K-WANG

Lennox ZHA series heat pump complete set (507257-01b)

Electrical safety: power-off operation is a prerequisite - the power supply of the unit must be turned off during any maintenance to avoid the risk of electric shock or explosion; Before powering on, it is necessary to confirm that the voltage meets the range indicated on the nameplate, and the three-phase power supply must ensure phase balance (especially for models with frequency converters).

Lennox ZHA series heat pump complete set (507257-01b)

Core Security and Basic Instructions

1. Safety warning (highest priority)

Operation qualification: It is explicitly required that installation, commissioning, and maintenance must be carried out by licensed HVAC professionals or equivalent service organizations. Improper operation may result in property damage, personal injury, or even death.

Electrical safety: power-off operation is a prerequisite - the power supply of the unit must be turned off during any maintenance to avoid the risk of electric shock or explosion; Before powering on, it is necessary to confirm that the voltage meets the range indicated on the nameplate, and the three-phase power supply must ensure phase balance (especially for models with frequency converters).

Refrigerant compliance: In accordance with the 1990 Clean Air Act, intentional discharge of CFCs and HCFCs refrigerants is prohibited, and compliant methods such as recycling, regeneration, or reuse must be adopted. Violation may result in fines or imprisonment.

Roof protection: The unit contains refrigerant and engine oil, and some rubber roof materials may absorb engine oil, causing expansion and leakage. During installation and maintenance, the roof surface should be protected to avoid direct contact.

2. Basic parameters and applicable scope

Unit specifications: Cooling capacity covering 7.5-10 tons, optional distribution heating module; Some models support air supply frequency converters, which can automatically adjust the fan speed according to the load during cooling (low load low speed, high load high speed). When the fan runs alone, it is at low speed, and when heating, it is at high speed.

Installation restrictions: It is prohibited to use the unit as temporary heating/cooling equipment during the construction phase. Low temperature return air, harmful gases, or clogged filter elements can damage the unit; If used in violation of regulations, specific conditions must be met (such as thermostat control, installation of pre filters, etc.), otherwise the warranty will be invalidated.

Core installation process and technical requirements

1. Preliminary preparation: Packaging inspection and installation clearance

Packing list: A single package contains one assembled unit. Upon receipt, it is necessary to immediately inspect for transportation damage. If there are any issues, contact the final carrier.

Installation clearance (key dimensions): It is necessary to strictly follow the operation and operation clearance around the unit to ensure heat dissipation and maintenance space, as shown in the following table:

|Gap Type | A (inches/millimeters) | B (inches/millimeters) | C (inches/millimeters) | D (inches/millimeters) | Top Gap|

|Maintenance gap | 36 (914) | 36 (914) | 60 (1524) | 36 (914) | unobstructed|

|Minimum operating clearance | 36 (914) | 36 (914) | 60 (1524) | 36 (914) | unobstructed|

2. Unit support and fixation

According to the direction of air supply (downward air supply/horizontal air supply), the support requirements vary, and the core is to ensure that the unit is level, leak proof, and corrosion-resistant:

Down air supply application: can only be installed on non flammable surfaces; If installed on flammable surfaces, it is necessary to use Z1CURB roof installation frame, which should be horizontal (with an error of ≤ 1/16 inch per linear foot, or ≤ 5 millimeters per meter) and sealed and fixed to the roof.

Horizontal air supply application: The top of the support platform should be about 4 inches (102 millimeters) above the ground to avoid water accumulation; The supporting structure needs to be built along the four sides of the unit base, made of steel or anti-corrosion treated wood, with a recommended minimum height of 14 inches (356 millimeters) to prevent moisture from entering.

General requirements: The air duct should be connected to the roof frame rather than the unit itself, and the return air static pressure box should be installed before the unit is in place.

3. Lifting and positioning (to avoid structural damage)

Lifting parameters: The maximum weight of the unit (including all accessories) is 1270 pounds (576 kilograms), and 4 cables need to be used to connect the base track holes, along with the "H-shaped lifting device" provided on site to prevent deformation of the unit.

