K-WANG

Beijer Mitsubishi Electric E1000 Series Operation Panel

The maximum ambient temperature for horizontal installation is 40 ° C, and for vertical installation it is 50 ° C.

There is an explosion risk warning, such as not disconnecting the equipment before power outage, component replacement may affect applicability, only UL and cUL certified expansion units are allowed to be connected (currently there are no relevant evaluated units), batteries need to be replaced in non hazardous areas, and AWG 28-12 cables need to be used to connect the power supply, with a minimum tightening torque of 0.5 Nm, and can only be used in 4X shell flat rooms.

Beijer Mitsubishi Electric E1000 Series Operation Panel

Safety precautions

UL and cUL installation requirements

The equipment is only suitable for Class I Zone 2 (Groups A, B, C, D) or non hazardous locations. The combination of equipment in the system must be inspected by the local competent department.

The maximum ambient temperature for horizontal installation is 40 ° C, and for vertical installation it is 50 ° C.

There is an explosion risk warning, such as not disconnecting the equipment before power outage, component replacement may affect applicability, only UL and cUL certified expansion units are allowed to be connected (currently there are no relevant evaluated units), batteries need to be replaced in non hazardous areas, and AWG 28-12 cables need to be used to connect the power supply, with a minimum tightening torque of 0.5 Nm, and can only be used in 4X shell flat rooms.

General Safety Rules

It is necessary to carefully read the safety precautions, inspect for transportation damage, and promptly notify the supplier. The use of equipment in high explosive risk environments is prohibited.

Suppliers are not responsible for modifying, altering, or reassembling equipment and may only use components and accessories that meet the supplier's specifications.

Before installation, use, or maintenance, it is necessary to read the relevant instructions to prevent liquids, metal debris, etc. from entering the equipment and causing fires or electric shocks, and only qualified personnel are allowed to operate.

The storage temperature of the device must meet the requirements, otherwise it may cause the LCD display liquid to solidify or denature. If the display liquid comes into contact with the skin or eyes, it should be handled in a specific way.

The illustrations in the manual are for illustration purposes only, and the supplier is not responsible for the actual use based on the illustrations, nor does they guarantee that the equipment is suitable for specific applications or assume responsibility for product design, installation, or operation.

Safety during installation

The operation panel should be fixedly installed on a flat surface without high explosion risk, strong magnetic field, direct sunlight, or drastic temperature changes, and installed and grounded according to the installation instructions, and only by qualified personnel.

High voltage cables, signal lines, and power lines need to be separated, and the voltage and polarity should be confirmed to be correct before connecting the power supply. Peripheral equipment should be adapted to the application scenario and location.

Safety during use

Keep the control panel clean. Emergency stop and other safety functions cannot be controlled by the control panel. Avoid using excessive force or sharp objects when operating buttons or touch screens.

Service and Maintenance of Security

Only qualified personnel are allowed to carry out repairs, following the agreed warranty terms. Before cleaning or maintenance, the power must be disconnected, and the display panel and front cover must be cleaned with a soft cloth and mild cleaning agent. The battery must be replaced according to the supplier's recommended model to avoid accidental replacement and explosion.

Disassembly and scrapping safety

The operation panel or its components need to be recycled according to local regulations. Components such as lithium batteries, electrolytic capacitors, and displays contain substances that may harm health and the environment.

Product Introduction

Product Model Classification and Parameters

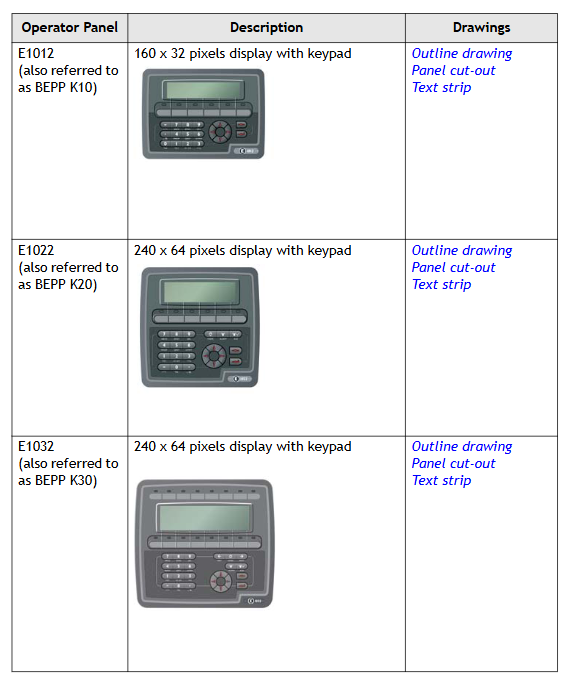

The E1000 series operation panel is divided into keyboard operation type and touch screen operation type. The specific models, descriptions, and corresponding drawings are as follows:

Type and Model Description Drawing

Keyboard operated E1012 (BEPP K10) 160 × 32 pixel display screen with keyboard outline, panel cutout, and text bar

E1022 (BEPP K20) 240 × 64 pixel display screen with keyboard outline, panel cutout, and text bar

E1032 (BEPP K30) 240 × 64 pixel display screen with keyboard outline, panel cutout, and text bar

E1060/E1062 (BEPP K60) 5.7-inch display screen with keyboard outline, panel cutout, and text bar

E1070 (BEPP 64K) 6.5-inch display screen with keyboard outline, panel cutout, and text bar

E1100 (BEPP 104K) 10.4-inch display screen with keyboard outline, panel cutout, and text bar

Touch screen operation type E1041/E1043 (BEPP T40) 3.5-inch touch screen display outline and panel cut diagram

E1061/E1063 (BEPP T60) 5.7-inch touchscreen display outline drawing and panel cutout drawing

E1071 (BEPP 64T) 6.5-inch touchscreen display outline drawing and panel cutout drawing

E1101 (BEPP 104T) 10.4-inch touchscreen display outline and panel cutout diagram

E1151 (BEPP 150T) 15 inch touchscreen display outline and panel cutout diagram

Maintenance Requirements

Before maintenance, it is necessary to carefully read the instructions. Only qualified personnel are allowed to operate. Follow the warranty and license agreement. Equipment damage caused by personnel will void the warranty.

Before cleaning or maintenance, disconnect the power supply and use a soft cloth and mild cleaning agent (such as water, isopropanol, or hexane) to clean the display panel and front cover. The battery should be replaced according to the recommended model to prevent explosion. All repaired parts are covered by a 6-month warranty.

Maintenance personnel can perform operations such as back cover replacement, battery replacement, backlight replacement, and complete front cover replacement.

Service and Maintenance Regulations

Only authorized companies are allowed to provide services and repairs. Unauthorized company operations will result in the warranty being invalidated. If training is required, please contact the supplier.

All maintenance must be carried out within the temperature range of 15-30 ° C. The warranty for equipment damage caused by personnel is invalid, and the customer contract takes precedence over the document information.

Disassembly and scrapping requirements

The operation panel or its components must be recycled according to local regulations. Lithium batteries, electrolytic capacitors, displays, and other materials that may pose a risk to health and the environment.

Hardware related content

Hardware Overview

Before the operation panel is launched, it needs to be tested by an independent organization. For example, the E1000 series needs to pass CE, UL and other standard tests. Manufacturers have quality and environmental policy requirements for suppliers and subcontractors.

Hardware Testing

Manufacturers conduct comprehensive hardware testing before obtaining approval for the control panel, with some testing performed by external testing companies such as the Swedish National Testing and Research Institute. All products must pass the testing before leaving the factory.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923