K-WANG

Rockwell Automation 836T Series Differential Pressure Controller

Protection ability: It can resist oil/water flow erosion, prevent cotton wool and dust from entering the shell, and is suitable for scenarios that require environmental sealing.

Rockwell Automation 836T Series Differential Pressure Controller

Product Core Description

1. Basic specifications and applicable scenarios

Model classification: Bulletin 836T, including three types: Type 1, 4, and 13, all designed to be oil tight.

Protection ability: It can resist oil/water flow erosion, prevent cotton wool and dust from entering the shell, and is suitable for scenarios that require environmental sealing.

Connection specifications: The pressure interface is 1/4 "-18 N.P.T.F (American dry sealed cone pipe thread), and the electrical interface includes 1/2" -14 N.P.T (optional Pg 13.5 BS20 specification).

Bellows material: provides two options, each suitable for different media——

Copper alloy corrugated pipe: suitable for water, air, and non corrosive liquids/gases;

316 stainless steel corrugated pipe: suitable for liquids/gases with stronger corrosiveness.

2. Core Structure and Function

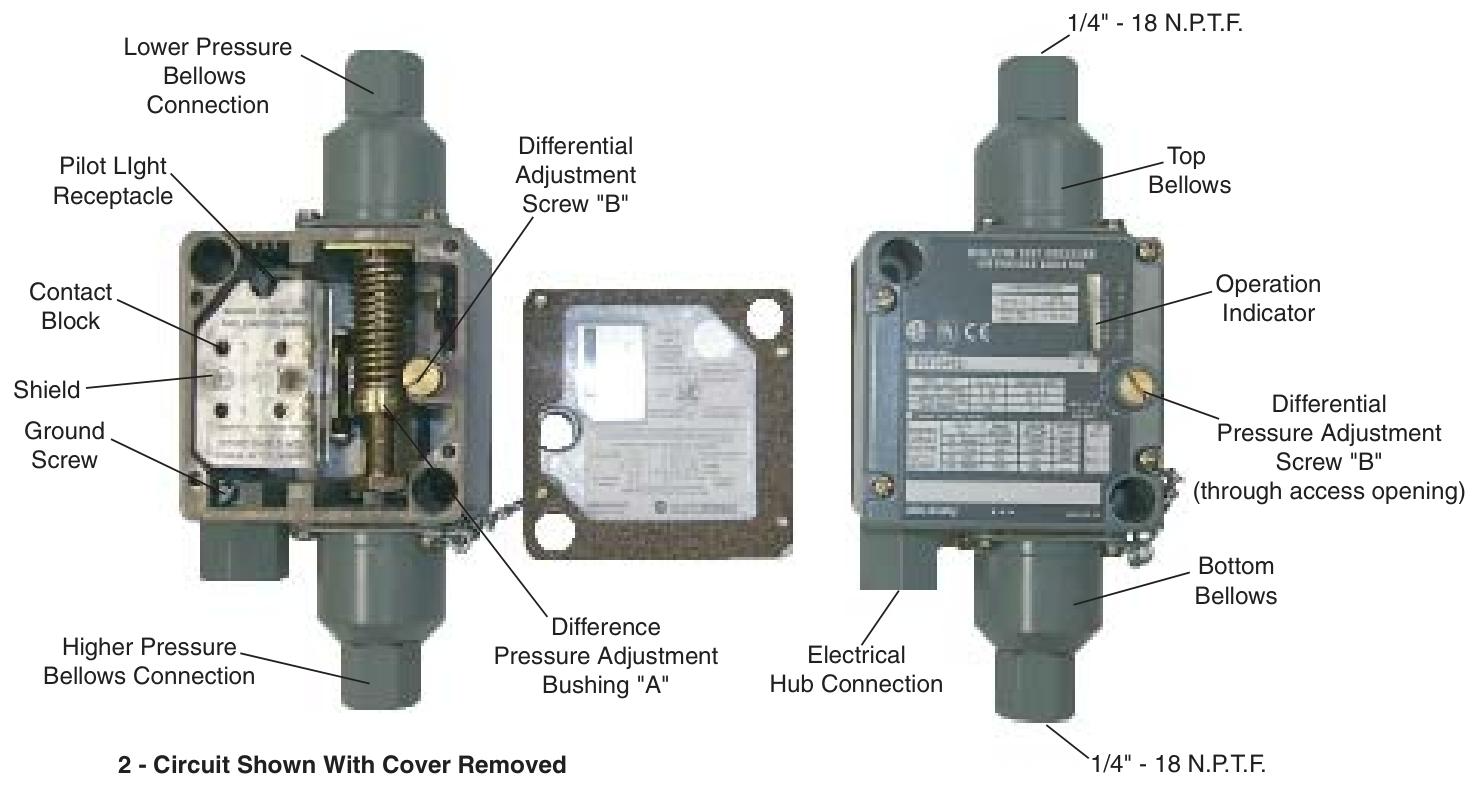

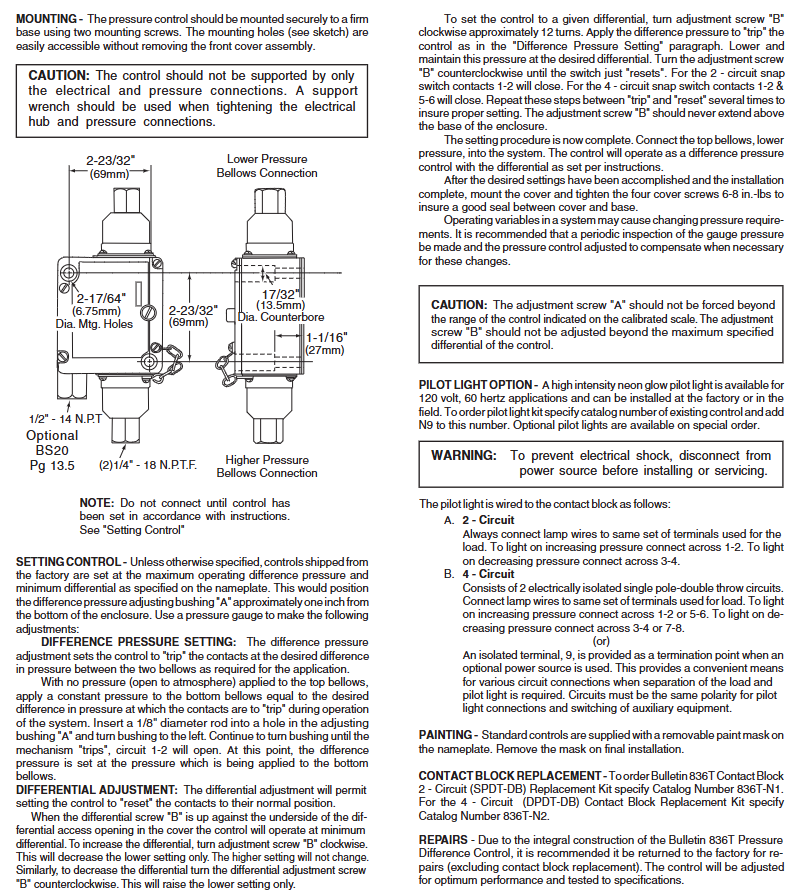

Core components: including Top Bellows, Bottom Bellows (mechanical linkage), Contact Block, Adjustment Differential Screw "B", Pressure Adjustment Difference Bushing "A", Operation Indicator, optional Pilot Light, etc.

Pressure sensing principle: The action is triggered by the pressure difference between two corrugated tubes, regardless of the actual gauge pressure of the system; Adjustable "trip pressure" and "reset pressure", with the difference between the two being the "differential control pressure".