Key steps:

Remove the wooden base protection board before lifting;

Connect the two holes at each corner of the cable base to ensure that all panels are installed in place before hoisting;

After partially lifting the unit, remove 5 L-shaped brackets that fix the protective substrate;

The new roof curb (length 89-3/8 inches) requires the removal of 3 positioning brackets, while the old curb (length 81-3/4 inches) needs to be positioned with positioning brackets as shown in the diagram.

4. Connection between condensate discharge and air duct

Condensed water drainage: The unit is equipped with a 1-inch NPT drainage interface, and the drainage pan is made of fiberglass reinforced engineering plastic. When connecting, the pipe joint needs to be manually tightened and then an additional 1/4 turn should be added to avoid damage caused by excessive force; A trap must be installed, and the drainage pipeline must have a slope of 1 inch (25 millimeters) every 10 feet (3 meters), in accordance with local drainage regulations.

Air duct requirements: Outdoor air ducts, joints, and roof/wall openings need to be insulated and waterproofed (using waterproof boards and sealant); Air ducts passing through non air conditioned areas must be insulated; Drilling holes in the base of the unit is prohibited in the application of down air supply to prevent roof leakage.

5. Electrical connection (including special model requirements)

Power wiring:

The 230/460/575V models are factory pre wired, and for 208V power supply, all pink (230V) wires of the control power transformers need to be disconnected, reconnected, and the exposed 230V wire ends wrapped;

The power cord needs to be introduced from the bottom entry area and connected to the L1, L2, and L3 terminals of TB13 in the control box. If there is an S48 isolation switch (pre installed in the factory), it needs to be connected according to the wiring diagram.

Three phase voltage balance (with frequency converter model): The frequency converter relies on a balanced three-phase power supply. If the power supply is unbalanced, a higher current level frequency converter needs to be replaced (refer to Table 1:5HP → 7.5HP → 10HP gradually upgraded), otherwise it will reduce the reliability of electrical components.

Thermostat installation:

Location: Vertically installed on a 2 × 4 inch junction box or non-conductive surface, with a height of approximately 5 feet (1524 millimeters), avoiding areas such as air vents, direct sunlight, and electrical radiation;

Wiring: Use 18AWG wire, and non high voltage rated thermoelectric wires should be kept away from the power line and secured with a wire tie in the lower left corner of the control area.

Run debugging and parameter setting

1. Pre startup inspection (mandatory steps)

Confirm that the installation complies with the instructions and local regulations, and that all electrical wiring (factory+on-site) is not loose;

Check that there is no friction in the refrigerant pipeline (avoid contact with the cabinet or other pipelines);

Confirm that the power supply voltage is within the range indicated on the nameplate. If it does not meet the requirements, contact the power company for adjustment;

Install the filter element and ensure that the thermostat has no heating, cooling, or fan requirements before powering on.

2. Fan operation and adjustment

Phase correction of three-phase compressor: The factory has pre-set the phase (L1 red, L2 yellow, L3 blue), and after starting up, it is necessary to observe the suction and exhaust pressure and the direction of the fan. If there is no pressure difference or the direction is incorrect, the power supply needs to be disconnected and any two on-site connections on the incoming side of K3, TB2 or F4 need to be replaced (it is forbidden to replace the fan contactor or compressor connection).

Fan speed and CFM calculation:

Non variable frequency models: Run the fan when there is no cooling demand, measure the fan shaft speed and the external static pressure (between the supply and return air) of the unit, and refer to the fan data sheet on pages 10-12 to determine the CFM;

Variable frequency model: High voltage switches S4 and S7 need to be disconnected to trigger Y1/Y2 and run the fan at high speed, then measure and calculate;

