K-WANG

Rockwell Automation ControlLogix 5570 and 5560 controllers

Features ControlLogix 5570 ControlLogix 5560

Power Supply and Memory Backup Energy Storage Module (ESM) Lithium Battery (1756-BA1/BA2/BATM)

Built in communication port USB 2.0 (temporary programming only, cable length ≤ 3m, no hub) RS-232 serial port

The maximum number of connections is 500 and 250

Non volatile storage SD card (standard 1784-SD1 1GB) CompactFlash card (available separately)

Status display: 4-line scrolling text screen+4 indicator lights, 6 indicator lights (no text screen)

Representative models 1756-L71/L72/L73/L74/L75 1756-L61/L62/L63/L64/L65

Rockwell Automation ControlLogix 5570 and 5560 controllers

Product Overview and Classification

1. Controller types and core differences

The ControlLogix series controllers are divided into two major series, 5570 and 5560, as well as extreme environment type (- XT suffix) and Armor protection type (- EROM suffix). The core differences are as follows:

Features ControlLogix 5570 ControlLogix 5560

Power Supply and Memory Backup Energy Storage Module (ESM) Lithium Battery (1756-BA1/BA2/BATM)

Built in communication port USB 2.0 (temporary programming only, cable length ≤ 3m, no hub) RS-232 serial port

The maximum number of connections is 500 and 250

Non volatile storage SD card (standard 1784-SD1 1GB) CompactFlash card (available separately)

Status display: 4-line scrolling text screen+4 indicator lights, 6 indicator lights (no text screen)

Representative models 1756-L71/L72/L73/L74/L75 1756-L61/L62/L63/L64/L65

2. Special Model Description

Extreme environment type (- XT): such as 1756-L73XT/L63XT, supports working temperatures of -25~+70 ° C, and other functions are consistent with the corresponding basic model.

Armor protective type (- ROM): such as 1756-L72EROM/L73EROM, integrated with 1756-L7x controller and 2 EtherNet/IP DLR communication modules, IP67 protection level, suitable for machine installation, ESM non removable.

Installation and hardware configuration

1. Installation environment requirements

Environmental conditions: Pollution level 2 industrial environment, overvoltage category II, altitude ≤ 2000m, no derating requirements; Storage temperature -40~+80 ° C, working temperature for conventional type 0~+60 ° C, extreme type -25~+70 ° C.

Shell requirements: It needs to be installed in a shell that complies with NEMA 250 or IEC 60529 standards, with a flame retardant rating of 5VA (non-metallic shells need to be certified), and can only be opened with tools inside. The explosion-proof environment needs to additionally comply with ATEX/IECEx requirements (such as Zone 2 environment requiring an IP54 or above shell).

2. Core hardware installation steps

(1) Key installation of ControlLogix 5570

**Chassis and power supply pre installation * *: Chassis and power supply need to be installed according to the manuals "1756-IN621 (Chassis)" and "1756-IN619 (Power Supply)" first.

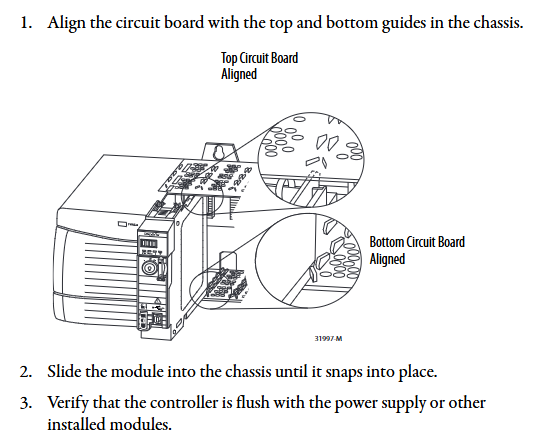

Controller insertion: Align the upper and lower rails of the chassis, slide in to the buckle lock, and ensure that it is flush with adjacent modules; Attention should be paid to the risk of electric arc in explosion-proof environment during live plugging and unplugging. It is recommended to perform power-off operation.

