K-WANG

ABB AO2040-CU Ex Central Unit

ABB AO2040-CU Ex Central Unit

The specialized operating guide for ABB AO2040-CU Ex central unit (2G class) serves as a supplement to the main operating manual for the AO2000 series continuous gas analyzer (publication number 42/24-10 EN), containing key information for safe installation, start-up, and operation of the equipment. The "Analyzer Data Sheet" accompanying each device should be used in conjunction with this manual. The symbols "1, 2, 3,..." in the manual indicate safety operation points, and the symbol "●" indicates specific instructions for equipment operation.

Technical Parameter

Compliant with standards: Compliant with DMT 08 ATEX 2018 U 605 standard, explosion-proof mark Ex de IIC T4 Gb, equipment category 2G, suitable for use in Zone 1 and Zone 2 explosion hazardous areas.

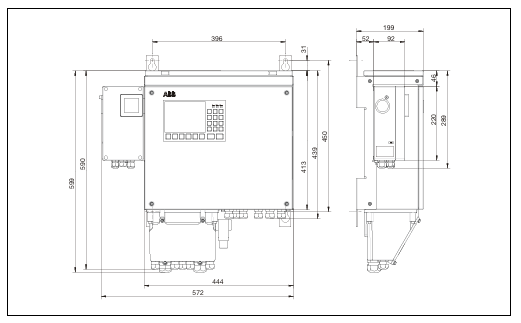

Size and weight: The equipment size is not explicitly mentioned, with a weight of approximately 28kg.

Suppress gas related parameters

Gas type: Use air that meets ISO 8573-1 standard level 3 as the suppression gas.

Gas quality requirements: maximum particle size of 40 μ m, maximum oil content of 1mg/m ³, maximum pressure dew point+3 ° C.

Working pressure range: Suppress gas working pressure to 250-500kPa (2.5-5bar).

Power supply parameters

Voltage setting: Before connecting to the power supply, it is necessary to confirm that the equipment voltage setting matches the line voltage. The specific voltage setting value is not explicitly mentioned.

Power protection device: Install suitable protection devices and easy to operate circuit breakers, specific specifications are not explicitly mentioned.

Pressure parameters

Positive pressure inside the system casing: Maintain a positive pressure of approximately 2hPa inside the system casing during operation.

Positive pressure alarm and protection threshold: When the positive pressure is below 0.8hPa or above 15hPa, disconnect the power supply and isolation relay connection circuit inside the system enclosure; When the internal pressure is below 1.2hPa, a status signal is output through passive relay contacts.

Electrical connection parameters

Potential compensation connection: External potential compensation connection or protective wire with a minimum cross-sectional area of 4mm ².

Intrinsic safety signal circuit: The total length of the intrinsic safety signal circuit for the condensate water monitor shall not exceed 75 meters, and a 100k Ω resistor shall be installed next to the sensor.

Cable connector specification: M20 threaded connector is suitable for cable outer diameters of 6-12mm.

Safety operation information

General safety requirements: The equipment must be properly handled, stored, installed, set up, operated, and maintained; Only personnel who are familiar with similar equipment and have relevant qualifications can operate it; It is necessary to comply with the content of this manual, equipment safety information, safety precautions for electrical equipment and gas operation, as well as explosion-proof regulations and standards.

Special safety instructions: Follow all explosion-proof safety measures before operation; Do not operate current carrying components in explosive risk environments except for intrinsically safe circuits; Connect the local potential compensation point first; Ensure that the equipment voltage setting matches the line voltage; Before opening the casing, disconnect all power sources and wait for 10 minutes for the power capacitor to discharge; If the equipment is damaged, unable to operate, or has poor storage and transportation conditions, it should be stopped from use.

Installation guide

Unpacking and installation: The equipment weighs approximately 28kg and requires two people to operate. The installation position should be stable; Can be installed in Zone 1 and Zone 2 explosion hazardous areas, and cannot be installed outdoors.

Suppression gas pipeline connection: Use air that complies with ISO 8573-1 Level 3 as the suppression gas; Install the accompanying compressed air conditioning filter to prevent valve damage caused by gas pipeline contamination.

Electrical connection safety precautions: Do not change the internal wiring of the factory, only modify the wiring between the isolation relay and the system controller and I/O board connectors; First, connect the external potential compensation connection or protective wire, with a minimum conductor cross-sectional area of 4mm ²; Electrical circuits need to be firmly fixed, and shielded wires need to pass through metal connectors; The intrinsic safety signal line is only connected to the blue cable connector, with a minimum distance of 8mm from other lines; the communication interface line needs to be connected through factory pre wired isolation relays; Connect the power line to the pressurized enclosure system control unit, do not directly connect it to the system enclosure port.

Electrical connection details: Clarify the application of different types of connectors (light blue M20, black M20, metal M20); The M20 threaded connector is suitable for cable outer diameters of 6-12mm. Unused connectors need to be sealed with original plugs and tightened.

Electrical equipment composition: including isolation relays, terminal blocks, line filters, pressurized enclosure system control units, isolation amplifiers, etc.

Each device has its specific functions and connection requirements.

Analysis module connection: The system bus and 24VDC cable are components of the pressurized enclosure system, with a length of not less than 1 meter; Connect the system bus cable and 24VDC cable to the central unit according to the steps.

Non intrinsic safety signal line connection: connected to the right side of the isolation relay; The intrinsic safety signal circuit of the condensate monitor is connected through a bright blue cable, with a total length not exceeding 75 meters, and a 100k Ω resistor is installed next to the sensor.

Status signal, potential compensation and power connection: The minimum cross-sectional area of the conductor for potential compensation connection is 4mm ²; Connect the status signal to control unit terminals 21 and 22; Before connecting the power supply, confirm that the voltage settings match, install appropriate protective devices and easy to operate circuit breakers, and connect control unit terminals 15, 17 and PE terminals.

Operation and maintenance

Pre start inspection: Confirm that the installation site conditions, equipment installation firmness, suppression of gas flow, shell integrity, electrical circuit connections, etc. meet the requirements.

Startup steps: Connect the power supply and suppress the gas supply. After the initial purge is completed, switch the solenoid valve to "leakage compensation" and activate the power supply of the equipment inside the system casing; After startup, the "Power", "Maintenance", and "Error" LEDs light up, and the screen displays the startup phase and software version, then switches to measurement mode.

Maintenance bypass operation: When there is no explosive environment, the bypass of the pressurized shell system control unit can be activated, which requires approval from the operations manager; Activate and deactivate the bypass according to the steps, and the bypass must be deactivated during normal operation.

Regular inspection: Conduct routine checks according to the pre startup checklist.

Appendix: Application and Design

Application and Design Overview: Used in conjunction with the AO2060 series analysis module to control and monitor the measurement and control process; The system casing is wall mounted and designed to comply with EN 60079-2 "pressurized casing with leakage compensation"; Can access intrinsic safety and non intrinsic safety signal circuits, and the system controller has no battery backup.

Pressure shell system: using air that complies with ISO 8573-1 Level 3 as the suppression gas, with a particle trap at the outlet; Perform preliminary blowdown set by the factory during startup, and maintain a positive pressure of approximately 2hPa inside the system casing during operation; When the positive pressure is lower than 0.8hPa or higher than 15hPa, disconnect the power supply and isolation relay connection circuit of the equipment inside the system casing, and after the pressure is restored, blow and activate again; When the internal pressure is below 1.2hPa, a status signal is output through passive relay contacts.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive