K-WANG

WESTINGHOUSE E510 series compact AC frequency converter

Core identification: Protection level IP20/NEMA 1, compliant with IEC 60018-2-78, UL, cUL, CE, RoHS certification standards.

Application scenarios: covering various motor drive scenarios such as conveyors, mixing equipment, fans, blowers, pumps, lathes, and AC contactor replacements.

WESTINGHOUSE E510 series compact AC frequency converter (VFD)

Product Overview

Product positioning: The E510 series is a compact AC frequency converter (VFD) launched by TECO Westinghouse, featuring miniaturization and easy configuration. It is suitable for motor speed control and can directly replace old VFDs, catering to various needs from simple constant speed scenarios to permanent magnet motor drives.

Core identification: Protection level IP20/NEMA 1, compliant with IEC 60018-2-78, UL, cUL, CE, RoHS certification standards.

Application scenarios: covering various motor drive scenarios such as conveyors, mixing equipment, fans, blowers, pumps, lathes, and AC contactor replacements.

Core technical parameters

Parameter category specific specifications

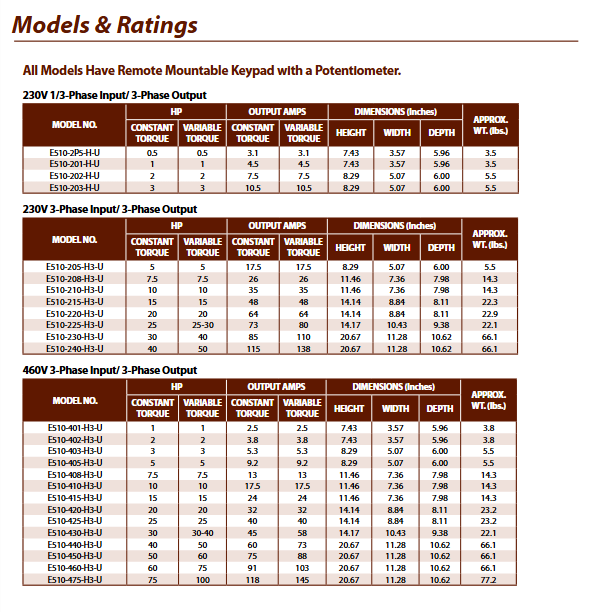

Power range 230V: 0.5-40 HP (1-phase/3-phase input); 460V: 1-75 HP (3-phase input)

Input voltage level 230V: 200-240VAC (+10%/-15%); 460V level: 380-480VAC (+10%/-15%)

Three control modes: V/Hz, sensorless vector (SLV), and permanent magnet sensorless vector (PMSLV)

Frequency Characteristics: Frequency Range: 0-599Hz; Frequency Accuracy: Digital Input 0.01Hz, Analog Input 0.1%

Speed ratio 50:1

Starting torque SLV mode: 150%/1Hz; V/Hz mode: 150%/3Hz

Overload capacity 150% rated output current/1 minute; 120% rated output current/1 minute (5/6 frame)

Carrier frequency 1-16kHz (adjustable)

Functional characteristics

(1) Control and regulation functions

Core control function:

Built in PLC function, supporting simple logic programming.

PID process control loop, including sleep mode, 0-10VDC/4-20mA feedback, and feedback loss detection.

Automatic Voltage Regulation (AVR) can stabilize the output voltage to cope with input voltage fluctuations.

Frequency and speed settings:

Adjustment methods: keyboard potentiometer, external terminal input, 0-10VDC/4-20mA signal, pulse input, up and down key adjustment.

Acceleration and deceleration configuration: 2 sets of acceleration and deceleration time (0-3600 seconds), supporting jog acceleration and deceleration settings and S-shaped slope.

V/Hz characteristics: 18 preset V/Hz curves+user-defined curves, supporting voltage (torque) increase adjustment.

Special functions: Rotating load start, sensorless vector automatic tuning, permanent magnet motor control, DC injection braking, power outage ride through.

(2) Operation and Configuration

Operation interface: 5-digit LED keyboard with speed potentiometer, supporting parameter programming, diagnostic monitoring, and adjustable display.

Parameter management: Parameters are grouped by function for convenient configuration; Support remote keyboard installation (including expansion cable).

Auto run: Supports Auto run mode.

