K-WANG

ABB AX400 series conductivity analyzer

ABB AX400 series conductivity analyzer

The ABB AX400 series conductivity analyzer is an industrial grade monitoring device that supports single/dual sensor inputs. It has three installation methods: wall mounted, pipeline mounted, and panel mounted. Its core function is to continuously monitor conductivity and support temperature automatic compensation (compatible with Pt100/Pt1000 sensors). The measurement range is 0~10000 µ S/cm, and the accuracy is better than ± 1% reading; The device is equipped with dual 5-digit LCD backlit display screens and a 5-key operation panel, supporting 4 analog output ranges (0-10mA/0-20mA/4-20mA, etc.), 3-5 relay outputs, and can be configured with 5-digit safety codes to protect parameters. It also provides functions such as sensor calibration, alarm settings, and fault diagnosis, and is widely used in industrial scenarios such as chemical, pharmaceutical, and water treatment.

Product Overview

Basic positioning

The ABB AX400 series is an industrial grade conductivity analyzer designed for continuous monitoring and control of fluid conductivity in industrial processes, supporting single or dual sensor inputs.

The equipment has automatic temperature compensation function, which can correct the measured value to the standard reference temperature of 25 ℃, ensuring data accuracy and suitable for complex industrial environments.

Core strengths

Multiple installation methods are compatible: wall mounted, pipeline mounted, and panel mounted to meet different site layout requirements.

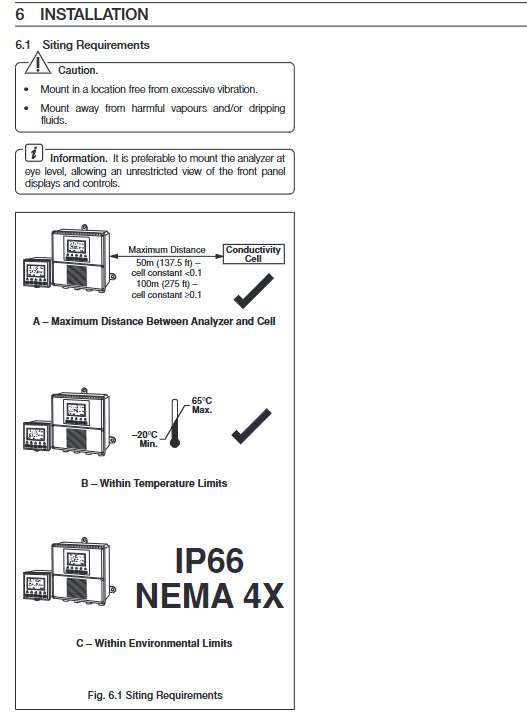

High protection and stability: protection level IP66/NEMA4X, working temperature -20~65 ℃, storage temperature -25~75 ℃, humidity ≤ 95% RH (no condensation).

Flexible output and alarm: supports analog signal retransmission, relay alarm, and can adapt to various industrial control systems.

Safe and convenient operation: Parameters are protected from accidental changes through a 5-digit security code, and the backlit display screen supports multilingual switching.

Core technical parameters

Category key parameter details

Conductivity measurement range: 0~0.5~10000 µ S/cm (supports multiple electrode constants)

Units µ S/cm, µ S/m, mS/cm, mS/m, M Ω· cm, TDS

Accuracy better than ± 1% reading

Temperature related compensation range -10~150 ℃ (14~302 ° F)

Programmable temperature coefficient of 0-5%/℃, supporting fixed curves such as HCl/NaCl/NH3

Sensor type Pt100/Pt1000 (programmable selection)

Output configuration analog output 2-channel standard (4-channel optional), isolated, supports 0-10mA/0-20mA/4-20mA

Relay output with 3 standard channels (5 optional), single pole double throw, contact capacity 5A/115/230V AC

Power supply and power consumption power input 85-265V AC 50/60Hz; Optional 12-30V DC/24V AC