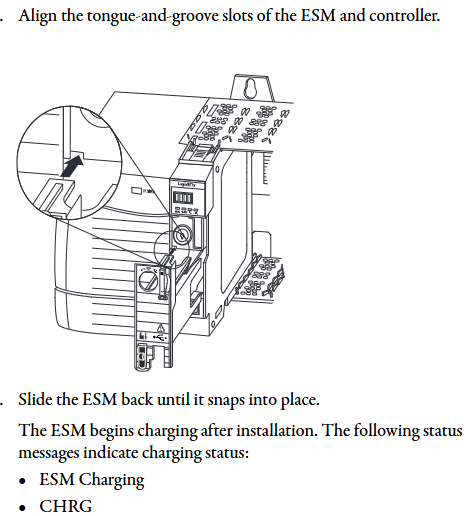

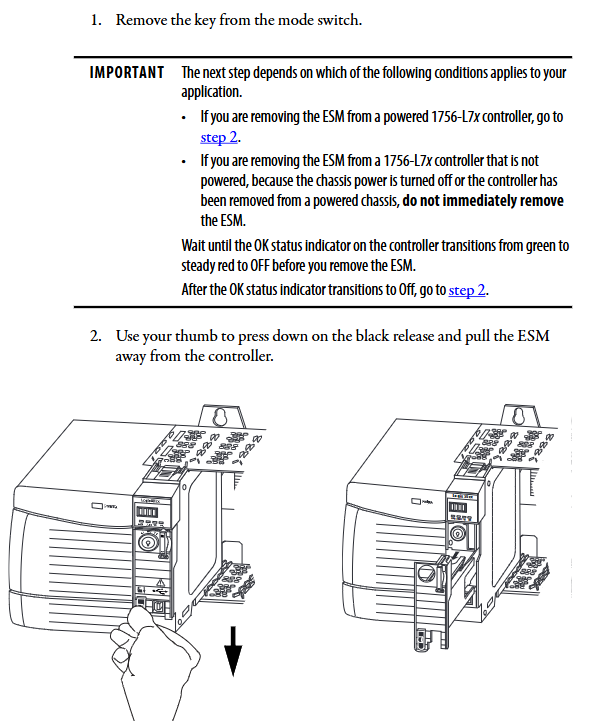

ESM installation: Align with the tongue and grain slot and push it into the buckle for fixation. After installation, start charging (up to 2 minutes, the status screen displays "CHRG"). Do not turn off the power before charging is complete, otherwise the program may be lost.

SD card operation: Open the SD card card, insert the 1784-SD1/SD2 card (recommended original card to avoid data damage), and press it until the card buckle locks; Before removal, it is necessary to confirm that the SD indicator light is off and that the explosion-proof environment requires power-off operation.

(2) Key installation of ControlLogix 5560

Battery installation: Series A uses 1756-BA1/BATM, Series B uses 1756-BA2, connect the positive and negative poles (red+black -), write the replacement date and paste it on the inside of the cabinet door.

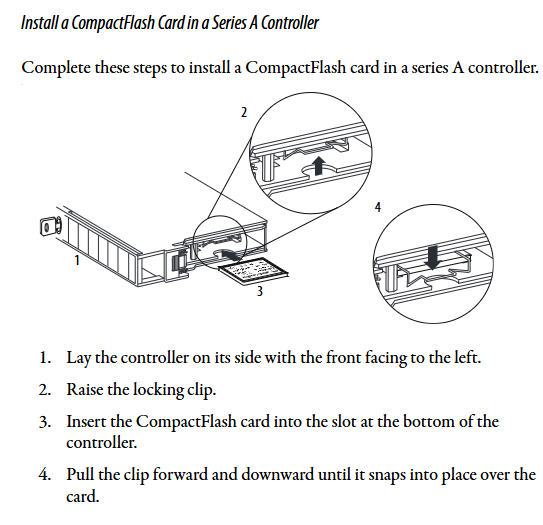

CompactFlash card operation: Series A needs to lift the locking clip to insert, Series B needs to push open the buckle and insert, and before removing, confirm that the OK indicator light is green.

