K-WANG

Siemens 6AV6645-0CB01-0AX0 Mobile Panel

Product Name SIMATIC MOBILE PANEL 277 (7.5-inch mobile panel, integrated enable button and emergency stop button, meeting safety operation requirements)

Core functions include human-machine interaction in industrial sites, supporting equipment monitoring (such as process parameter display and alarm viewing), operation control (such as parameter input and instruction issuance), and adapting to mobile operation scenarios (such as production line inspection and equipment debugging)

The compatibility of the configuration tool supports two types of mainstream configuration software:

-WinCC flexible: Standard Version 2005 SP1 and above, Advanced version;

-TIA Portal: Comfort, Advanced, Professional versions (V11 and above), Basic version not supported

Siemens 6AV6645-0CB01-0AX0 Mobile Panel

Product Core Basic Information and Positioning

Basic identification and functional positioning

Specific project content

Ordering Number 6AV6645-0CB01-0AX0 (core ordering identifier, belonging to SIMATIC MOBILE PANEL series mobile HMI)

Product Name SIMATIC MOBILE PANEL 277 (7.5-inch mobile panel, integrated enable button and emergency stop button, meeting safety operation requirements)

Core functions include human-machine interaction in industrial sites, supporting equipment monitoring (such as process parameter display and alarm viewing), operation control (such as parameter input and instruction issuance), and adapting to mobile operation scenarios (such as production line inspection and equipment debugging)

The compatibility of the configuration tool supports two types of mainstream configuration software:

-WinCC flexible: Standard Version 2005 SP1 and above, Advanced version;

-TIA Portal: Comfort, Advanced, Professional versions (V11 and above), Basic version not supported

Key hardware and display characteristics

Hardware and display performance directly affect the operating experience and on-site adaptability. The document specifies the core parameters in detail

1. Display system

Display specific specifications of parameters

Screen specifications - size: 7.5 inches (diagonal of screen);

-Type: TFT color LCD display screen;

-Resolution: 640 × 480 pixels (VGA level, meeting the clear display requirements of industrial parameters)

Color and Grayscale - Number of Colors: 65536 (True Color, Supports Rich Interface Design);

-Grayscale level: 65536, smooth transition of the image

Backlight lifespan MTBF (Mean Time Between Failures) is approximately 50000 hours (at 25 ℃), and long-term use does not require frequent backlight replacement

2. Operation control components

Supports "button+touch" dual operation mode, adapted to different industrial operation habits, and has safety control buttons:

Specific specifications of operating components

Function keys - Quantity: 18 programmable function keys, all with LED indicator lights (real-time display of key status, such as active/inactive);

-Features: Supports custom engraved film buttons, and can annotate functions according to needs (such as "start", "stop", "parameter settings")

Touch function - type: analog resistive touch screen (industrial grade durability, supports glove operation);

-Calibration: Supports touch calibration function to ensure operational accuracy

Safety Button - Stop Button: Integrated, meets industrial safety standards, and can quickly cut off dangerous operations in emergency situations;

-Enabling Button: Integrated, requires pressing to activate operation, preventing accidental touch

Other inputs - supports numeric/alphabetical/hexadecimal input;

-Support 2 sets of multi key operations simultaneously to improve operational efficiency

3. Core hardware configuration

Specific specifications of hardware parameters

Processor ARM architecture, 520MHz main frequency (meets the interface refresh and data processing requirements of industrial HMI)

Storage Capacity - Main Memory (RAM): Maximum 128MB;

-User data available memory: 6MB;

-Extended Storage: Supports 1 MMC/SD card slot (expandable storage for archiving logs, backup configuration)

Real time clock hardware clock, with battery backup and support for synchronization (ensuring time accuracy for logging and task scheduling)

Communication interface and protocol compatibility

As an industrial HMI, it needs to communicate with multiple controllers and devices, and the documentation clearly states its rich interface and protocol support:

1. Physical interface

Specific specifications of interface type

Industrial bus interface -1 × RS422 (suitable for high-speed, long-distance serial communication, such as connecting encoders and frequency converters);

-1 × RS485 (supports multi device networking, such as connecting PLC and sensors);

-1 x Industrial Ethernet (RJ45 interface, maximum transmission rate of 12Mbit/s, used for high-speed data exchange)

Universal interface -1 x USB interface (supports connecting external devices such as mouse, keyboard, barcode reader, USB flash drive, etc.);

-No parallel interface

2. Support protocols

Covering mainstream industrial buses and Ethernet protocols, compatible with multiple brands of controllers:

Specific support for protocol categories

Ethernet Protocol - TCP/IP (Basic Network Protocol, used for configuring transmission and remote monitoring);

-PROFINET IO (Siemens Industrial Ethernet protocol, supporting real-time data exchange)

Serial bus protocol - PROFIBUS DP (Siemens mainstream fieldbus, connecting S7-300/400 and other PLCs);

-MODBUS (Universal Industrial Protocol, compatible with devices from brands such as Modicon and OMRON)

Other compatible supports AS-i, CAN, INTERBUS and other protocols (with corresponding drivers), can connect to multiple brands of controllers such as S5, S7-200/1200/1500, Allen Bradley, Mitsubishi, etc

Industrial environment adaptability and safety compliance

1. Environmental tolerance

Specific specifications of environmental parameters

Temperature range - Operating temperature: 0~+40 ℃ (suitable for most industrial workshop environments);

-Storage/transportation temperature: -20~+60 ℃, suitable for logistics and warehousing needs

Protection level: IP65 (dustproof, waterproof, suitable for use in humid and dusty industrial sites)

Drop resistance: Drop height of 1.2 meters (non packaged state, not easily damaged by accidental drop, improving on-site durability)

Maximum relative humidity tolerance of 80% (without condensation), suitable for high humidity environments (such as food processing and water treatment workshops)

2. Safety and compliance certification

Compliance category specific certification

Safety level - compliant with EN ISO 13849-1:2008 standard, performance level PL d (meeting industrial safety control requirements);

-Safety category complies with EN954-1 (for emergency stop and enable buttons)

International certifications CE (EU Access), cULus (US Canada Access), C-TICK (Australia Access), SIBE (German Safety Certification), supporting global use in multiple regions

Software functions and configuration features

1. Core software functions

Specific specifications for functional categories

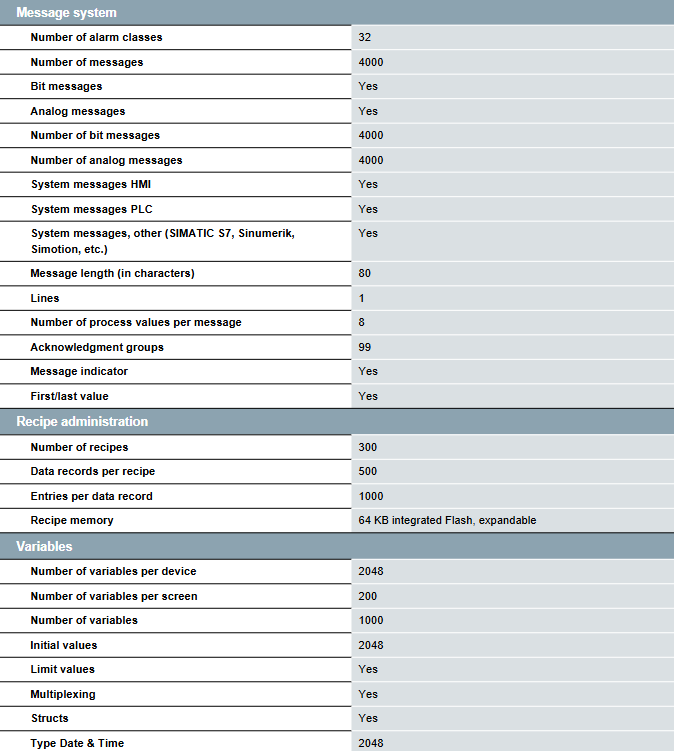

Monitoring and Alarm - Supports 4000 alarm messages (including bit alarms and analog alarms), with 32 alarm levels;

-Equipped with an alarm log system (including caching and confirmation functions), capable of recording alarm time, type, parameters, and supporting 99 confirmation groups

Formula management - supports 300 formulas, each containing 500 data records, with 1000 entries per record;