Power consumption<10VA

Operation and Function Configuration

(1) Operation interface and buttons

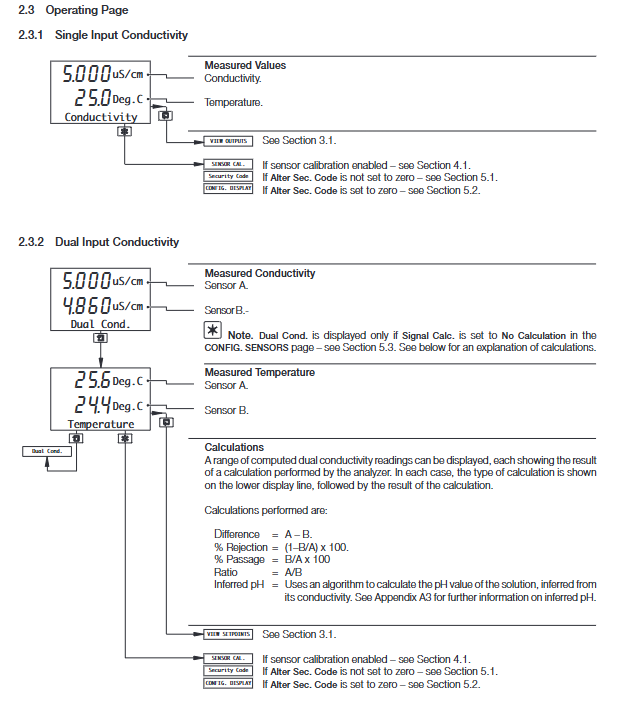

Display screen: Dual 5-digit 7-segment LCD (displaying measured values such as conductivity and temperature)+16 character dot matrix screen (displaying units and menu information), supporting backlight on/automatic mode.

Button function: 5 thin film buttons, which respectively realize menu switching, page scrolling, parameter adjustment, confirmation and saving operations.

(2) Core functional modules

sensor configuration

Supports single/dual sensors (Sensor A/B), with the ability to set conductivity units, electrode constants (0.01~10 cm ⁻¹), temperature compensation types, TDS coefficients (0.4~0.8), and units (ppm/mg/l/mg/kg).

In dual sensor mode, data calculation methods can be selected: difference (A-B), ratio (A/B),% pass rate (B/A × 100),% retention rate ((1-B/A) × 100), and derived pH (requiring NH3/NaOH temperature compensation).

Calibration function

You need to enable the 'Enable Cal.' permission and enter a 5-digit calibration code to perform calibration.

Calibration parameters: sensor slope (0.2000~5.000), sensor offset, temperature slope (0.2000~1.500), temperature offset (-40.0~40.0 ℃), support resetting to default values.

alarm configuration

Supports 3-5 alarm channels, with adjustable alarm types (off/alarm/status), associated parameters (conductivity/temperature or calculated values of sensors A/B), safe mode (Yes/No), action type (high/low), set value, hysteresis (0-5%), and delay time (0-60s).

Output configuration

Analog output can be assigned to measurement parameters or temperature, supporting linear/bilinear/2 decade logarithmic/3 decade logarithmic curves.

Fault default output: can be set to turn off/hold/drive to default value (0~22mA).

(3) Security protection

Parameter protection: Modifying the configuration requires entering a 5-digit security code (00000~19999) to prevent unauthorized operations.

Calibration protection: Calibration operation requires inputting a 5-digit calibration code to avoid incorrect calibration affecting accuracy.

Installation and maintenance

(1) Installation requirements

Installation environment: Keep away from excessive vibration, harmful vapors, and dripping liquids. It is recommended to install at a visual height for easy operation and observation.

Distance between electrode and analyzer: maximum 50m for electrode constant<0.1, maximum 100m for electrode constant ≥ 0.1.

Wiring specifications: The power supply must be grounded, and signal cables and power cables should be wired separately. It is recommended to use shielded twisted pair cables, with the shielding layer connected to the grounding column of the shell.

(2) Calibration and maintenance

Calibration preparation: A standard resistance box (0~10k Ω, accuracy ± 0.1%) and a digital milliampere meter (0~20mA) are required.

Calibration process: Disconnect the sensor → Connect the calibration device → Enter the calibration menu → Adjust slope/offset → Save parameters.

Daily maintenance: Regularly clean electrodes, check cable connections, and recalibrate if measurement deviations occur.

(3) Fault diagnosis

Possible causes and troubleshooting measures for fault phenomena

Display error code "FAULT TYPE 0001" sensor connection loose/electrode damaged. Check the sensor wiring and replace the electrode

Conductivity unresponsive, electrode contamination/incorrect parameter settings. Clean the electrode and verify the electrode constant and temperature compensation settings

Abnormal temperature reading. Temperature sensor malfunction/wiring error. Check Pt100/Pt1000 wiring and replace the sensor

Alarm does not trigger alarm setting value error/excessive hysteresis. Reset alarm parameters to reduce hysteresis

Applicable scenarios

Chemical industry: Monitor electrolyte solution concentration and changes in conductivity during reaction processes.

Pharmaceutical industry: Quality monitoring of purified water and water for injection (WFI).

Water treatment industry: reverse osmosis system, ion exchanger effluent monitoring.

Food and beverage industry: Control of solution concentration during production processes (such as saltwater and syrup).

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923