3. Hardware security specifications

Static protection: Before operation, touch grounded objects to discharge electricity, wear a grounding wristband, avoid touching connector pins and internal circuits, and use anti-static workstation storage devices.

Explosion proof requirements: In Class I Zone 2 (Groups A-D) environments, equipment/components can only be plugged in and out after power failure or confirmation of non hazardous areas; It is prohibited to replace non certified components, and batteries must be replaced in non hazardous areas.

Software configuration and firmware upgrade

1. Essential software and version requirements

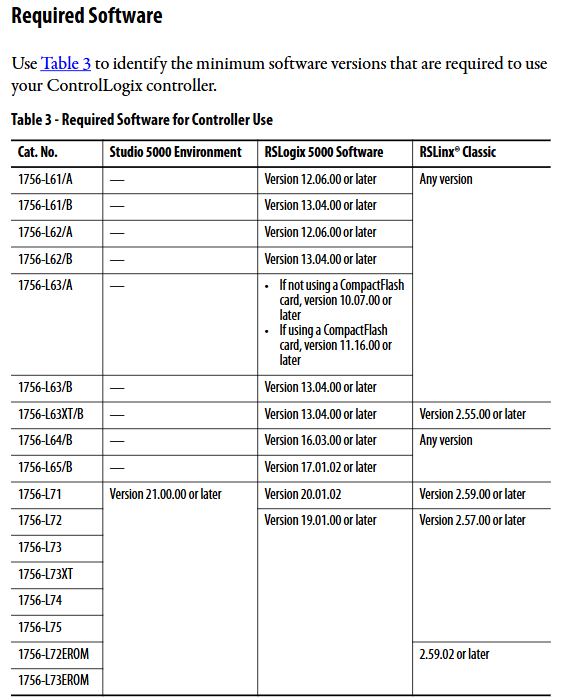

Different controller models need to be matched with specific software versions, and the core requirements are as follows:

Controller model Studio 5000 environment minimum version RSLogix 5000 minimum version RSLinx Classic minimum version

1756-L71/L72/L73 and other V21.00.00 V20.01.02 V2.59.00

1756-L61/A - V12.06.00 any version

1756-L63XT/B - V13.04.00 V2.55.00

2. Firmware upgrade method

Supports two methods: ControlFLASH software and AutoFlash (built-in in Logix Designer). The steps are as follows:

(1) ControlFLASH upgrade

Connect the controller (USB/Ethernet), start ControlFLASH, select the controller model and network driver.

Select the target firmware version (download the matching version from the official website to avoid file corruption), click "Finish" to start the upgrade, and do not turn off the power during the process.

After the upgrade is completed, the controller automatically restarts and the confirmation status screen displays the new firmware version (such as "Rev 30.011").

(2) AutoFlash upgrade

Create a project in Logix Designer, click on "Who Active" to find the target controller, and select "Update Firmware".

Select the firmware file path and version, confirm that the controller is in "Remote Program" mode and there are no uncleared faults, and click "Update".

During the upgrade process, the progress is displayed (5570 points for "update count/block count", 5560 only displays "block count"), and the firmware version is verified after completion.

3. Memory and storage configuration

5570 series: SD cards are used to store project and fault logs, supporting three modes: "power on load", "load when memory is damaged", and "user triggered load". Locking the SD card can prevent firmware from being overwritten.

5560 series: The CompactFlash card needs to be configured with the "store/load" parameter in Logix Designer, supporting program backup and recovery. When replacing the battery, ensure that there is a backup in the card to prevent data loss.

