+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

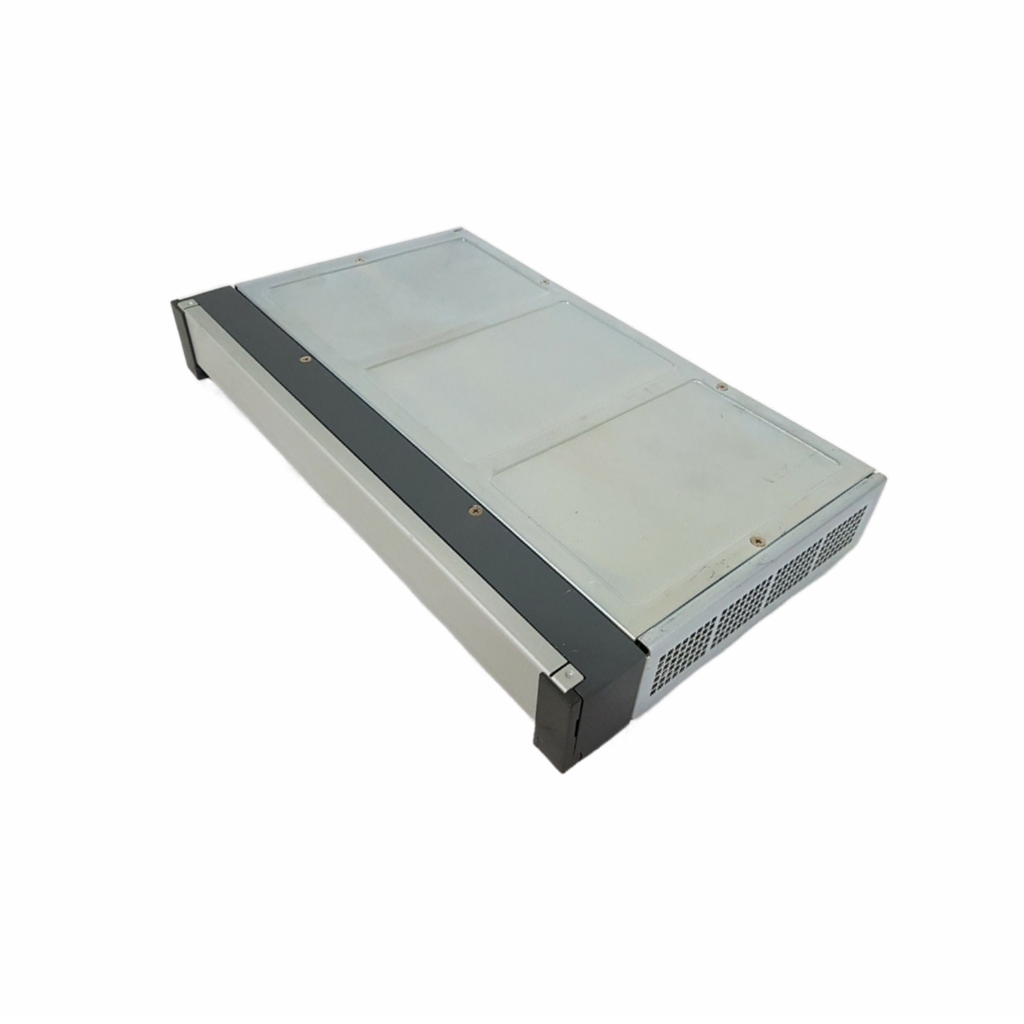

ABB CB801 3BSE042245R1 PROFIBUS DP panel communication unit

ABB CB801 3BSE042245R1 PROFIBUS DP panel communication unit

ABB CB801 3BSE042245R1 PROFIBUS DP panel communication unit

Bay unit (500BU03)

The bay unit (see Fig. 4) is the interface

between the protection and the primary sys tem process comprising the main CTs, isola tors and circuit-breaker and performs the

associated data acquisition, pre-processing,

control functions and bay level protection

functions. It also provides the electrical insula tion between the primary system and the

internal electronics of the protection.

