K-WANG

ABB Digitic 500 Industrial Controller

ABB Digitic 500 Industrial Controller

Product overview

The Digitic 500 is a compact industrial controller suitable for single control loop instrumentation to small and medium-sized process automation, capable of completing simple to complex control tasks. Its documentation system includes installation manuals, debugging manuals, operation manuals, etc., and interface instructions (such as MODBUS) can also be provided upon request.

Basic configuration and functions

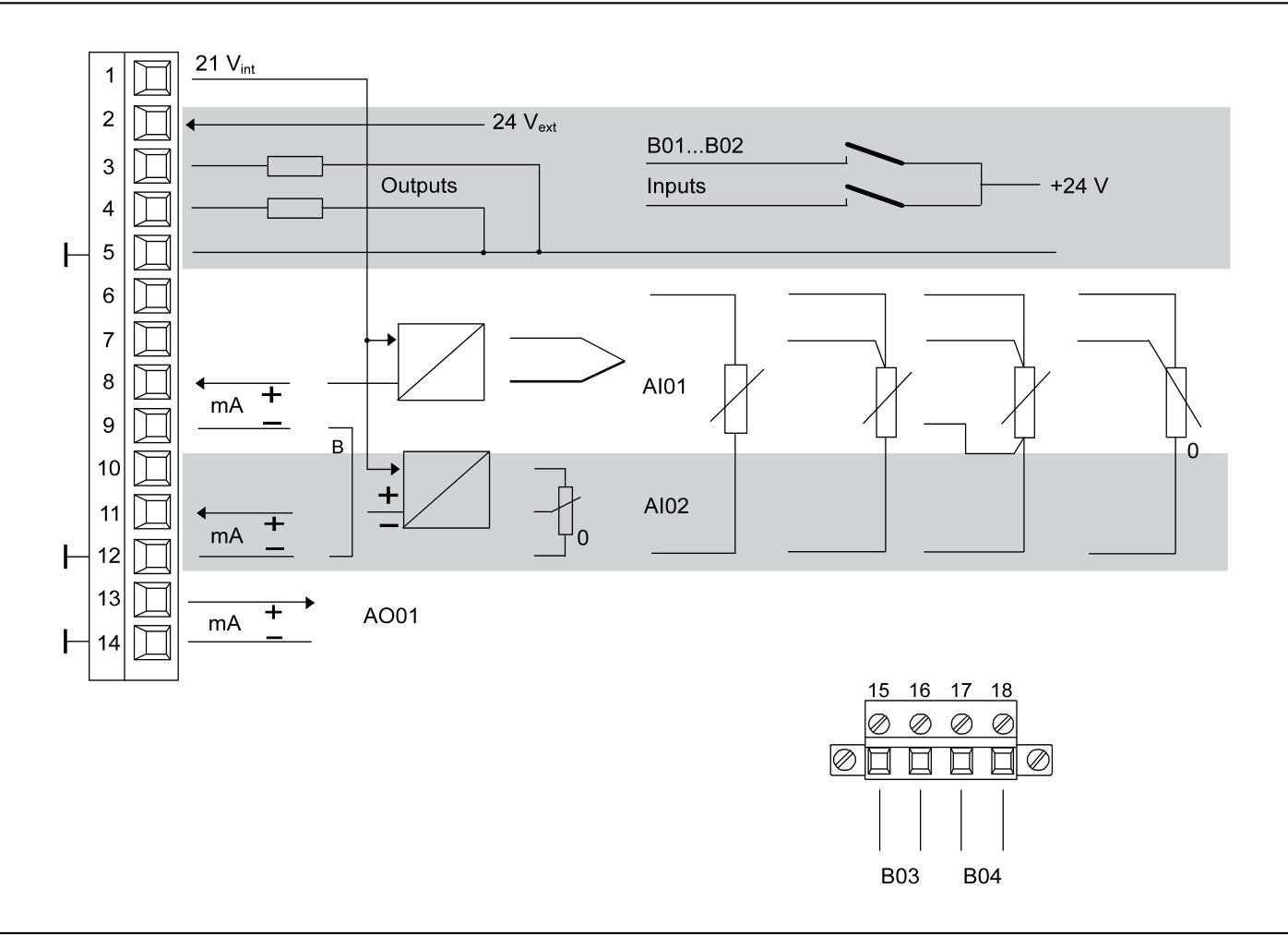

Basic version: Includes 1 universal input (supporting signals such as thermocouples, Pt100, transmitters, etc., with built-in standard sensor linearization table), 1 mA input (can be used as feedforward or setpoint input, and position feedback in stepper controllers), 1 mA output (for positioning signals, etc.), 2 configurable binary inputs/outputs, 2 relays (for executing signals, alarm outputs, etc.), and 4 module slots for expanding functions.

