K-WANG

Sonnax 6R80L-6R100-ZIP Transmission Valve Body Repair Kit

Sonnax 6R80L-6R100-ZIP Transmission Valve Body Repair Kit

Core positioning and scope of application of the product

Sonnax 6R80L-6R100-ZIP is a valve body repair kit (ZIP KIT) designed specifically for Ford 6R80 (2015+) and 6R100 automatic transmissions ®), The core function is to replace key components inside the valve body that are prone to wear and aging, such as sleeves, valves, sealing rings, pistons, etc., to solve common faults such as decreased shifting quality, abnormal pressure control, clutch slippage, etc., and restore the normal working performance of the gearbox. Its typical application scenarios include:

Transmission repair shop: for major repairs or targeted fault repairs of 6R80/6R100 transmissions (such as shifting shock, delay, fault code reporting pressure control beyond range);

Automotive aftermarket: used for performance refurbishment of old vehicle transmissions to extend their service life;

Professional modification field: Provide enhanced maintenance and improve reliability for high mileage or high-intensity use (such as towing, off-road) transmissions.

This kit belongs to the classic "Zip Valve" series of Sonnax. Please note that it is only compatible with 6R80 and 6R100 transmissions produced after 2015, and is not compatible with previous models such as 6R80 (2009-2014) and ZF6HP series (Gen1/Gen2). The valve body model must be confirmed through a dedicated identification guide before use.

Core functions and suite composition

(1) Core maintenance function

The kit is designed around the three core fault points of "pressure control", "shift logic", and "sealing performance" of the 6R80/6R100 valve body. Typical problems that can be solved include:

Abnormal pressure control: unstable, delayed or impacted shifting pressure caused by wear of the main pressure regulator;

Sealing failure: Oil leakage caused by aging of the sealing ring, leading to insufficient clutch oil supply and slipping;

Piston/spring fatigue: Decreased shifting quality caused by the elastic attenuation of the accumulator piston or spring (such as jerking, gear jumping);

Electromagnetic valve adaptation issues: Electromagnetic valve performance failures and fault codes (such as PCA, SSA soleoid related codes) caused by damaged or misaligned sealing rings of the solenoid valve.

(2) Core components of the kit

The kit is divided into component groups according to the installation order, and all parts are Sonnax original compatible parts. The key components are as follows (sorted by installation steps):

Installation steps, component categories, specific specifications and quantities, functional roles

1 pressure regulator sleeve (diameter. 629 "x length. 645") to replace the original worn main pressure regulator sleeve and restore pressure control accuracy

2 sets of valve and sleeve combination (including valve and matching sleeve) repair the clearance between the valve core and sleeve of the clutch control pressure regulator to solve pressure leakage

3 Internal end plugs and sealing rings - Internal end plugs: 4 pieces

-O-ring: 11 (including 3 spare) seals the internal oil passage of the valve body to prevent oil from flowing into the chamber. The end plug needs to be installed with a "perforated surface facing outward"

4 large end plugs and sealing rings - Large end plugs: 4 pieces

-Large O-ring seals: 6 (including 2 spare) to seal the external large-sized oil passage interface of the valve body, suitable for installation in the lower half of the valve body

5 small end plugs and sealing rings -6 small end plugs

-Small O-ring seals: 9 (including 3 spare) to seal the small-sized oil passage interface outside the valve body, suitable for installation on the upper part of the valve body

6 accumulator pistons and springs - accumulator pistons: 6

-Matching springs: Replace 6 aging clutch accumulator pistons and springs to improve shift buffering performance and reduce impact

5 specifications of sealing rings for 7 solenoid valves (including spare):

-12 × 2mm: 4 pieces (1 spare)

-13.5 × 2mm: 4 pieces (1 spare)

-11 × 1.5mm: 8 pieces (2 spare)

-15.60 × 1.78mm: 1 piece

-12.95 × 1.69mm: 1 sealing requirement for different types of solenoid valves (such as SSA, SSB, SSE) to prevent oil leakage from the solenoid valve

8 Vacuum Testing Tools - Test Spring: 1 piece

-Test plug: 1 for vacuum testing after valve body repair, to check the sealing of the oil passage and the flexibility of valve action

Note: Some packaging pockets are designed for multiple models and may indicate other application information. Please refer to the "Installation Guide" in the kit for accuracy.

