K-WANG

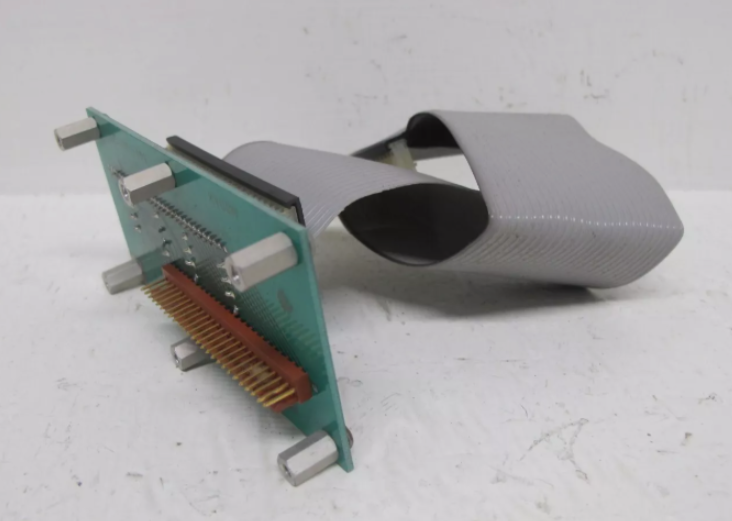

Xycom 96574-001 module circuit board 96529-001 8503 PCB PWA programmable

Xycom 96574-001 module circuit board 96529-001 8503 PCB PWA programmable

Product Overview

The 96574-001 module circuit board of Xycom and its related 96529-001 and 8503 PCB PWA programmable circuit boards are key components used for various control, monitoring, and data processing tasks in the field of industrial automation. These circuit boards, with their advanced design and reliable performance, are widely used in various complex industrial environments, providing strong support for the stable operation and efficient control of industrial systems.

Specification parameters

96574-001 module: Although comprehensive and detailed official specifications have not yet been obtained, it is speculated from its application scenarios that it may have multiple interface types for connecting other devices to achieve data exchange, and can operate stably within a specific voltage range (such as common industrial 24V DC voltage) to adapt to the power supply conditions of industrial sites.

96529-001: Although the specific parameters are not fully clear, there is a high probability of compatibility design with 96574-001 in terms of electrical characteristics, size specifications, etc. For example, it may have matching installation holes for joint installation in the equipment, and cooperate with 96574-001 in signal processing capabilities, such as having certain signal amplification and conversion capabilities to meet the signal requirements of the overall system.

8503 PCB PWA Programmable: As a programmable circuit board, it may support multiple programming languages or protocols for functional customization. From common similar products, it can be inferred that it may have storage units of a certain capacity (ranging from tens of KB to several MB) for storing programs and data, as well as high-speed data processing capabilities that can respond to and process external input instructions and data in a short period of time.

Core functions

96574-001 module: The main functions may focus on data acquisition and preliminary processing, such as collecting analog or digital signals from sensors and other devices, and performing simple preprocessing operations such as filtering and amplification on these signals. Then, the processed data is transmitted to other core components in the system for further analysis and decision-making.

96529-001: It is highly likely to be responsible for the execution of specific functions, such as in an automated production line control system, it may specifically control the action of a certain actuator, such as controlling the start stop, forward and reverse rotation, and speed adjustment of motors, to ensure the orderly operation of the production line.

8503 PCB PWA Programmable: With its programmable features, it can flexibly configure the control logic of the system. Users can set the flow of data, processing methods, and collaborative working modes between devices through programming according to actual application needs, greatly improving the adaptability and scalability of the system.

Working principle

96574-001 module: When external sensors or other devices transmit signals, the input interface on the module introduces the signals. Subsequently, the internal circuit processes the signal according to the preset logic, such as converting the analog signal to a digital signal through an analog-to-digital conversion circuit, amplifying and filtering the signal using components such as operational amplifiers, and finally transmitting the processed signal to subsequent modules through an output interface.

96529-001: This circuit board receives control instructions from other modules (such as 96574-001 module or system controller), which are transmitted to the internal control chip through the interface circuit. The control chip controls the connected actuator through the driving circuit based on the instruction content, such as sending control signals to the motor driver to achieve precise control of the motor and other equipment.