Programmer: Each controller includes a configurable programmer that can preset time related settings, store up to 10 programs, and each program contains 15 segments.

Controller output types: including two-point PID control, hot off cold control, step control, continuous control (optional split range output), etc.

Parameters and Configuration: Parameter settings require entering the password protected parameter level through the menu key; The configuration methods include list configuration (selecting standard functions from the built-in list of the device, which can be operated through IBISRR computer program) and free configuration (allowing customers to specific configurations, which can be added with logic control through the function plan editor).

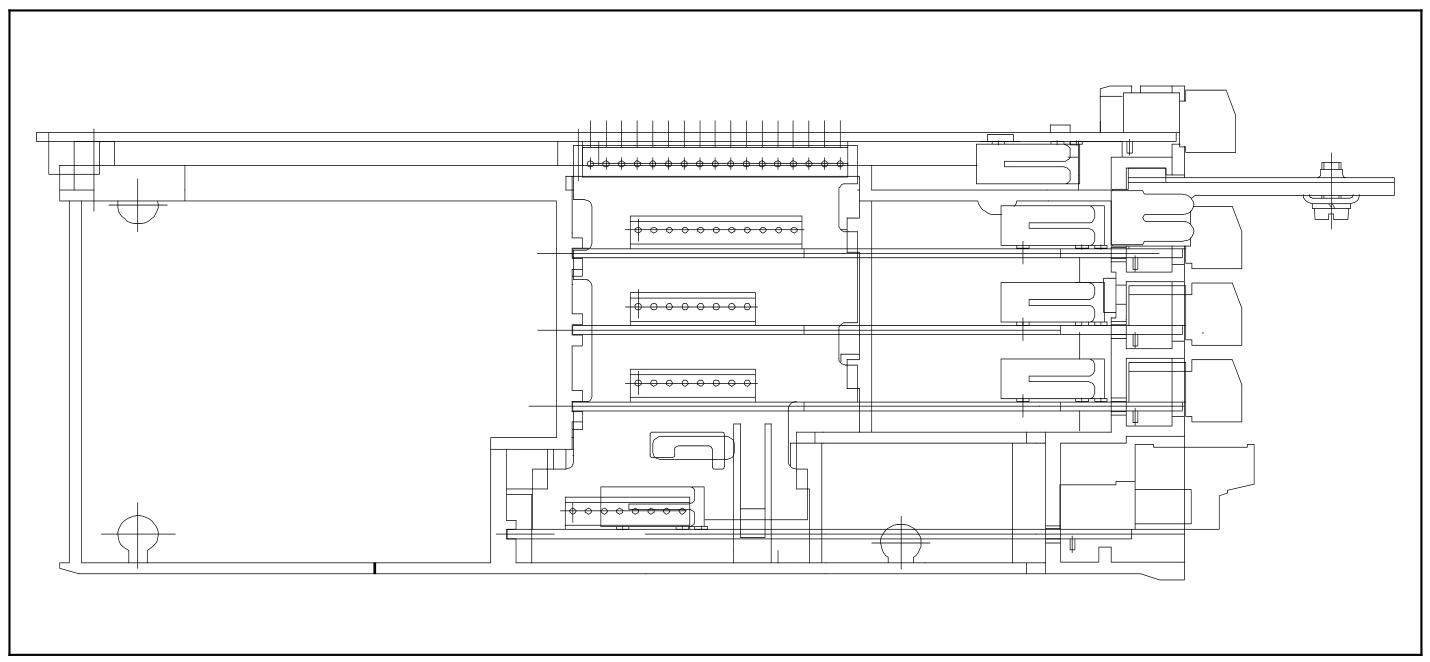

Installation process

Model identification: Identify the model through the side nameplate.