Key technical characteristics and installation requirements

(1) Technical adaptability

Accurate size matching

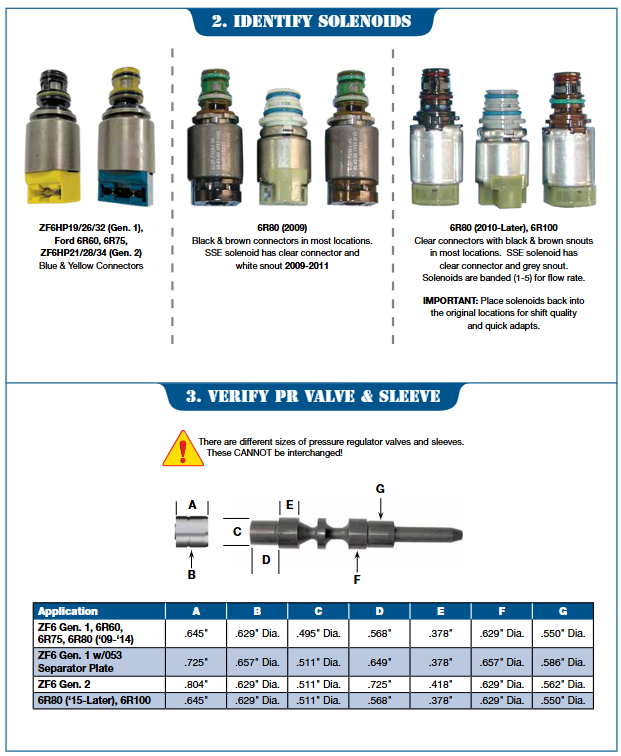

The kit components strictly follow the original specifications of the Ford 6R80/6R100 valve body, such as a pressure regulator sleeve diameter of. 629 "and length of. 645", which are perfectly compatible with the original valve (diameter of. 645 ", critical mating surface of. 511") to avoid pressure control failure caused by dimensional deviations. Special attention should be paid: the pressure regulator valve and sleeve cannot be interchanged across different models. Before installation, the dimensions must be confirmed with a caliper (refer to the table below):

Application model key dimensions (A: length/B: diameter/C: diameter)

6R80 (after 2015)/6R100 A=. 645 ", B=. 629", C=. 511“

ZF6 Gen1 (including 6R80 2009-2014) A=. 645 ", B=. 629", C=. 495“

ZF6 Gen2 A=.804",B=.629",C=.511"

Material reinforcement design

The core components (such as accumulator piston and seal ring) are made of Sonnax special wear-resistant materials: the piston is made of high-strength engineering plastics, which is oil resistant and anti-aging; The sealing ring is made of nitrile rubber or fluororubber material, suitable for transmission oil (Ford XT-6-QSP/Merck SP), and is not easily hardened or deformed after long-term use.

