K-WANG

Bently 990 vibration transmitter

Bently 990 vibration transmitter

Product Overview

Core functions and applications

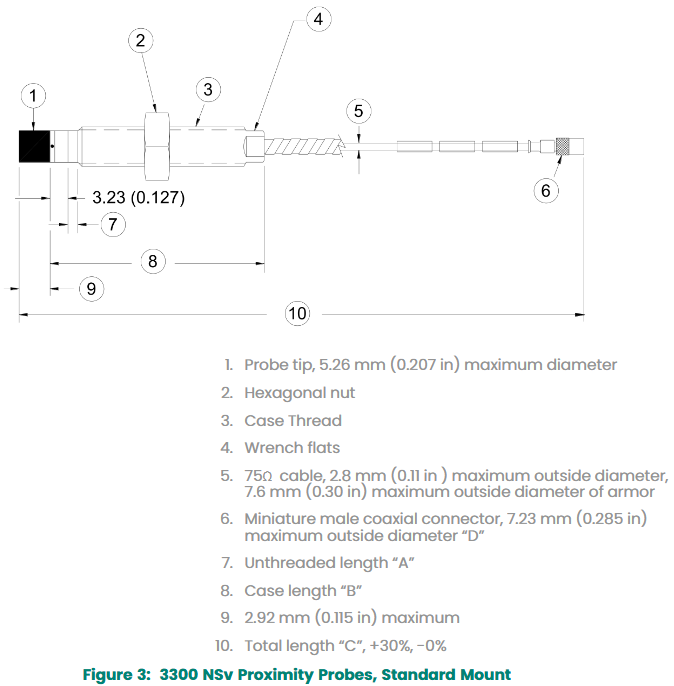

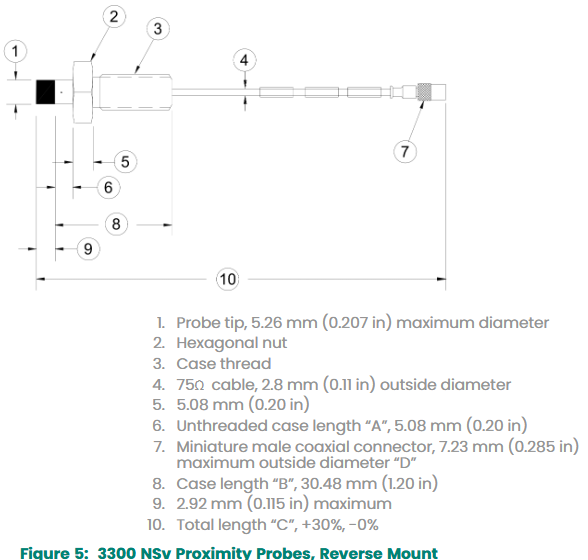

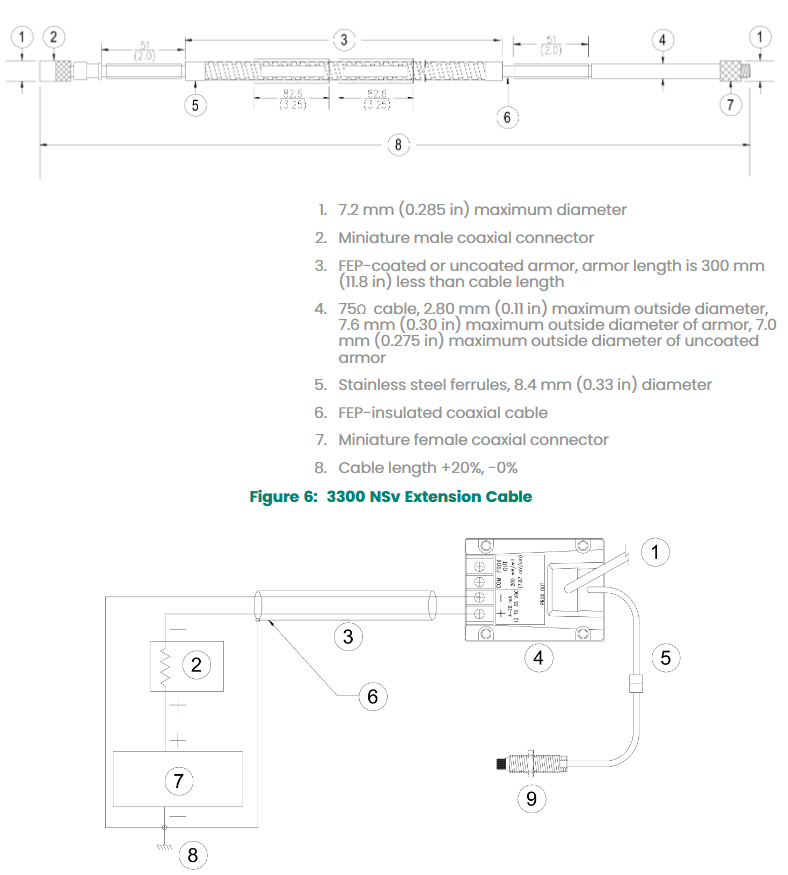

The 990 vibration transmitter is mainly aimed at original equipment manufacturers (OEMs) of centrifugal air compressors, small pumps, motors, or fans. It is used to convert vibration signals into 4-20 mA standard signals and input them into mechanical control systems. It receives input from 3300 NSv proximity probes and supporting extension cables (supporting 5-meter and 7-meter system lengths), processes the signal into engineering units of peak to peak vibration amplitude, and outputs a proportional 4-20 mA signal for mechanical protection alarm and logic control.

Main features

Integrated Proximitor sensor, no external unit required.

Provide non isolated "PROX OUT" and "COM" terminals and coaxial connectors to output dynamic vibration and gap voltage signals for diagnosis (requiring signal isolation with 990/991 test adapters).