-Formula storage: 64KB integrated Flash, expandable through MMC/SD card

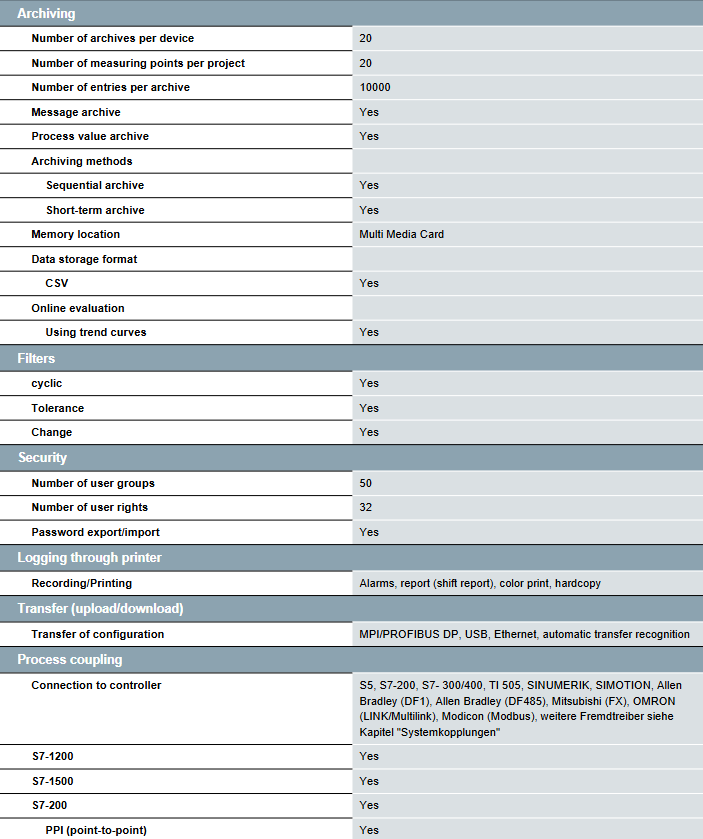

Data archiving - supports 20 archive files, with a maximum of 10000 records per archive;

-Archive types: alarm archive, process value archive;

-Storage format: CSV (convenient for offline analysis using software such as Excel)

Variable management - supports 2048 device variables, with a maximum of 200 variables per screen;

-Support initial and limit value settings for variables, support Structs and date time types

2. Configuration and maintenance

Specific specifications of configuration features

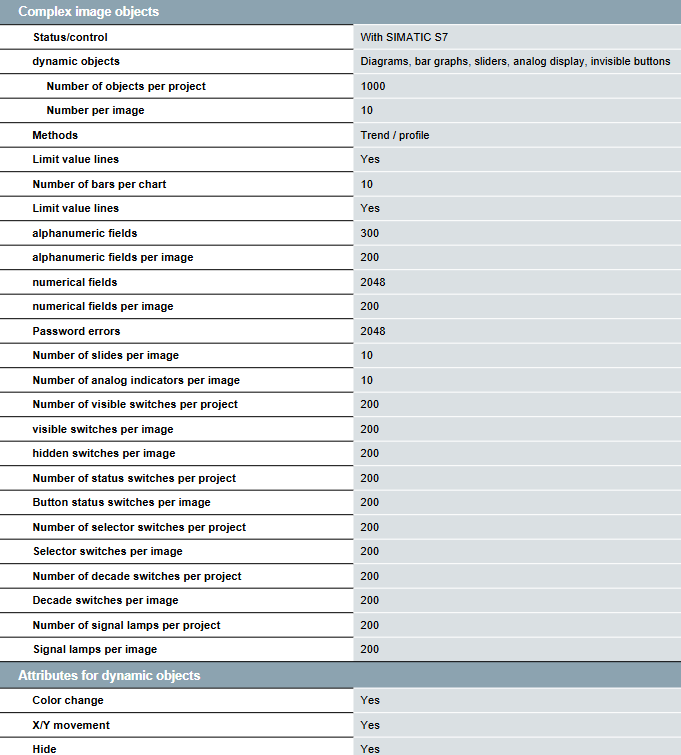

Interface design - supports 500 configurable screens and dynamic objects (such as trend charts, bar charts, sliders);

-Supports 16 online running languages and 32 project languages, suitable for multilingual workshops

Data transmission - Configure transmission methods: MPI/PROFIBUS DP, USB, Ethernet, supporting automatic transmission recognition;

-Support Delta transfer to reduce configuration update time

The maintenance tool supports functions such as screen cleaning, touch calibration, backup/restore, device switching, etc., simplifying on-site maintenance

Physics and other parameters

Specific specifications of physical parameters

Size and weight - shell diameter: 290mm, depth: 103mm (circular design, easy to hold and install);

-Weight (unpackaged): 1.7kg, with good portability

The power supply is provided through a connection box (which needs to be paired with a Siemens dedicated connection box to ensure stable and safe power supply)

Warranty and Support - Warranty Period: 1 year;

-Support free hotline service and provide technical support

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923