overheating. At the same time, LCD screens have stronger stability and do not suffer from image quality degradation caused by aging electron guns or other issues with CRT monitors. In industrial environments, equipment may require long-term continuous operation, and LCD screens can maintain stable display performance to ensure the continuity and reliability of equipment monitoring work. For example, in some chemical production equipment that operates continuously for 24 hours, the upgraded LCD display system can work stably, providing operators with continuous and accurate equipment status information.

(3) Compatibility and long-term use advantages

The Xycom 4850 LCD monitor 12 inch upgrade kit was designed with full consideration for compatibility with the original system. The upgraded display system can work perfectly with other components of the Xycom 4850 without system failures or instability caused by compatibility issues. Moreover, with the development of technology, LCD technology continues to mature, and the supply of related components is more stable. This means that in the long term in the future, users do not need to worry about equipment being unable to be repaired due to aging or damage of display components. Compared with the gradually phased out CRT technology, the upgraded LCD display system has a longer service life and better maintainability, providing users with more reliable long-term use guarantee.

Comparison of similar products in the market

In the market, products for upgrading industrial displays are not uncommon, but the Xycom 4850 LCD monitor 12 inch upgrade kit stands out with its unique advantages. Compared to some other brands' upgrade kits, this kit performs better in terms of compatibility. It is specifically designed for the Xycom 4850 system, ensuring seamless integration with the original system, while some generic upgrade kits may have compatibility issues with specific devices, requiring additional debugging and adaptation work from users. In terms of display performance, the 10.4-inch LCD screen used in this kit has obvious advantages in resolution, color reproduction, and viewing angle, which can provide clearer and more realistic image display. However, the display effect of some similar products may not meet the industrial production's demand for high-precision images. In addition, in terms of price, the Xycom 4850 LCD monitor 12 inch upgrade kit has a high cost performance ratio while ensuring product quality and performance. Compared to some similar products with higher brand premiums, it can save users costs.

User case sharing

A large automobile manufacturing enterprise widely uses the Xycom 4850 control system on its production line. The original 12 inch CRT monitor has experienced problems such as image blurring and flickering during long-term use, which seriously affects the monitoring and production efficiency of the equipment by operators. To address this issue, the company has decided to upgrade its display system using the Xycom 4850 LCD monitor 12 inch upgrade kit. After the upgrade is completed, the operator feedback shows that the display effect has been greatly improved, and the operating parameters of the equipment are clear at a glance. Various faults and abnormalities on the production line can be detected and handled more timely. According to statistics, the upgraded production line has improved production efficiency by 15% and reduced product defect rate by 10% due to more accurate equipment monitoring, bringing significant economic benefits to the enterprise.

Another electronic device manufacturing company upgraded its display system, which not only improved the monitoring efficiency of the production process, but also saved a lot of costs in equipment maintenance. Due to the higher stability and reliability of LCD screens, device downtime caused by display issues is significantly reduced. Moreover, the installation process of the upgrade kit is simple and fast, and the technical personnel within the enterprise have successfully completed the upgrade work according to the installation guide, without causing too much impact on normal production. The relevant person in charge of the enterprise stated that this upgrade is a very successful investment, effectively improving the production and operation level of the enterprise.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923