8503 PCB PWA Programmable: Users download the pre written program to the storage unit of the circuit board through programming software. When the system is running, the circuit board reads the program from the storage unit and processes the input data according to the logic set by the program. For example, based on input temperature, pressure, and other data, through algorithmic calculations in the program, corresponding control signals are output to the executing device to maintain the stable operation of the system.

Key advantages

High reliability: Designed and manufactured according to industrial standards, it can operate stably for a long time in harsh industrial environments such as high temperature, humidity, and strong electromagnetic interference, reducing equipment downtime and ensuring the continuity of industrial production.

Flexibility: The programmable features of the 8503 PCB PWA and the collaborative working mode between various circuit boards enable the entire system to be flexibly configured and adjusted according to different application scenarios and requirements, meeting diverse industrial control needs.

Strong compatibility: These circuit board cards from Xycom often have good compatibility and can be connected and communicated with various brands and models of industrial equipment, making them easy to integrate into existing complex industrial systems and reducing the difficulty of system upgrades and renovations.

Precautions

Installation environment: It is necessary to install the circuit board in a dry, well ventilated, and suitable temperature environment, avoiding installation in places with a large amount of dust, water vapor, or corrosive gases to prevent damage to the circuit board due to environmental factors.

Static electricity protection: When installing and maintaining circuit boards, operators need to wear protective equipment such as anti-static wristbands to avoid damage to precision electronic components on the circuit board caused by human static electricity.

Programming specifications: For the 8503 PCB PWA programmable circuit board, the programming process must strictly follow the programming specifications and manual requirements to ensure the accuracy and stability of the program and avoid system failures caused by programming errors.

Similar model supplement

Xycom XVME-560: This is a VMEbus PCB circuit board commonly used for data acquisition and processing tasks, playing an important role in industrial automation control systems with high data transmission rates and processing capabilities.

Xycom 82029 BC 82027-001-E: A PCB circuit board product belonging to Xycom, which may have similarities with 96574-001 in certain specific functions or application scenarios, such as signal processing, equipment control, etc., and can be used as an alternative in some scenarios.

Xycom 96574-001 module circuit board 96529-001 8503 PCB PWA programmable

Product Overview

The 96574-001 module circuit board of Xycom and its related 96529-001 and 8503 PCB PWA programmable circuit boards are key components used for various control, monitoring, and data processing tasks in the field of industrial automation. These circuit boards, with their advanced design and reliable performance, are widely used in various complex industrial environments, providing strong support for the stable operation and efficient control of industrial systems.

Brand background

Xycom is renowned in the field of industrial automation and has long been committed to providing high-quality industrial computers, control modules, and related solutions to global customers. Over the years, through continuous technological innovation and product optimization, Xycom has established a good reputation in multiple industries such as automation, aerospace, and manufacturing. Its products are known for their excellent reliability, powerful functionality, and outstanding compatibility, and are a trusted brand by many industrial enterprises.

Specification parameters

96574-001 module: Although comprehensive and detailed official specifications have not yet been obtained, it is speculated from its application scenarios that it may have multiple interface types for connecting other devices to achieve data exchange, and can operate stably within a specific voltage range (such as common industrial 24V DC voltage) to adapt to the power supply conditions of industrial sites.

96529-001: Although the specific parameters are not fully clear, there is a high probability of compatibility design with 96574-001 in terms of electrical characteristics, size specifications, etc. For example, it may have matching installation holes for joint installation in the equipment, and cooperate with 96574-001 in signal processing capabilities, such as having certain signal amplification and conversion capabilities to meet the signal requirements of the overall system.

8503 PCB PWA Programmable: As a programmable circuit board, it may support multiple programming languages or protocols for functional customization. From common similar products, it can be inferred that it may have storage units of a certain capacity (ranging from tens of KB to several MB) for storing programs and data, as well as high-speed data processing capabilities that can respond to and process external input instructions and data in a short period of time.