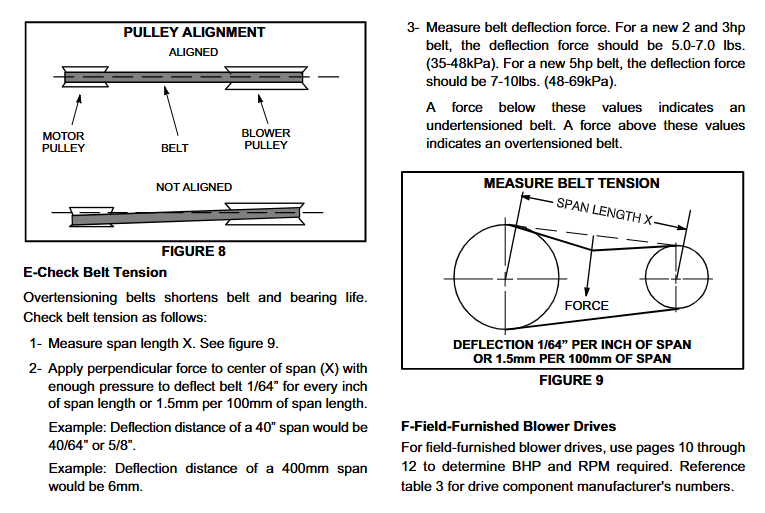

Speed adjustment: It is achieved through the motor pulley. Clockwise rotation of the adjustable pulley increases CFM, while counterclockwise rotation reduces CFM. The minimum/maximum rotation number of the belt should be observed (0-5 turns for A-type belt, 1-6 turns for B-type belt, and there is no minimum rotation limit for B-type belt pulleys over 6 inches).

Belt tension adjustment: The new belt needs to be re tensioned after running for 24-48 hours. The tension standard is: 2-3HP belt deflection force 5.0-7.0 pounds (35-48kPa), 5HP belt 7-10 pounds (48-69kPa), deflection amount of 1/64 inch per inch span (1.5 millimeters per 100 millimeters span).

3. Heating and cooling start-up

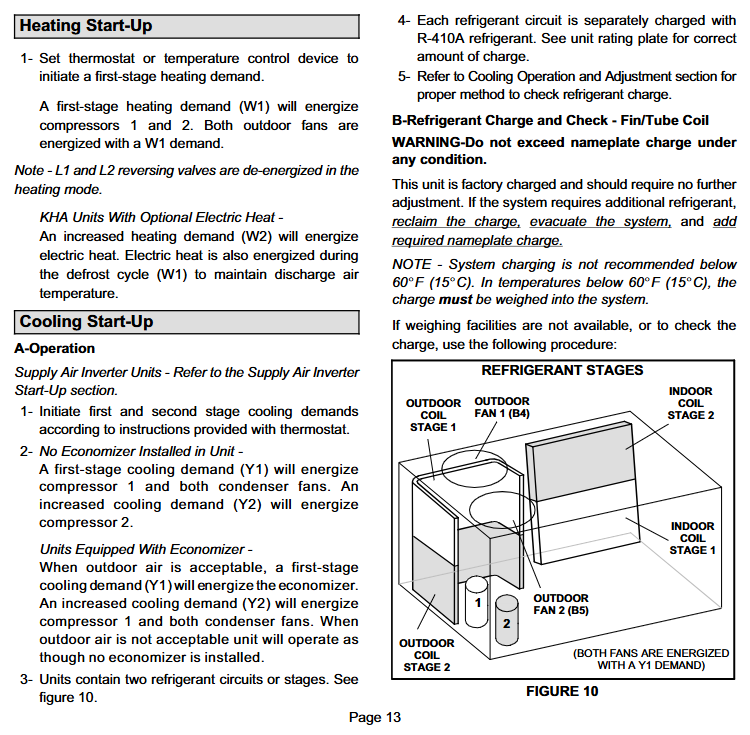

Heating start: Set the thermostat to level one heating (W1), triggering the operation of compressors 1 and 2 and the outdoor fan (power off L1 and L2 reversing valves in heating mode); If there is optional electric heating, the secondary heating (W2) will activate the electric heating, and the electric heating will also be activated during the defrosting cycle (W1) to maintain the supply air temperature.

Refrigeration start:

Model without energy-saving device: compressor 1 and two condenser fans are activated for primary refrigeration (Y1), and compressor 2 is activated for secondary refrigeration (Y2);

Model with energy-saving device: When the outdoor air meets the conditions, Y1 activates the energy-saving device first, and Y2 activates compressor 1 and fan when the load increases;

Refrigerant inspection: The unit factory pre charges R-410A without the need for additional charging; If it is necessary to supplement, the original refrigerant should be recovered and vacuumed first, and then filled according to the amount indicated on the nameplate (weighed and filled below 60 ° F/15 ° C). It is forbidden to exceed the nameplate filling amount.

