K-WANG

Siemens ET200SP 6ES7193-6PA00-0AA0 server module

Document Structure: Includes 8 core chapters: Preface, Document Guide, Product Overview, Parameter/Address Space, Diagnostic Alarm, Technical Specifications, Parameter Data Recording, Dimensional Drawings, along with supporting safety warning system and compliance instructions.

Siemens ET200SP 6ES7193-6PA00-0AA0 server module

Overview and Basic Product Information

(1) Overview

Type: Siemens SIMATIC ET200SP Server Module Operation Manual, version March 2015 (A5E0357537-AB), is a supplementary document to the ET200SP Distributed I/O System Manual, focusing on module specific functions. System level general functions should refer to the ET200SP System Manual (available through specified links).

Document Structure: Includes 8 core chapters: Preface, Document Guide, Product Overview, Parameter/Address Space, Diagnostic Alarm, Technical Specifications, Parameter Data Recording, Dimensional Drawings, along with supporting safety warning system and compliance instructions.

(2) Product Fundamentals

Model and positioning: Model 6ES7193-6PA00-0AA0 is a server module for the ET200SP distributed I/O system. Its core function is to enclose the backplane bus and provide three backup fuses (5 × 20mm) for storage support. It needs to be used in conjunction with specific CPU/interface modules.

Compatibility: Only supports IM 155-6 PN BA interface module (product version ≥ 1, firmware version ≥ V1.1.1), can be configured through STEP 7 (TIA Portal) or GSD file.

Core functions and features

(1) Basic functions

Hardware Assistance: Integrated backup fuse storage location, convenient for quick access to fuses during on-site maintenance, without the need to carry additional spare parts boxes.

System support: Closed ET200SP backplane bus to ensure stable bus signals and avoid external interference; Support firmware updates, I&M identification data storage, and reconfiguration in RUN mode to enhance system flexibility and maintainability.

Status monitoring: It can monitor the power supply voltage (L+) and feedback voltage status of each slot I/O module in real time, and output the monitoring results through the address space, which is convenient for user programs to read and locate faults.

Device replacement optimization: When there is no topology configuration for IM 155-6 PN BA, the device name can be retained, and there is no need to reconfigure the name parameter after replacing the module, simplifying the replacement process.

(2) Key characteristics

Characteristic Details

Parameter configuration supports the "L+Power Loss Group Diagnosis" parameter (can be enabled/disabled, disabled by default). When enabled, 1 diagnostic message will be generated based on the potential group for L+power loss, regardless of the "L+Power Loss Diagnosis" parameter of the I/O module itself

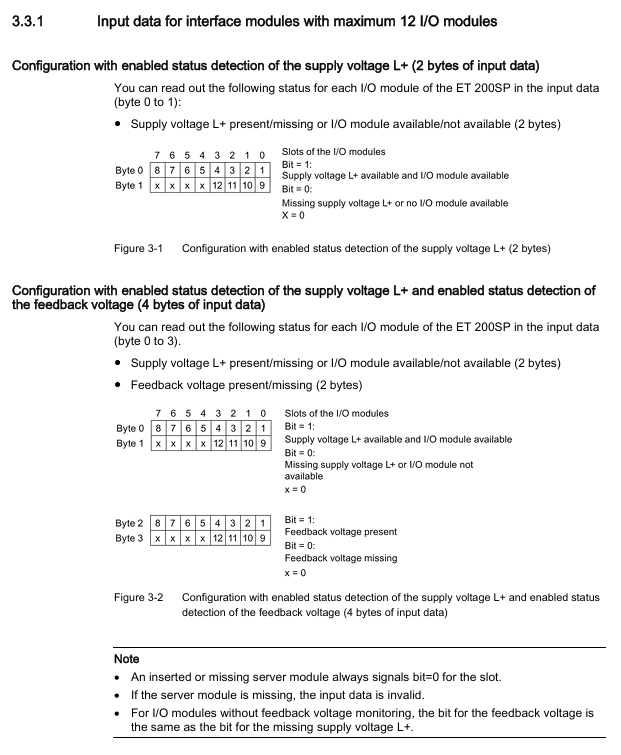

The address space function outputs input data of different lengths based on the maximum number of I/O modules supported by the CPU/interface module (12/32/64 slots). It can choose to monitor only the power supply voltage or monitor both the power supply voltage and feedback voltage simultaneously

Diagnostic alarm is only a type 1 diagnostic alarm (error code 1BH), corresponding to "server module firmware version invalid (<V1.1.1)", which requires module replacement or firmware upgrade to solve

Parameters and Address Space

(1) Parameter configuration

Configurable parameters: Only one parameter, "L+power loss group diagnosis", with a range of "enable/disable", disabled by default, supports reconfiguration in RUN mode (data recording needs to be transmitted through the "WRREC" command).