Contact module configuration: provides two specifications to meet different circuit requirements——

Contact module type Contact configuration Circuit function

2-circuit: 1 set of normally open (NO)+1 set of normally closed (NC) supports single pole double throw (SPDT) or independent circuit operation with the same polarity

4-circuit with 2 sets of normally open (NO) and 2 sets of normally closed (NC) supports double pole double throw (DPDT) or two sets of electrically isolated single pole double throw circuits, including isolated terminal 9, which can be connected to external power supply

Working principle

The controller responds to pressure difference changes through a "trigger reset" cycle, with the following specific logic:

1. Trigger (Trip) action (contact switching)

When any of the following conditions are met, the contact module switches states:

The pressure of the bottom corrugated pipe is higher than the preset trigger pressure difference of the top corrugated pipe;

The pressure of the bottom corrugated tube is constant, and the pressure of the top corrugated tube decreases by the preset trigger pressure difference.

2-channel circuit: normally closed circuit (1-2) is open, normally open circuit (3-4) is closed;

4-channel circuit: Two sets of normally closed circuits (1-2, 5-6) are disconnected, and two sets of normally open circuits (3-4, 7-8) are closed.

2. Reset action (contact recovery)

When any of the following conditions are met, the contact returns to its initial state:

The pressure of the bottom corrugated pipe is lower than that of the top corrugated pipe;

The pressure of the bottom corrugated pipe remains constant, while the pressure of the top corrugated pipe increases.