Installation location: Suitable for front installation in control rooms, control cabinets, and machines, ensuring that it does not exceed the climate and mechanical capacity limits specified in the "Technical Data".

Installation steps:

Panel opening: It must comply with DIN 43700 standard, with dimensions of 92+0.8mm × 92+0.8mm. When installed horizontally and tightly, the strip width should be at least 10mm, and at least 40mm ventilation space should be reserved above and below.

Fixed equipment: Remove the front panel dust cover, rotate the clamping claw screw counterclockwise until the clamping claw can be inserted into the panel, push the module into the panel opening, then rotate the screw clockwise to fix it, and finally reinstall the dust cover.

Connection instructions

Signal connection (basic model): using plug-in screw terminals, supporting solid or multi strand wires (maximum wire cross-section of 1.5mm ², maximum relay of 2.5mm ²), including interfaces for power connection, analog input/output, binary input/output, relay output, etc., with relay output up to 250V AC, 1A (cos φ=0.9).

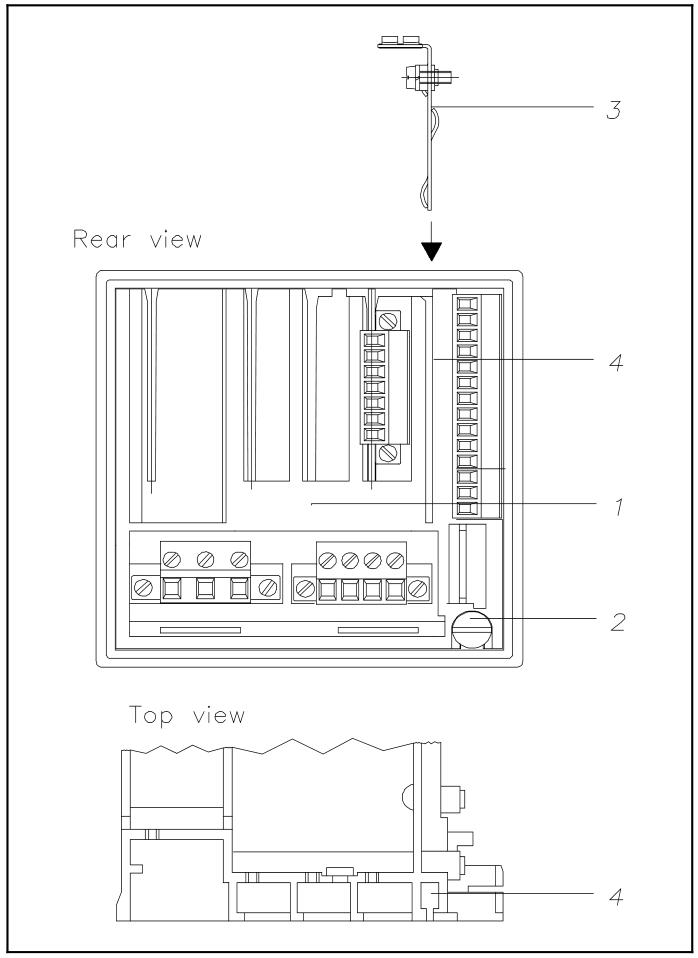

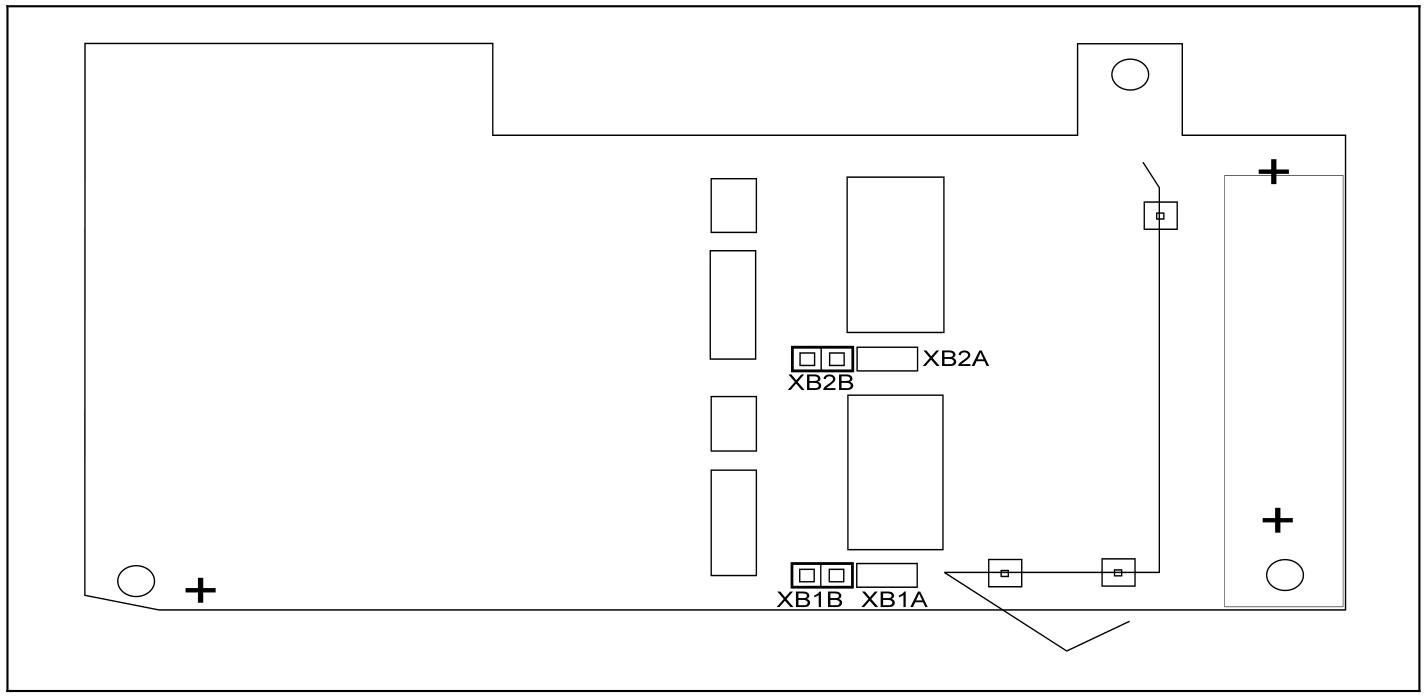

Module and computer connection: The backend includes shielded terminal boards, basic model signal connections, computer ports (configuration interfaces), relay outputs, power supply, and other interfaces.