(2) Key installation requirements

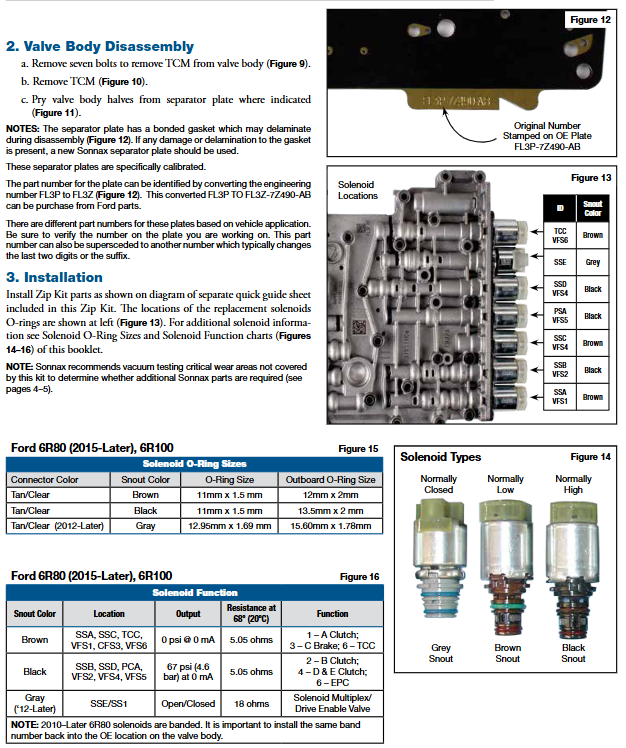

Valve body model identification

Before installation, it is necessary to confirm the compatibility of the valve body through the following 3 steps to avoid misuse:

Casting identification: The casting number for the upper valve body of 6R80 (after 2015) is 9FL3P-7A092-BA/FL3P-7A092-AA, and the lower valve body is FL3P-7A101-AA, without D2 Passage Eliminated;

Electromagnetic valve identification: The electromagnetic valve connector is made of transparent material, and the nozzle color is black/brown (ordinary electromagnetic valve) or gray (SSE electromagnetic valve), and the surface of the electromagnetic valve has flow level markings (1-5);

Pressure regulator identification: The pressure regulator sleeve has a dedicated groove (refer to product figure 4), and the size should be consistent with the specifications of 6R80/6R100 in the table.

Installation specifications

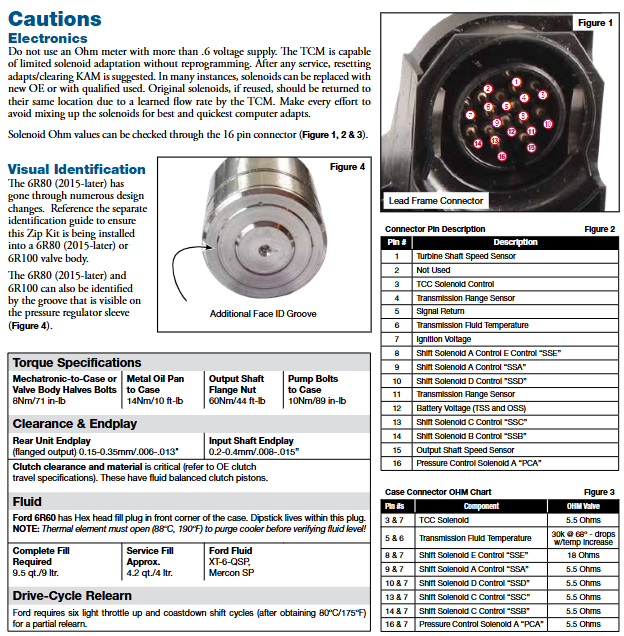

Torque requirements: The connecting bolts between the valve body and the gearbox housing have a torque of 8Nm (71 in lb), the metal oil pan bolts have a torque of 14Nm (10 ft lb), and the output shaft flange nuts have a torque of 60Nm (44 ft lb). A torque wrench is required to ensure accuracy;

Installation of solenoid valve: If the old solenoid valve is reused, it needs to be installed back to its original position (TCM has learned its flow characteristics) and cannot be confused; The new solenoid valve needs to correspond to the "nozzle color position" (e.g. brown nozzle corresponds to SSA/SSC/TCC solenoid valve);

Vacuum testing: After installation, the built-in test spring and end plug of the kit must be used for vacuum testing to check the sealing of the oil passage (qualification standard: stable vacuum degree, no obvious leakage), otherwise it may cause the fault to recur after maintenance.