2-channel circuit: normally closed circuit (1-2) is closed, normally open circuit (3-4) is open;

4-channel circuit: Two sets of normally closed circuits (1-2, 5-6) are closed, and two sets of normally open circuits (3-4, 7-8) are disconnected.

3. Key definitions

Trip Pressure: The minimum pressure difference required to trigger contact switching;

Reset Pressure: The maximum pressure difference that triggers contact recovery;

Differential control: The difference between the trigger pressure and the reset pressure can be independently adjusted.

Installation requirements

1. Mechanical installation

Fixing method: It needs to be fixed on a stable base with two screws, and the installation hole specification is "2-17/64" diameter (6.75mm)+2-23/32 "countersunk hole (69mm)", which can be operated without disassembling the front cover;

Prohibited operation: Do not support the controller solely through electrical or pressure interfaces; When tightening the electrical and pressure interfaces, a support wrench should be used to avoid damaging the components.

2. Precautions for Pre Installation

Before installation, it is necessary to complete the parameter settings ("Setting Control" steps) according to the instructions, otherwise the system cannot be connected;

The pressure interface distinguishes between the "Lower Pressure Bellows Connection" and the "Higher Pressure Bellows Connection", which need to be connected to the corresponding system.

Parameter setting steps

The factory default setting is "maximum trigger pressure difference+minimum control pressure difference" (adjusting the sleeve "A" about 1 inch from the bottom of the housing), which requires the assistance of a pressure gauge for calibration. It is divided into two steps:

1. Trigger the Difference Pressure Setting

The top corrugated pipe is vented to the atmosphere (without pressure), and a constant pressure is applied to the bottom corrugated pipe to trigger the target pressure difference;

Insert a 1/8 "diameter rod into the hole of the adjusting sleeve" A ", rotate the sleeve to the left until the controller" triggers "(circuit 1-2 is disconnected, circuit 1-2 and 5-6 are disconnected);

At this point, the pressure of the bottom corrugated tube is the set trigger pressure difference.

2. Differential Adjustment Control

Adjustment logic: Adjusting screw "B" only changes the reset pressure difference (does not affect the triggering pressure difference) - turn screw "B" clockwise → increase the control pressure difference (reset pressure difference decreases); Turn counterclockwise → reduce the control pressure difference (reset pressure difference increases); When screw "B" is tightened against the bottom of the front cover, control the pressure difference to be minimized.

Specific steps:

Rotate screw "B" clockwise for about 12 turns;

Apply pressure according to the "trigger pressure difference setting" steps to trigger the controller, then reduce the pressure to the target control pressure difference and maintain it;

Rotate screw "B" counterclockwise until the controller is "reset" (2 circuits 1-2 are closed, 4 circuits 1-2, 5-6 are closed);

Repeat the "trigger reset" cycle several times to ensure stable settings;

Screw "B" should not protrude from the bottom of the housing, and adjusting sleeve "A" should not exceed the control range marked on the dial.

3. Complete the setup

After parameter calibration, connect the top corrugated pipe (low pressure end) to the system, install the front cover and tighten 4 screws (torque 6-8 inch pounds) to ensure sealing. It is recommended to regularly check the system pressure and recalibrate as needed.

Optional accessories and maintenance

1. Pilot Light Options

Specification: High brightness neon lamp, suitable for 120V, 60Hz scenes, can be pre installed in the factory or installed on site;

Ordering method: Add "N9" (such as 836T-XXX-N9) after the existing controller model, special specifications require customization;

Wiring rules:

2-channel circuit: Connect the light wire to the load terminal, connect 1-2 for "on when pressure rises" and 3-4 for "on when pressure drops";

4-channel circuit: Connect the light wire to the load terminal (1-2/5-6 or 3-4/7-8), or connect it to an external power source through isolation terminal 9 (ensuring the same polarity of the circuit);

Safety reminder: Disconnect the power supply before installation/maintenance to prevent electric shock.

2. Component replacement and maintenance

Contact module replacement: 2-channel module replacement kit model 836T-N1, 4-channel module kit model 836T-N2;

Overall maintenance: As the controller is an integrated structure, it is recommended to return all faults except for the contact module to the factory for repair (the factory will calibrate to the best performance and test according to specifications);

Nameplate protection: The standard controller nameplate comes with a removable protective film, which needs to be removed during final installation.

Safety and Compliance

CE certification: The product complies with CE standards;

Operation warning: Adjust the components within the marked range to avoid mechanical damage; Corrosive media should use 316 stainless steel corrugated pipes to prevent material failure;

WEEE and Environmental Protection: The document does not mention specific environmental compliance information, please refer to Rockwell Automation's General Environmental Policy.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923