4. Defrost control (core function of heat pump)

Defrost triggering and termination: triggered by the liquid tube temperature (≤ 35 ° F/1.7 ° C), the defrost controller (CMC1) starts defrosting after 60 minutes (100269-02 board) or 90 minutes (100269-04 board) of cumulative heating operation by default, lasting for 14 minutes; If the steam pressure reaches 450 PSI (3103 kPa), the defrost pressure switch will prematurely terminate defrosting.

Defrost time adjustment: The defrost interval can be set to 30/60/90 minutes through the jumper on the CMC board. The factory defaults to 60 minutes, and when there is no jumper, it defaults to 90 minutes.

Diagnostic LED: The defrost board has 2 LED lights, and the status is determined by flashing mode (normal operation: synchronous flashing; no power/board fault: all off; board fault: all on; anti short cycle lock: alternate slow flashing).

Maintenance and Service Standards

1. Regular maintenance cycle and content

Annual inspection (performed by professionals):

Filter element: The unit comes with a 20 × 24 × 2 inch temporary filter element at the factory. Before the building is put into use, it needs to be replaced with a compliant filter element (which requires U.L.C certification in Canada). It will be inspected monthly and replaced when it is dirty; When replacing, open the access door of the filter element on the back of the unit, lift the filter element stopper to remove it, and pay attention to the airflow direction markings.

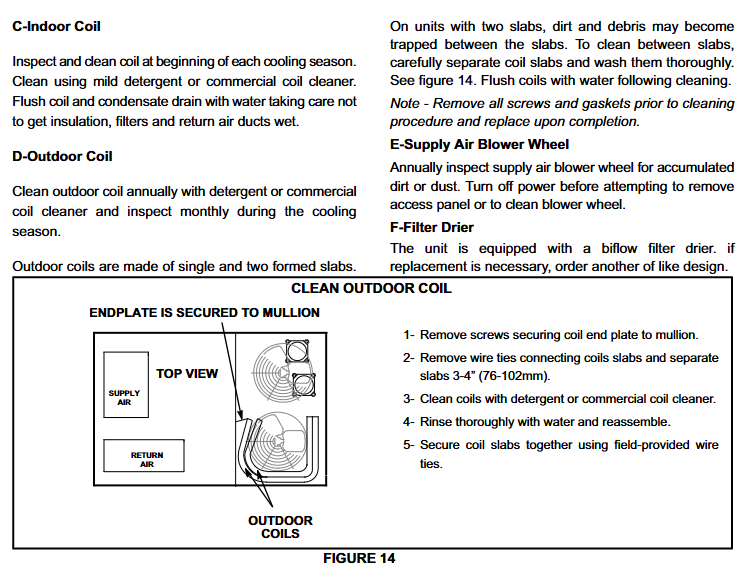

Coil cleaning: Clean indoor coils before the start of the cooling season (using neutral or commercial coil cleaners, and avoid soaking insulation materials, filter elements, and return air ducts during flushing); The outdoor coil is cleaned annually, and the double slab coil needs to remove screws and washers, separate 3-4 inches, clean the interlayer, and then reassemble.

Fan wheel: Check the dust accumulation on the supply fan wheel every year, and remove the maintenance door for cleaning after power failure.

Maintenance free components: All motors are pre lubricated by the factory and do not require subsequent refueling; If the bidirectional drying filter needs to be replaced, the same model of product should be selected.

2. Precautions for troubleshooting

During maintenance, all wires should be marked before disconnecting to avoid wiring errors;

Refer to the "Defrost Control Board Diagnostic LED" and "Normal Operating Pressure Gauge" (Table 4-6, covering the suction and exhaust pressure range at outdoor temperatures of 65-115 ° F) to determine if the compressor, fan, and other components are functioning properly;

If the unit is used for temporary temperature control during construction, it must meet the conditions of "thermostat control, installation of pre filter, return air temperature 13-27 ° C", otherwise the warranty will be invalid, and the heat exchanger, air duct, filter element and other components must be thoroughly cleaned after construction is completed.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923