Postoperative calibration

After the repair is completed, it is necessary to reset the adaptive learning value (KAM) of the transmission. It is recommended to use a Ford specific diagnostic tool to perform this;

Complete 6 cycles of light throttle up and down shifting (after the oil temperature reaches 80 ℃) to allow TCM to relearn shifting parameters and ensure shifting quality;

The transmission fluid needs to be filled with Ford original XT-6-QSP or Mercon SP specifications, with a full filling of 9.5 quarts (9 liters) and maintenance filling of 4.2 quarts (4 liters). The oil level should be checked after the temperature reaches 88 ℃ (190 ℉) and the thermal control valve opens.

Fault diagnosis and additional repair suggestions

(1) Typical faults and kit compatibility

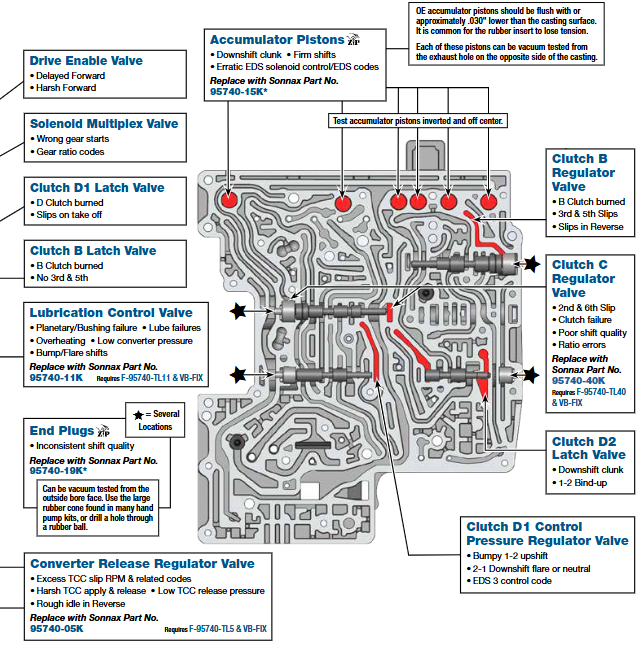

The kit can specifically solve the following faults of 6R80/6R100. If the fault exceeds the scope, additional specialized components need to be purchased:

Additional suggestions on the ability to solve typical fault kits

Shift shock/jerking can be solved (replace accumulator piston, pressure regulator). If the fault still exists, check the clutch clearance (must comply with OE specification 0.2-0.4mm)

Shift delay/no reverse gear can be solved (replace end plugs, sealing rings, repair oil passage leaks). Check the transmission oil pump pressure (must comply with 10Nm pump bolt torque)

The fault code of solenoid valve (such as P0868 low pressure) can be solved by replacing the sealing ring and pressure regulator of the solenoid valve. Use an ohmmeter to check the resistance of the solenoid valve (SSA/SSB=5.5 Ω, SSE=18 Ω)

TCC slip/lock abnormality can be resolved (replace TCC related sealing rings, bypass clutch adjuster). Check the wear of the torque converter and replace it if necessary

(2) Key wear areas and testing

The technical manual accompanying the kit specifies in detail the wear areas of the valve body that need to be inspected in detail. It is recommended to verify through vacuum testing:

Lower valve body: main pressure regulator valve, clutch A/E control regulator valve, solenoid valve pressure regulator valve. If the vacuum degree is insufficient (such as below 50% of the standard value), an additional Sonnax oversize valve kit (such as 95740-46K main pressure valve kit) needs to be purchased;

Upper valve body: accumulator piston (sealing in inverted state needs to be tested), clutch B/D control valve. If the piston sinks more than 0.030 ", the reinforced piston needs to be replaced (the kit includes the basic version, and the high-strength version needs to be ordered separately).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923