Core functions

96574-001 module: The main functions may focus on data acquisition and preliminary processing, such as collecting analog or digital signals from sensors and other devices, and performing simple preprocessing operations such as filtering and amplification on these signals. Then, the processed data is transmitted to other core components in the system for further analysis and decision-making.

96529-001: It is highly likely to be responsible for the execution of specific functions, such as in an automated production line control system, it may specifically control the action of a certain actuator, such as controlling the start stop, forward and reverse rotation, and speed adjustment of motors, to ensure the orderly operation of the production line.

8503 PCB PWA Programmable: With its programmable features, it can flexibly configure the control logic of the system. Users can set the flow of data, processing methods, and collaborative working modes between devices through programming according to actual application needs, greatly improving the adaptability and scalability of the system.

Working principle

96574-001 module: When external sensors or other devices transmit signals, the input interface on the module introduces the signals. Subsequently, the internal circuit processes the signal according to the preset logic, such as converting the analog signal to a digital signal through an analog-to-digital conversion circuit, amplifying and filtering the signal using components such as operational amplifiers, and finally transmitting the processed signal to subsequent modules through an output interface.

96529-001: This circuit board receives control instructions from other modules (such as 96574-001 module or system controller), which are transmitted to the internal control chip through the interface circuit. The control chip controls the connected actuator through the driving circuit based on the instruction content, such as sending control signals to the motor driver to achieve precise control of the motor and other equipment.

8503 PCB PWA Programmable: Users download the pre written program to the storage unit of the circuit board through programming software. When the system is running, the circuit board reads the program from the storage unit and processes the input data according to the logic set by the program. For example, based on input temperature, pressure, and other data, through algorithmic calculations in the program, corresponding control signals are output to the executing device to maintain the stable operation of the system.

Key advantages

High reliability: Designed and manufactured according to industrial standards, it can operate stably for a long time in harsh industrial environments such as high temperature, humidity, and strong electromagnetic interference, reducing equipment downtime and ensuring the continuity of industrial production.

Flexibility: The programmable features of the 8503 PCB PWA and the collaborative working mode between various circuit boards enable the entire system to be flexibly configured and adjusted according to different application scenarios and requirements, meeting diverse industrial control needs.

Strong compatibility: These circuit board cards from Xycom often have good compatibility and can be connected and communicated with various brands and models of industrial equipment, making them easy to integrate into existing complex industrial systems and reducing the difficulty of system upgrades and renovations.

Precautions

Installation environment: It is necessary to install the circuit board in a dry, well ventilated, and suitable temperature environment, avoiding installation in places with a large amount of dust, water vapor, or corrosive gases to prevent damage to the circuit board due to environmental factors.

Static electricity protection: When installing and maintaining circuit boards, operators need to wear protective equipment such as anti-static wristbands to avoid damage to precision electronic components on the circuit board caused by human static electricity.

Programming specifications: For the 8503 PCB PWA programmable circuit board, the programming process must strictly follow the programming specifications and manual requirements to ensure the accuracy and stability of the program and avoid system failures caused by programming errors.

Similar model supplement

Xycom XVME-560: This is a VMEbus PCB circuit board commonly used for data acquisition and processing tasks, playing an important role in industrial automation control systems with high data transmission rates and processing capabilities.

Xycom 82029 BC 82027-001-E: A PCB circuit board product belonging to Xycom, which may have similarities with 96574-001 in certain specific functions or application scenarios, such as signal processing, equipment control, etc., and can be used as an alternative in some scenarios.

Application scenarios

Industrial automation production line: used to control the operation of various equipment on the production line, such as controlling the movement of robots, the start stop and speed adjustment of conveyor belts, the workflow of processing equipment, etc., to achieve automation and intelligence of the production process.

Smart Factory: In smart factories, these circuit boards can be used for equipment status monitoring, data acquisition and analysis, and optimization control of production processes. For example, by collecting equipment operation data, analyzing the health status of the equipment, predicting faults in advance, and improving the production efficiency and product quality of the factory.

Energy management system: In the energy production and distribution system, it can be used to monitor and control the operation of energy equipment, such as power generation equipment, transmission equipment in the power system, refining equipment in the petrochemical industry, etc., to achieve efficient utilization and rational distribution of energy.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923