Module type and configuration

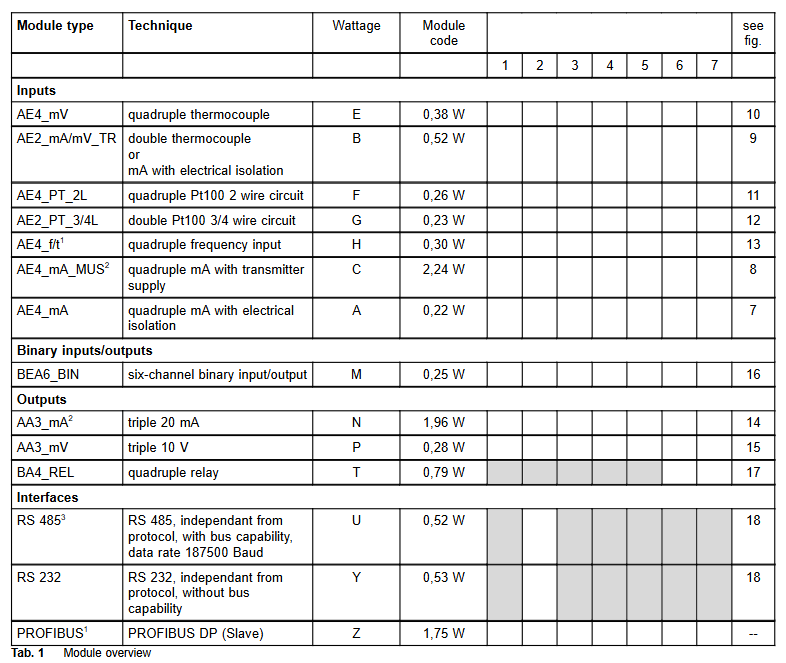

Available modules: including various analog input modules (such as 4 x mA, 2 x mA/thermocouple/mV, 4 x thermocouple, 4 x Pt100, etc.), binary input/output modules (6 channels), analog output modules (3 x mA, 3 x V), digital output modules (4 x relays), interface modules (RS-485, RS-232, PROFIBUS DP slave), etc., with a total of 4 module slots. There are no fixed slot restrictions for module allocation except for interfaces and relays.

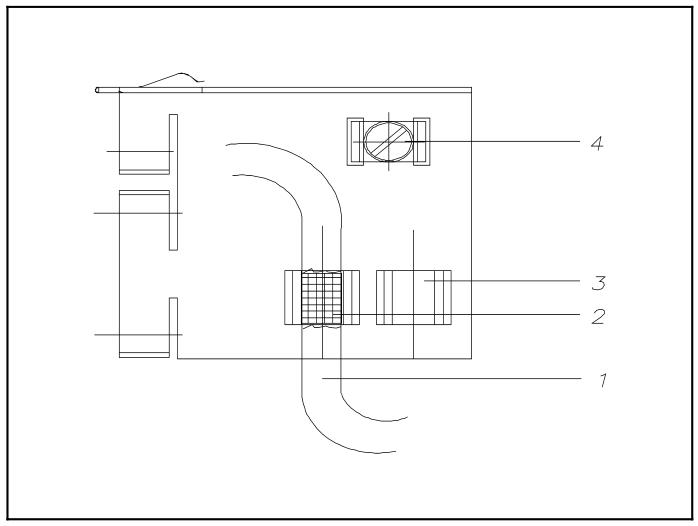

Module installation and replacement: Before installation, all hazardous voltages need to be disconnected. Remove the sub component by rotating the twisting screw of the sub component, insert the module into the guide slot from above and install it on the bus PCB, then push back the sub component and lock it; The installation and disassembly of the bus PCB require the use of a screwdriver to operate the snap fastener.

Power supply and grounding

Power connection: Supports 115/230V AC (90-260V, 47-63Hz) or 24V UC. Please follow the relevant power installation specifications and connect the protective grounding conductor before connection. The 24V power supply also needs to be connected to the grounding conductor.

Shielding treatment: A shielding terminal board needs to be installed to fix the shielding layer of the data cable on the contact surface. If there are auxiliary wires in the shielding layer, they can be connected to the terminal.

Technical Parameter

Input: Universal input resolution of 12 bits, measurement tolerance ≤ 0.2% (relative to nominal range), temperature impact ≤ 0.2%/10 ℃; Binary input/output is configurable, with a nominal input level of 24V DC and a maximum output of 100mA.

Output: Analog output 0/4... 20mA (maximum 750 Ω, short circuit and open circuit protection), resolution of 12 bits; The maximum output of the relay is 250V AC, 1A.

Environmental conditions: working temperature 0... 50 ℃, storage temperature -20... 70 ℃, relative humidity ≤ 75% (annual average), short-term up to 95% (slight condensation allowed); Meets EMC related standards and has strong anti-interference ability.

Mechanical parameters: front panel protection level IP65, shell IP30, terminal IP20; The panel size is 96mm × 96mm, the installation depth is 200mm, the weight is 1kg (without modules), each module weighs about 40g, and the relay module weighs about 80g.

Other information

Firmware upgrade and configuration: The firmware can be updated by replacing the IC. To enable free configuration, a specific IC is required. If the password is lost, it can be reset by adjusting the jumper.

Packaging and Accessories: Insulation and buffering should be done for transportation or return packaging. Accessories include various modules, bus PCBs, PC cables, adapters, etc. Please refer to the catalog number when ordering.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923