The input transformer module contains four

input CTs for measuring phase and neutral

currents with terminals for 1 A and 5 A. Addi tional interposing CTs are not required,

because any differences between the CT

ratios are compensated by appropriately con figuring the software of the respective bay units.

Optional input transformer module also con tains five input voltage transformers for the

measurement of the three-phase voltages and

two busbar voltages and recording of voltage

disturbances or 6 current transformers for

transformer differential protection. (see Fig. 12).

In the analog input and processing module,

the analog current and voltage signals are

converted to numerical signals at a sampling

rate of 48 samples per period and then

numerically preprocessed and filtered accord ingly. Zero-sequence voltage and zero-current

signals are also calculated internally. The Pro cess data are transferred at regular intervals

from the bay units to the central processing

unit via the process bus.

Every bay unit has 20 binary inputs and 16

relay outputs. The binary I/O module detects

and processes the positions of isolators and

couplers, blocking signals, starting signals,

external resetting signals, etc. The binary

input channels operate according to a pat ented pulse modulation principle in a nominal

range of 48 to 250 V DC. The PC-based HMI

program provides settings for the threshold

voltage of the binary inputs. All the binary out put channels are equipped with fast operating

relays and can be used for either signaling or

tripping purposes (see contact data in Table 8).

A software logic enables the input and output

channels to be assigned to the various func tions. A time stamp is attached to all the data

such as currents, voltages, binary inputs,

events and diagnostic information acquired by

a bay unit.

Where more binary and analog inputs are

needed, several bay units can be combined to

form a feeder/bus coupler bay (e.g. a bus cou pler bay with CTs on both sides of the bus-tie

breaker requires two bay units).

The bay unit is provided with local intelligence

and performs local protection (e.g. breaker

failure, end fault, breaker pole discrepancy),

bay protection (Main 2 or back-up bay protec tions) as well as the event and disturbance

recording.

In the event that the central unit is out of operation or the optical fiber communication is disrupted an alarm is generated, the bay unit will

continue to operate, and all local and bay protection as well as the recorders (event and

disturbance) will remain fully functional

(stand-alone operation).

The hardware structure is based on a closed,

monolithic casing and presented in two

mounting solutions:

• Without local HMI: ideal solution if convenient access to all information via the central unit or by an existing substation

automation system is sufficient.

• With local HMI and 20 programmable LEDs

(Fig. 5): ideal solution for distributed and

kiosk mounting (AIS), since all information

is available in the bay.

For the latter option it is possible to have the

HMI either built in or connected via a flexible

cable to a fixed mounting position (see

Fig. 28).

In the event of a failure, a bay unit can be easily replaced. The replacement of a bay unit

can be handled in a simple way. During system start-up the new bay unit requests its

address, this can be entered directly via its

local HMI. The necessary setting values and

configuration data are then downloaded automatically.

Additional plug-and-play functionality

Bay units can be added to an existing

REB500 system in a simple way.

Fig. 5 Bay unit

Central unit (500CU03)

The hardware structure is based on standard

racks and only a few different module types

for the central unit (see Fig. 4).

The modules actually installed in a particular

protection scheme depend on the size, complexity and functionality of the busbar system.

A parallel bus on a front-plate motherboard

establishes the interconnections between the

modules in a rack. The modules are inserted

from the rear.

The central unit is the system manager, i.e. it

configures the system, contains the busbar

replica, assigns bays within the system, manages the sets of operating parameters, acts as

process bus controller, assures synchronization of the system and controls communication with the station control system.

The variables for the busbar protection function are derived dynamically from the process

data provided by the bay units.

The process data are transferred to the central processor via a star coupler module. Up to

10 bay units can be connected to the first central processor and 10 to the others. Central

processors and star coupler modules are

added for protection systems that include

more than 10 bay units. In the case of more

than 30 bay units, additional casings are

required for accommodating the additional

central processors and star coupler modules

required.

All modules of the central unit have a plugand-play functionality in order to minimize

module configuration.

One or two binary I/O modules can be connected to a central processing unit.

The central unit comprises a local HMI with 20

programmable LEDs (Fig. 6), a TCP/IP port

for very fast HMI500 connection within the

local area network.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

51

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923