Equipped with non interactive zero and range potentiometers, supporting circuit adjustment; The test input pin can quickly verify the circuit signal output through a function generator.

Equipped with a "Not OK/Signal Defeat" circuit to prevent high output or false alarms caused by probe failure or loose connections.

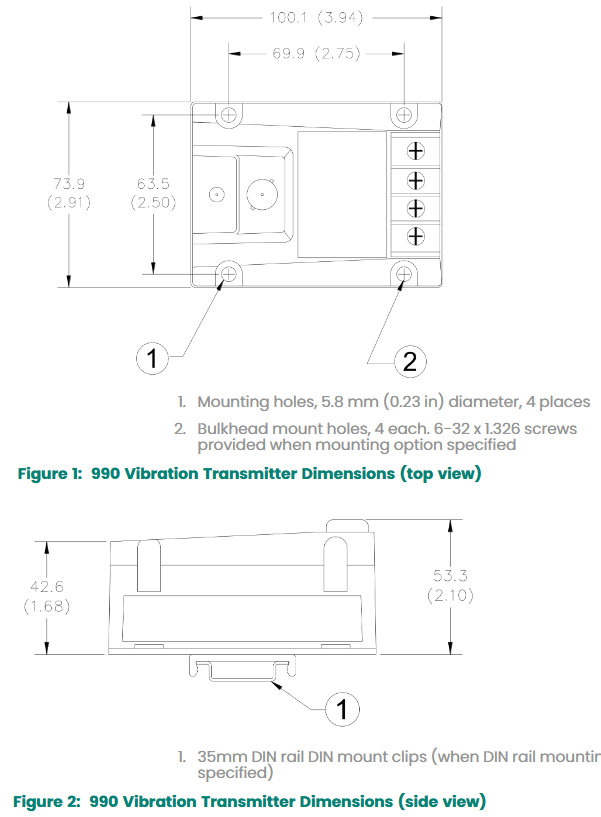

Supports DIN rail installation or through board installation (including standard accessories), suitable for high humidity (up to 100% condensation) environments.

Technical specifications

1. Electrical parameters

Startup suppression: After the power is turned on, the signal output remains in the<3.6 mA (NOT OK) state for 2-3 seconds, indicating that the device is not ready.

Proximitor sensor output: compatible with non grounded portable testing equipment; When using grounded AC power supply equipment, signal isolation must be achieved through the 122115-01 test adapter.

Output impedance: Prox Out is 10 k Ω, calibrated load is 10 M Ω.

Prox Out linear range: 1.4 mm (55 miles), starting at a distance of approximately 0.25 mm (10 miles) from the target surface.

