+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

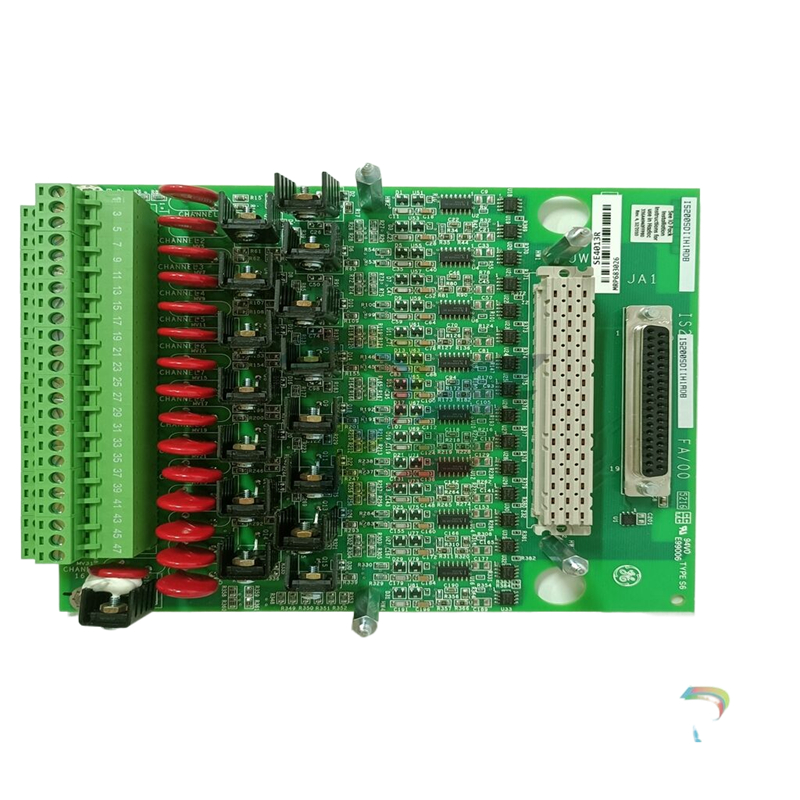

GE 8206-TI-IS 8-channel Intrinsically Safe RTD input

GE 8206-TI-IS 8-channel Intrinsically Safe RTD input

GE 8206-TI-IS 8-channel Intrinsically Safe RTD input

Counter alarms

• Preset value reached

CONTROL DATA (WRITE ONLY)

Counter preset value

• 32 bit signed

• Load preset value = 0 to disable

Counter commands

• Start / stop / reset

NOTE: Channel 1 counter can also be controlled by control gate

input: 1= start (count), 0 = pause

ISOLATION

Any channel to Railbus

• 100 V ac

Between input channels

• None (common 0 V connection)

Between output channels

• 30 V ac

RESPONSE TIMES

Signal change to availability on Railbus

• 25 ms (max.)

POWER SUPPLIES

Railbus current (both channels @22 mA)

• 300 mA (max.)

Bussed field power

• 20 mA @ 24 ± 10% V dc

Power dissipation (both channels @22 mA)

• 2.8 W (max.)

• No load – 2.0 W (max.)

MECHANICAL

Module Key Code

• F2

Module width

• 42 mm

Weight

• 260 g

SAFETY

Field wiring protection

• Non-incendive

FM and ATEX Cat 3 NON-INCENDIVE

FIELD WIRING PARAMETERS

The following figures are for Gas Groups A/B (IIC)

unless otherwise stated.

Current inputs (Ch1 & Ch2)

• Uo ≤ 0.6 V, Io ≤ 0.5 mA, Po ≤ 75 μW

• Ca = 1000 μF, La = 1000 mH

3-wire current inputs (Ch1 & Ch2)

• Uo 30 V, Io ≤ 102.5 mA, Po ≤ 765.7 mW

• Ca = 0.165 μF, La = 6 mH, La/Ra = 82 μH/Ω

Voltage inputs (Ch1 & Ch2)

• Uo ≤ 5.5 V, Io ≤ 0.58 mA, Po ≤ 0.8 mW

• Ca = 535 μF, La = 1000 mH

3-wire voltage inputs (Ch1 & Ch2)

• Uo ≤ 30 V, Io ≤ 102.6 mA, Po ≤ 765.8 mW

• Ca = 0.165 μF, La = 6 mH, La/Ra = 82.1 μH/Ω

NAMUR inputs (Ch1 & Ch2)

• Uo ≤ 9.1 V, Io ≤ 10.6 mA, Po ≤ 24 mW

• Ca = 20 μF, La = 490 mH

NAMUR gate input (Ch1)

• Uo ≤ 9.1 V, Io ≤ 10.6 mA, Po ≤ 24 mW

• Ca = 20 μF, La = 490 mH

Discrete outputs (Ch1 & Ch2)

Each pair of field terminals may be considered as nonincendive when connected into a field circuit with the

following parameters

• Vmax=30 Vdc, Imax=100 mA, Ci

=0 μF, Li

=0 mH

8127-DI-SE

• 32 channel module, configurable

channel by channel as DI, SOE or both

• Switch or Proximity Detector Inputs

• Captures events with 1/4 ms resolution

• Distributed architecture provides

accurate event recording

• Line fault detection on all inputs

(switch inputs need resistors)

• 24 Vdc bussed field power required

• Module provides power to all field

inputs, simplifying field wiring

• High time stamp resolution for more

accurate event sequencing

• Log data from other events, including

controller status and module alarms

• Export data to PC applications for

reporting or further analysis

32 Channel Sequence of Events 8127-DI-SE

Non-Isolated, Module-Powered

Sequence of Events (SOE recording is

needed to capture both the first event

and the sequence of a number of events

that occurred during a shut-down or trip

sequence in order to better understand the

cause of the event. When this occurs, events

can take place very rapidly throughout

your process area. The SOE Modules and

companion Event Logger Software provide

a means of recording these events and use

highly accurate time stamps to determine

the precise order in which they occurred.

8127-DI-SE is a 32-channel SOE module whose

primary focus is to monitor the status of digital

inputs and record state changes to an internal

buffer. The state changes are timestamped to

the nearest 1/4 millisecond. Once recorded the

states the state data is periodically transferred

to the controller. Each module has a buffer size

of 512 events which the controller can empty

in about 500 ms, capturing approximately

1000 events per second.

SOE Event Logger Software

SOE event logger software is provided with

all PAC8000 Workbench products. The event

logger software collects time stamped data

from the controller, merges information from

multiple controllers into a chronological

journal and exports the data to standard

event viewers. Other data export options

include OPC Event format or a basic text file.

The event logging software can also be used

to record other events in addition to SOE

activity. For example, it could be used to

record changes of state in the controller, such

as when control switches between redundant

controllers. It could be used to record when

an analog limit has been exceeded or when

a digital module changes state. This powerful

capability enables you to record all the

critical events in your process, providing you

with a complete picture for further analysis.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

91

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923