Communication network configuration

1. Supported communication protocols and modules

The controller supports multiple types of industrial networks and requires corresponding communication modules. The core configuration is as follows:

Network type, communication module model, core function, maximum number of connections/bandwidth limit

EtherNet/IP 1756-ENBT/EN2TR/EN3TR supports production and consumption tags, I/O control, and HMI communication. 1756-EN3TR supports 256 movements in 128 axes (EN2T/EN2TR); 128 (ENBT)

ControlNet 1756-CNB/CN2/CN2R/CN2RXT deterministic real-time communication, supporting 64 redundant media (CN2R/CN2RXT) (CNB/CNBR); 128 (CN2/CN2R)

DeviceNet 1756-DNB connects distributed I/O and drivers, supports scanning list configuration with 124 DINT input/123 DINT output

Data Highway Plus (DH+) 1756-DHRIO/DHRIOXT connects PLC-5/SLC controllers, supporting 32 sites at 57.6/115.2/230.4 kbps rates

HART 1756-IF8H/OF8H analog I/O+digital signal superposition, supports direct connection to HART transmitter for device diagnosis

2. Key steps for communication configuration

(1) EtherNet/IP configuration

Add modules such as 1756-EN2T in the "I/O Configuration" of Logix Designer and set the IP address (supporting BOOTP/DHCP allocation).

Configure "Production/Consumption Tags": Production tags need to specify the number of consumers, while consumption tags need to match the production tag data type and RPI (Request Packet Interval).

Remote I/O configuration: Reduce the number of connections through "rack optimization connections", and a single connection can cover the entire remote rack I/O.

(2) Serial Communication (5560 Series)

Connect the 1756-CP3 serial port cable, configure the "RS-232 DF1 device driver" in RSLinx, and select the "Logix 5550/CompactLogix" device type.

Supporting protocols: DF1 master-slave/point-to-point/wireless modem, DH-485, ASCII, Modbus (requiring MSG instruction programming), ASCII protocol requires configuring buffer size (1-4096 bytes) and termination characters.

Programming and Application Development

1. Control program structure

The Logix 5000 control program consists of a three-level structure of "task program routine", with the following core rules:

Tasks (up to 32):

Continuous task (1): lowest priority, utilizing idle CPU time for cyclic execution.

Periodic task: Execute at set intervals (0.1~2000000ms), priority 1~15 (highest 1).

Event task: triggered by triggering conditions (such as I/O status changes, consumption tag triggers) for execution.

Program (up to 1000 per task, V24+): Contains local tags, parameters, main routines, fault routines, supports "scheduled execution" (executed in sequence) and "unplanned execution" (only verified and not running).

Routine: executable code written in a single programming language, supporting ladder diagrams (LD), function block diagrams (FBD), structured text (ST), and sequential function diagrams (SFC).

2. Core programming functions

(1) Production/Consumption Tags (Interlock Data)

Production label: One controller releases data, and multiple controllers (up to 32) consume it simultaneously. It must be on the same network (not bridged across networks), and the data type and array dimension must be consistent.

Connection calculation: The production label occupies "number of consumers+1" controller connection, the consumption label occupies 1 connection, and the communication module occupies an additional 1 connection.

(2) MSG instruction (message communication)

Supports types such as "CIP Data Table Read/Write", "PLC-5/SLC Communication", "General CIP", etc. It can cache connections (optimize speed during repeated execution, up to 32 cache connections) or non cache connections (release connections after execution).

Block Transfer requires the configuration of a "request/response" data area, which is suitable for high-speed counters, frequency converters, and other devices.

(3) Motion control

Supports EtherNet/IP integrated motion (Kinetix 350/5500/6500 drivers), Sercos interface (1756-M03SE/M08SE module), and analog interface (1756-HYD02 module).

Core instructions: MSO (servo enable), MAH (axis return to zero), MAJ (axis jog), MAM (axis positioning), need to create "axis labels" and configure parameters such as speed and acceleration.

3. PhaseManager tool (device phase control)

Function: Divide device operation stages (such as Resetting/Running/Holding) according to the S88/Pack ML state model, simplify process programming, support "action state" (executing operations) and "waiting state" (waiting when conditions are met).

Core instructions: PSC (Stage Completion Signal), PCMD (Stage State Switching), PFL (Stage Fault Signal), which need to be enabled in Logix Designer V21+and support multitasking scheduling.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923