Parameter validation logic: After activation, the system generates a diagnosis based on the power supply status of the installed I/O modules in the potential group, requiring no empty slots in the potential group; When the light colored BaseUnit (BU.. D) has no I/O module, the potential group will be merged into the previous potential group. After inserting the I/O module, the potential group will be re identified and the diagnosis will be updated.

(2) Address space rules

1. Data length division

According to the maximum number of I/O modules supported by the CPU/interface module, the input data length is divided into three categories, as follows:

The maximum number of I/O modules supported is to monitor only the power supply voltage (in bytes) while monitoring both the power supply voltage and feedback voltage (in bytes). Only the diagnostic address (with no data) is supported

12 slots 2 4 0

32 slots 4 8 0

64 slots 8 16 0

2. Data interpretation rules

Power supply voltage monitoring: Each I/O module corresponds to one bit, bit=1 indicates "L+power supply is normal and the module exists", bit=0 indicates "L+power supply is missing or the module is not installed"; The server module's own slot outputs bit=0 regardless of whether it is installed or not.

Feedback voltage monitoring: Extra bytes of the same length as the supply voltage are occupied, with 1 bit corresponding to each I/O module. Bit=1 indicates "feedback voltage exists", and bit=0 indicates "feedback voltage is missing"; The I/O module without feedback voltage monitoring function has a bit status that is consistent with the "L+power loss" status (i.e. bit=0).

Data validity: When the server module is missing, all input data is invalid, and the module installation status needs to be checked first.

3. Feedback voltage evaluation

Voltage range definition: When L+supply voltage is greater than 6V, the feedback voltage status is included in the input data; When 6V<feedback voltage ≤ 12V or>12V, corresponding to different system fault scenarios (such as cable crossing), the fault type can be determined by reading the bit status through the user program.

Evaluation scenario: Only when the L+power supply is safely disconnected (as indicated by the safety relay status), the feedback voltage bit=1 (6-12V or>12V) can be used as a fault diagnosis basis to locate system circuit abnormalities.

Technical specifications and installation

(1) Mechanical specifications

Parameter Value

Dimensions (width x height x depth) 7mm x 117mm x 36mm

Weight (approximately) 19g

The fuse supports three 5 × 20mm backup fuses

(2) Installation and Connection

Installation method: Suitable for ET200SP standard installation rails, no additional fasteners required, quick installation through rail buckles, compatible with other ET200SP modules in terms of layout.

Connection requirements: No independent I/O terminals, only connected to the system through the backplane bus, no additional wiring required, automatically connected to the system after installation.

Diagnosis and maintenance

(1) Diagnostic alarm processing

Diagnosis alarm type error code reason solution

Invalid firmware version 1BH server module firmware version<V1.1.1, incompatible with the current system. 1. Replace the server module with firmware version ≥ V1.1.1;

2. Firmware update of existing modules (requires specialized tools and processes)

(2) Parameter data recording

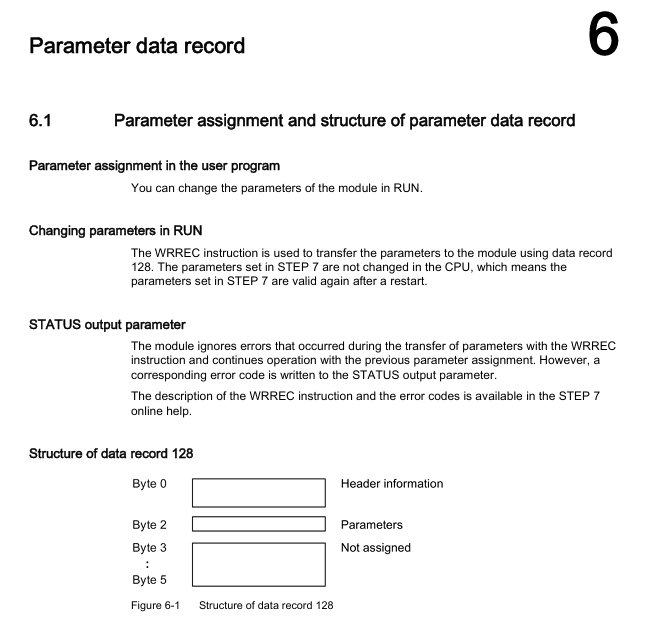

Parameter transmission: To modify parameters in RUN mode, the "WRREC" command is used to write the parameters into data record 128 (bytes 0-5, where byte 2 is the "L+power loss group diagnosis" enable bit, bit=1 enabled).

Error handling: When an error occurs during parameter transmission, the module ignores the error and maintains the original parameter configuration. At the same time, the error code is written into the "STATUS" output parameter. The meaning of the error code can be queried through STEP 7 online help.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923