K-WANG

ABB E max series low-voltage molded case circuit breaker (Sace)

ABB E max series low-voltage molded case circuit breaker (Sace)

The ABB E max series low-voltage power circuit breaker (Sace) is an innovative product developed based on over half a century of circuit breaker technology. It has high reliability, easy installation, and flexible adaptability. It has passed UL certification and complies with ANSI low-voltage power circuit breaker standards, covering a rated continuous current range of 800A-5000A and a rated short-circuit current range of 42kA-125kA (480V). It is suitable for distribution systems, industrial equipment, and other scenarios, providing efficient power protection solutions for designers, switchgear manufacturers, installers, and users.

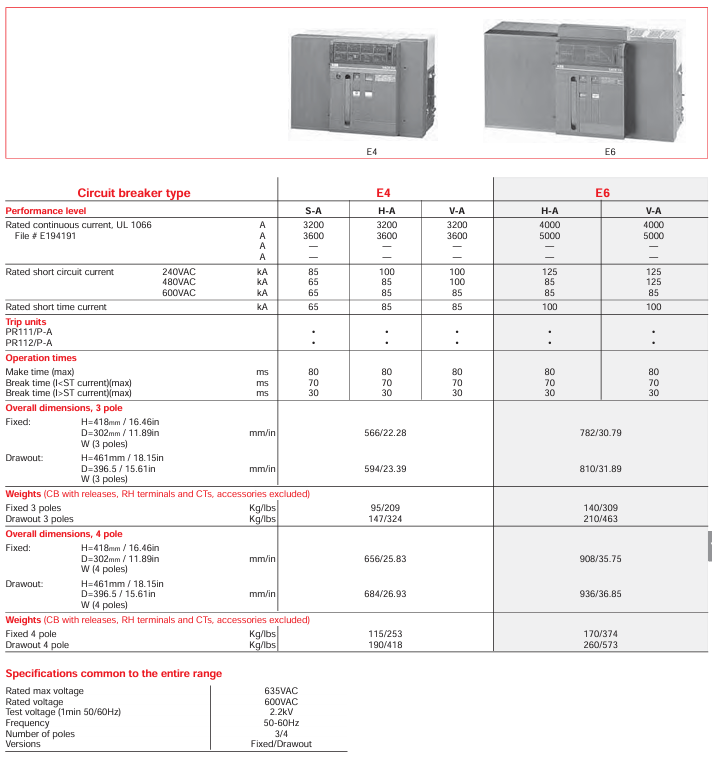

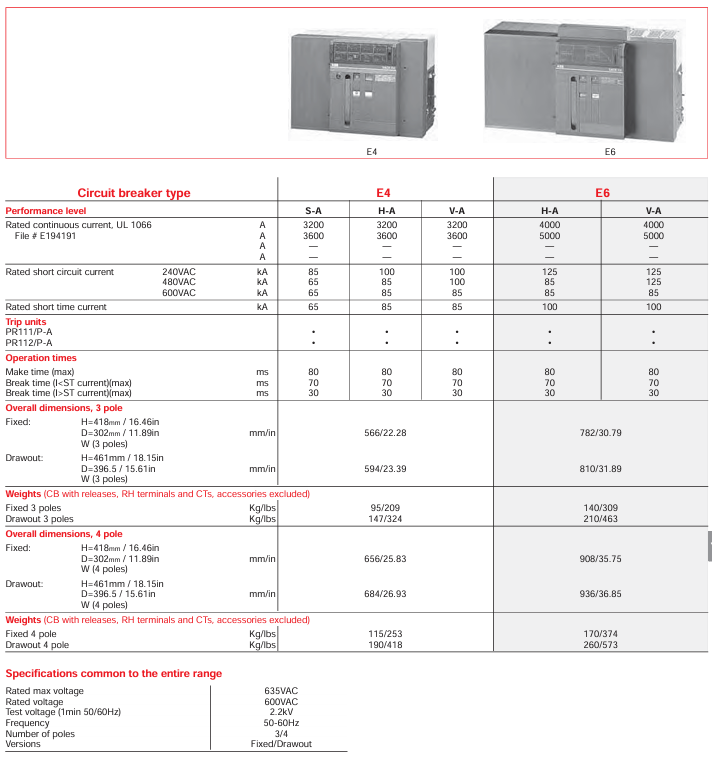

Core product classification and key parameters

1. Model and frame specifications

The series includes five models (four sizes): E1, E2, E3, E4, and E6. The differences in core electrical parameters are as follows (taking UL standards as an example):

Model Rated continuous current (A) 480V Rated short-circuit current (kA) Number of poles Installation method Typical weight (kg/lbs, 3 poles fixed)

E1 800-1200 42 3/4 fixed/pull-out 50/110

E2 1200-1600 50 3/4 fixed/extracted 55/121

E3 1200-2500 65-100 3/4 fixed/pull-out 80/176

E4 3200-3600 65-100 3/4 fixed/withdrawable 89/196

E6 4000-5000 85-125 3/4 fixed/withdrawable 125/275

2. General technical specifications (shared by UL and IEC)

Voltage and Frequency: Rated maximum voltage 635VAC, rated operating voltage 600VAC, test voltage (50/60Hz for 1 minute) 2.2kV, applicable frequency 50-60Hz.

Temperature range: Operating temperature -5~+70 ° C, storage temperature -40~+70 ° C, suitable for different temperature zones in industrial sites.

