K-WANG

ABB ACH 400 AC Drive

ABB ACH 400 AC Drive

Safety instructions and basic information

Safety Warning: It is emphasized that equipment installation must be operated by qualified electricians. There is dangerous voltage present, and after disconnecting the power supply, it is necessary to wait for at least 5 minutes before opening the cover. The equipment is not repairable on site, and in case of malfunction, the factory or authorized service center should be contacted for replacement. Also mentioned are precautions such as automatic restart, parallel power supply of control terminals, and high temperature of heat sinks.

Installation related

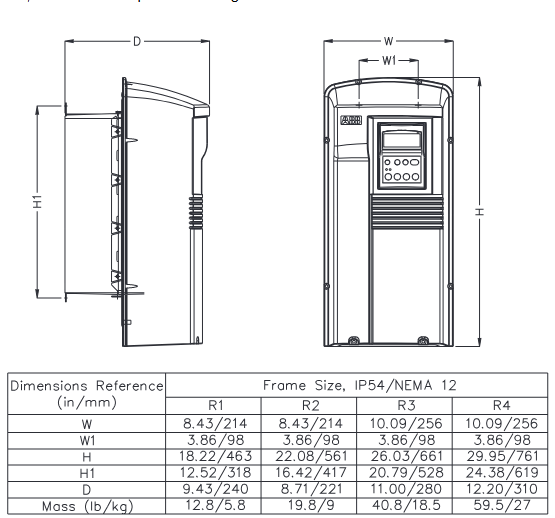

Preparation before installation: Tools such as screwdrivers and wire strippers should be prepared to record the power supply voltage, rated current, and other data on the motor nameplate. After unboxing, it includes a user manual, conduit box, warning stickers, and installation guide. The packaging box cover has a wall mounted template.

Installation environment: When using the station, the ambient temperature is 0-40 ° C (if the temperature reaches 50 ° C, the rated power and current need to be reduced to 90%), the installation altitude is 0-1000 meters (100% power), 1000-2000 meters (1% reduction per 100 meters), and the relative humidity is less than 95% (no condensation). It needs to be installed indoors in a controlled environment, with protection levels of IP21/NEMA Type 1 and IP54/NEMA Type 12, and IP54 protection against dust and light water spray. The storage and transportation temperature is -40-70 ° C.

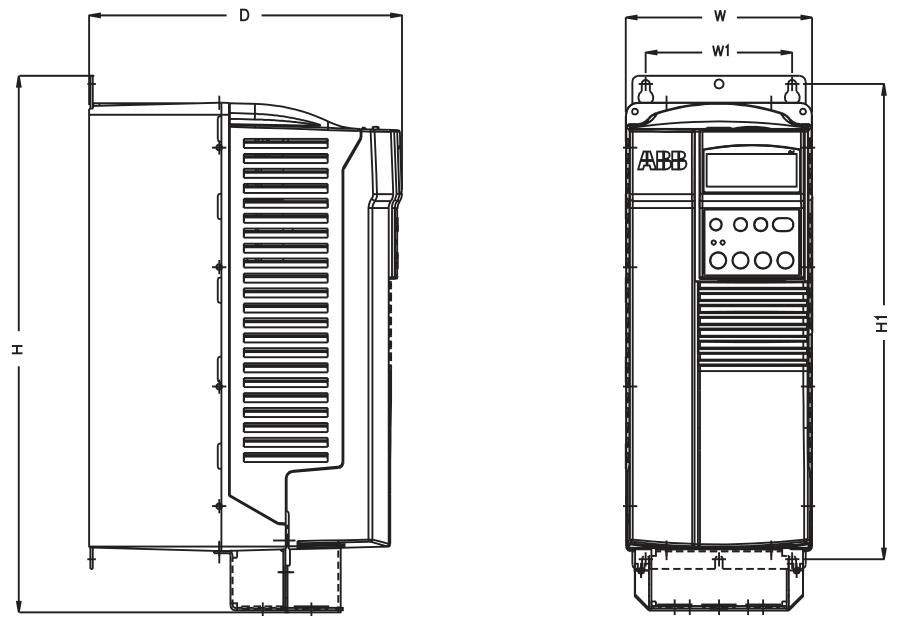

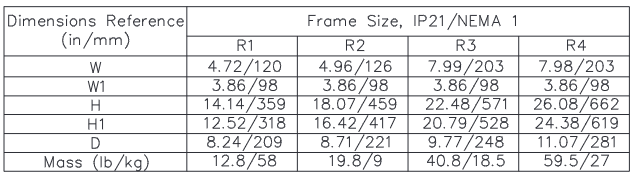

Size and Installation: Drivers with different protection levels and frame sizes have different sizes. The width, height, depth, and quality parameters of each frame size (R1-R4) for IP21/NEMA Type 1 and IP54/NEMA Type 12&4 are clearly defined. The installation needs to be vertically fixed on a smooth and sturdy surface, ensuring an air flow gap of 8 inches up and down, and 2 inches around. It should be fixed by drilling holes according to the template. For the IP54 model, the front cover and rubber plug need to be removed first.