Prox Out incremental scaling factor: 7.87 mV/µ m (200 mV/mil) ± 6.5% (typical value, including interchangeability error), worst-case scenario ± 10%; Typical noise level is 50 mV/pp.

Temperature stability: Within the range of 0 ° C to+70 ° C (+32 ° F to+158 ° F), the incremental scaling factor remains within ± 10% of 7.87 mV/µ m.

Frequency response: 5 Hz to 6000 Hz+0/-3 dB.

Minimum target size: 9.5 mm (0.375 inches) diameter.

Lead length: The maximum cable distance for the Proximitor sensor output (BNC connector) is 3 meters (10 feet).

Power supply: 28 V for hazardous areas (Zone 2 or Div 2).

2. Environmental and mechanical parameters

Temperature range:

Transmitter operating temperature: -35 ° C to+85 ° C (-31 ° F to+185 ° F); Storage temperature: -52 ° C to+100 ° C (-62 ° F to+212 ° F).

Probe operating and storage temperature: -52 ° C to+177 ° C (-62 ° F to+351 ° F).

Relative humidity: 100% condensing (non submerged, coaxial connectors need to be protected).

Mechanical characteristics:

Probe tip material: Polyphenylene sulfide (PPS); Shell material: AISI 303 or 304 stainless steel.

Probe cable: 75 Ω coaxial cable, FEP insulated; Optional armor (AISI 302 stainless steel with FEP outer sheath).

Tensile strength: The maximum tensile strength from the probe housing to the lead is 222 N (50 lbf).

Transmitter weight: 0.43 kg (0.9 lbm); Total system weight: Typical value 0.82 kg (1.8 lbm).

Compliance and Certification

1、 Basic compliance certification

FCC certification

The device complies with Part 15 of FCC regulations and must meet two conditions for operation:

Shall not cause harmful interference;

We must accept any interference received, including interference that may cause unexpected operations.

Electromagnetic Compatibility (EMC)

Compliant with EMC Directive 2014/30/EU;

Following standards:

EN 61000-6-2 (Immunity to industrial environments);

EN 61000-6-4 (Emission limits for industrial environments).

RoHS Directive

Compliant with RoHS Directive 2011/65/EU, restricting the use of specific hazardous substances (such as lead, mercury, etc.) in electronic and electrical equipment to meet environmental requirements.

Maritime certification

Compliant with ABS 2009 Steel Ship Rules (1-1-4/7.7, 4-8-3/1.11.1, 4-9-7/13), suitable for ship and offshore platform scenarios.

EPR label for Indian batteries

Certified by GE Oil&Gas India Private Limited, EPR certificate number: 1.1595372902047E+20, in compliance with relevant regulations on electronic waste management in India.

Hazardous Area Certification

1. ATEX certification

Compliant with ATEX Directive 2014/34/EU, the specific levels are as follows:

II 1 G Ex ia IIC T4 Ga: Suitable for Zone 0/1 hazardous areas, with an ambient temperature range of -35 ° C to+85 ° C.

II 3 G Ex nA IIC T4 Gc: Suitable for Zone 2 hazardous areas with an ambient temperature range of -35 ° C to+85 ° C.

2. IECEx certification

Consistent with ATEX certification level, suitable for international explosive environments, certification mark is:

Ex ia IIC T4 Ga(Zone 0/1);

Ex nA IIC T4 Gc(Zone 2)。

3. cNRTLus certification

Suitable for hazardous areas in North America, specific level:

Class I, Div 2, Groups A、B、C、D, Temperature rating T5@Ta +85 ° C (Type 4), to be installed according to drawing 128838.

Key parameters and precautions for certification

Entity parameters (hazardous area)

Terminal/connector Ui (voltage) Ii/Io (current) Pi/Po (power) Ci/Co (capacitor) Li/Lo (inductor)

Power terminal (E1-E2) 28 V 120 mA 0.84 W 20 nF 10 μ H

Proximitor terminals (E3-E4, J2) 28 V 6 mA 0.17 W 80 nF 1 H

Probe connector (J3) 28 V 100 mA 0.8 W 27.3 nF 5.3 mH

INSTALLATION REQUIREMENTS

When used in hazardous areas, cables (type A or B) that comply with EN 60079-25 standards must be used to ensure electrical connections meet explosion-proof requirements.

Grounding and shielding must strictly follow the manual specifications to avoid interference or safety hazards.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923