Neutral pole rating: The neutral pole rating for E1-E3 models is 100% of the rated current, and for E4-E6 models it is 50% (special requirements can be consulted with the manufacturer to customize the 100% rating).

Mechanical and electrical lifespan: Mechanical lifespan (under routine maintenance) 20000-25000 operations, electrical lifespan (440VAC) 10000-30000 operations, with a maximum operating frequency of 60 times per hour.

Core functions and structural characteristics

1. Protection and control capability

Release Unit: Standard PR111/P series release, supporting LI (Long Delay Instantaneous), LSI (Long Delay Short Delay Instantaneous), and LSIG (Long Delay Short Delay Instantaneous Ground Fault) protection functions; PR112/P and PR113/P series are optional, suitable for more complex scenarios (such as PR112/PD supporting communication functions).

Operation time: The maximum closing time is 80ms, the maximum opening time (I<short-circuit withstand current) is 70ms, and the maximum (I>short-circuit withstand current) is 30ms. It can quickly respond to faults and reduce equipment damage.

Auxiliary functions: Comes with 2NO+2NC auxiliary contacts (for indication of opening and closing status), spring energy storage/release mechanical indicators, and manual opening and closing buttons; The pull-out model is equipped with a rocking in device with a closed door, a rocking in position indicator, and an anti insertion lock to enhance operational safety.

2. Installation and structural design

Size and Installation: Fixed 3-pole model with a height of approximately 418mm (16.46 inches) and a depth of 302mm (11.89 inches); The pull-out depth has been increased to 396.5mm (15.61 inches), supporting DIN rail or 19 inch rack installation (requires installation kit).

Terminal and wiring: default rear horizontal terminal, optional rear vertical, front terminal and other types (such as "HH" representing rear horizontal and "HV" representing rear horizontal vertical in the model), suitable for different switchgear wiring requirements; The terminal box is integrated with the current transformer (CT) to simplify on-site wiring.

Redundancy and reliability: The pull-out model is designed with a "mobile part+fixed part" separation, supporting hot swappable replacement; Key components such as sliding contacts and trip units have anti vibration capabilities (7.35 m/S ², 5-500Hz) and comply with ISA S71.04 G3 harsh environment standards.

Product configuration and optional accessories

1. Basic configuration classification

According to the operation mode and function, there are mainly two types of products:

Automatic air circuit breaker: including trip unit and current transformer, supporting fault protection such as overcurrent and short circuit, divided into fixed and withdrawable types, suitable for distribution circuits that require automatic protection.

Non automatic air circuit breaker (switch): no trip unit and CT, only used as a manual or electric power switch, also available in fixed/withdrawable type, suitable for simple circuits that do not require complex protection.

2. Optional attachments (UL and IEC compatible)

Attachment category, specific function and model, example usage

Electrical accessories include shunt release coil (KE6S0, 24VDC), closing coil (KE6C6110-120VAC), and spring energy storage motor (KE6M5110-130VAC/VDC) for remote opening and closing and automatic spring energy storage

Mechanical accessory button protective cover (KE6PG), padlock device (KE6PD1), mechanical counter (KE6MC) to prevent misoperation, lock circuit breaker position, record operation times

Additional auxiliary contacts (KE6A15, 15 sets), position indicator contacts (KE6PS1, 5 sets), extended status monitoring signal, indication of withdrawable circuit breaker position

Interlocking and protective mechanical interlocking (KE6MLP, fixed circuit breaker base), transparent front cover (KE6DC, IP54 protection) achieve multi circuit breaker interlocking control and improve dust and water resistance

Test and Diagnostic Handheld Test Kit (K7TUT, suitable for PR111), Configuration Unit (PR010/T) for on-site testing of trip function and configuration of trip parameters

Model coding rules (taking UL as an example)

Taking "E1S16XXXXXXXXXX" as an example, the key codes have the following meanings to facilitate selection according to requirements:

Frame dimensions: 1=E1 (3 poles), 2=E2 (3 poles), 3=E3 (3 poles), 4=E4 (3 poles), 6=E6 (3 poles); A=E1 (4-pole), B=E2 (4-pole), etc.

Rated current: 08=800A, 12=1200A, 16=1600A, 20=2000A, 32=3200A, 50=5000A.

Breaking ability: B=basic, N=normal, S=standard, H=high, V=extremely high.

Release unit: A=PR111/P-LI, B=PR111/P-LSI, G=PR112/PD-LSI, etc.

Installation method: B=fixed type, D=pull-out type (excluding bracket).

Attachment code: X=no attachment, A=mechanical counter, B=mechanical trip indicator, F=A+B, etc., combined as needed.

Typical application scenarios

Power distribution: used for the main circuit of low-voltage distribution systems, protecting key equipment such as transformers and busbars, and adapting to E4-E6 high current models.

Industrial equipment: provides short-circuit and overload protection for industrial loads such as motors and frequency converters, and E1-E3 small-sized models are suitable for compact layout of switchgear.

Commercial buildings: As the main switch for power distribution, the pull-out design is convenient for later maintenance and replacement.

Compliance and Certification

Safety certification: UL/UL-C certification (applicable to Class I, Groups A-D, Division 2 explosion-proof areas), ATEX certification (Ex nA IIC T4, Zone 2 areas), IEC 60947-2 standard compliance.

Environmental requirements: Compliant with RoHS directive, halogen-free design, reduces harmful substance emissions, suitable for green industrial scenarios.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923