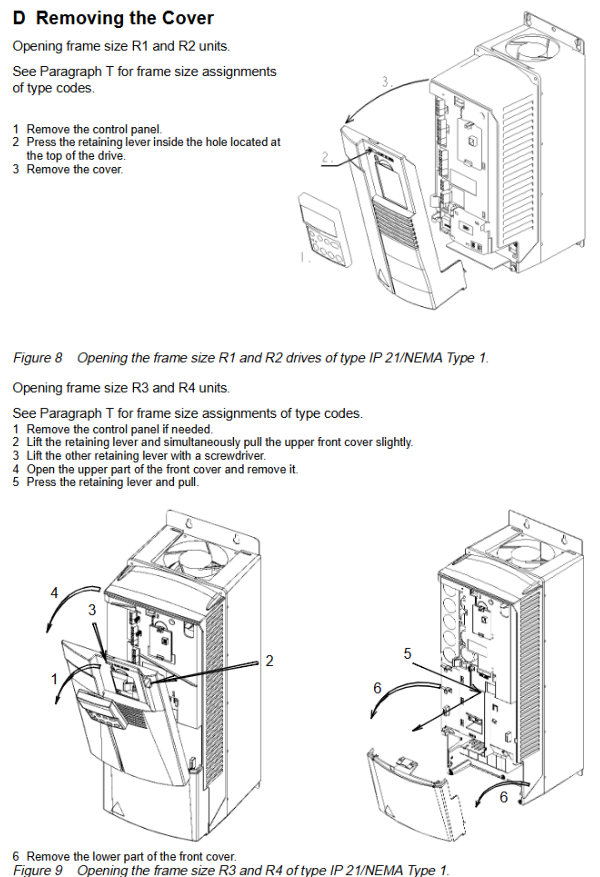

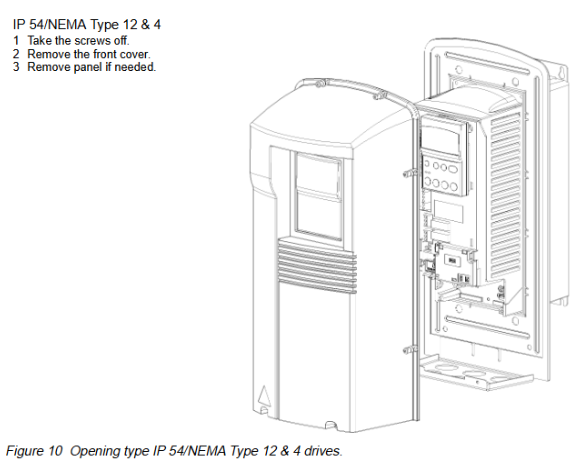

Dismantling and installation of cover plate: The steps for disassembling and installing cover plate are different for drivers with different frame sizes and protection levels. The IP21 and IP54 models of R1, R2, R3, and R4 have their own operating points.

Terminal interface and warning stickers: Terminal interfaces include power, control, communication, and jumper terminals, and warning stickers need to be pasted at designated locations.

Cable connection: Clearly define the connection requirements for each terminal (power input, motor output, DC bus, control wiring, etc.), follow local cable specifications and standards, separate different types of wiring, use shielded cables for control wiring, specific temperature levels for power cables, and mention relevant content on motor protection.

Technical parameters and protection functions

Technical parameters: The rated motor power (square torque and constant torque), input-output current, maximum output current, switching frequency, protection limits (overcurrent, overvoltage, etc.), maximum terminal diameter and screw torque, line fuse and other parameters for different frame sizes are listed in detail, with inputs of 208-240V and 380-480V.

Protection function: It has multiple protection functions such as overcurrent, overvoltage, undervoltage, overheating, output grounding fault, output short circuit, input phase loss, I/O terminal short circuit protection, motor overload protection, output overload protection, locked rotor protection, underload, etc. The LED indicator light will display the corresponding alarm and fault status.

Programming and Operations

Control Panel (ACS-PAN-B): It is an alphanumeric panel with backlit LCD, which can be connected and removed, supports parameter copying, has manual, automatic, stop and other control modes, displays output frequency and other information, and can adjust display contrast.

Menu structure and parameter settings: Contains multiple parameter groups, with basic parameters initially visible, and the full parameter set can be selected through the menu function. Setting parameter values requires entering the setting mode, where default values can be viewed.

Application macros: preset parameter sets, including HVAC Hand Auto, HVAC Floating Point, HVAC PID Control, HVAC PFC Control, etc. After selection, all parameters except for specific parameters will be set as default values. Different macros have different input and output signals and parameter values.

Diagnosis and fault handling

Alarm and fault codes: List the codes, messages, and descriptions of various alarms (such as operation failure, startup activation, etc.) and faults (such as overcurrent, DC overvoltage, etc.). Faults can be reset through the control panel, and some require power-off reset.

Diagnostic counters: Diagnostic counters related to Modbus communication, such as error messages, good messages, etc., can be used to debug fieldbus systems and can be reset through control panel or serial communication.

Communication function

Standard Serial Communication: Supports Modbus protocol and can be connected to external control systems. There are two serial communication channels, Channel 1 is a Modbus fieldbus connection and requires activation of relevant parameters.

Communication settings: including station number, communication speed, parity check, etc., which need to be consistent with the main device settings. Control position, output signal source, etc. can also be configured.

Modbus protocol: introduces the protocol related register mapping, exception codes, function codes, control words, status words, actual values, and other related content.

Appendix

Local and Remote Control: Explain the differences and settings between local control (via control panel) and remote control (via digital/analog input, serial communication).

PFC Macro: Introduction to pump and fan control macros, including control principles, PID controllers, relay outputs, I/O extensions, etc.

Dimensional drawing: Provide detailed dimensional drawings of ACH 400 drives with different protection levels and frame sizes.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923