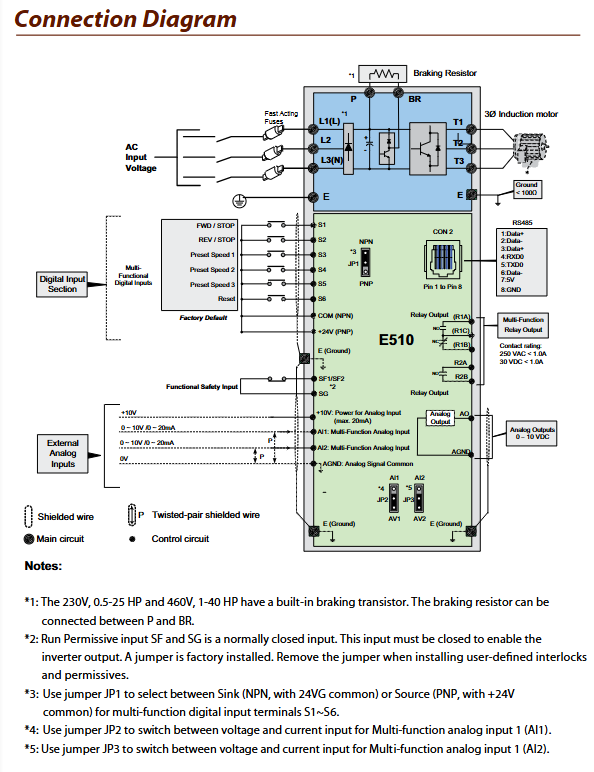

I/O and Communication Interface

(1) I/O interface specifications

Specific configuration of interface type

6-channel configurable digital input, 39 optional functions, supports normally open/normally closed settings, powered by 24V power supply, including pulse input

Digital output with 2 relay outputs, 20 optional functions, supporting normally open/normally closed settings, contact capacity of 250VAC/1A, 30VDC/1A

Analog input with 2 channels, switchable between 0-10VDC or 4-20mA, supports gain and bias adjustment, used for speed reference or PID feedback

Analog output 1 channel 0-10VDC output, 5 configurations (output frequency, set frequency, output current, etc.), supporting gain and bias adjustment

Special safety input for safety input (factory jumper short circuit), cut off the output of the frequency converter when disconnected

Power supply: Built in 24VDC power supply, maximum output current of 60mA; 10V power supply (maximum 20mA), used for external potentiometer power supply

(2) Communication function

Built in RS485 interface, supporting Modbus RTU or BACNet protocols.

Equipped with RJ45 interface and optional USB communication cable (JN5-CM-USB) for PC connection.

Protection features

Specific parameters of protection type

Overload and locked rotor protection support 150%/1-minute overload protection during acceleration, deceleration, and constant speed stages

Overcurrent protection triggered when instantaneous current exceeds 200%

Bus voltage protection overvoltage: 230V input>410VDC, 460V input>810VDC; Undervoltage: 230V input<190VDC, 460V input<380VDC

Other protective grounding faults, phase loss protection, overheating protection, PID feedback loss protection, external fault settings, fire protection mode

Environmental and physical parameters

Environmental adaptability:

Working temperature: -10~+50 ℃; Storage temperature: -20~+70 ℃.

Humidity: ≤ 95% RH (no condensation).

Vibration/impact: 20HP and below 1g (32.2ft/sec ²); 20-25HP 0.6g(19.3ft/sec²)。

Physical dimensions and weight:

230V 1/3 phase input (0.5-3HP): Size 7.43 x 3.57 x 5.96 inches, weight 3.5lbs.

460V 3-phase input (75HP): Size 20.67 × 11.28 × 10.62 inches, weight 77.2lbs.

Standardized terminal design allows for wiring without the need for specialized micro tools.

Model and accessories

(1) Core model classification

Input voltage, input phase, power range, model example

230V 1-phase/3-phase 0.5-3HP E510-2P5-H-U (0.5HP), E510-203-H-U (3HP)

230V 3-phase 5-40HP E510-205-H3-U (5HP), E510-240-H3-U (40HP)

460V 3-phase 1-75HP E510-401-H3-U (1HP), E510-475-H3-U (75HP)

(2) Optional attachments

Attachment Name Model Function

Remote keyboard extension cable JN5-CM-01M/02M/03M/05M extends keyboard installation distance

USB communication cable JN5-CM-USB connects RS485 to PC (USB interface)

LCD operation keyboard JN5-OP-A02 replaces standard LED keyboard, IP20 protection

Parameter copying unit JN5-CU uploads/downloads frequency converter parameters

NEMA 1 protective kit JN5-NK-E01~E04 enhances protection level and is compatible with 1-4 frames

Dust stickers JN5-ECOV1~ECOV4 prevent foreign objects from entering, compatible with 1-4 frames

Key issues

Question 1 (Functional Adaptability): How do the control modes and core functions of E510 frequency converters match different motor drive scenarios?

Answer: E510 provides three control modes that can be adapted to different scenarios: ① Simple constant speed scenarios (such as ordinary fans and pumps): choose V/Hz mode, paired with 18 preset V/Hz curves to meet basic speed control requirements; ② Scenarios with high requirements for starting torque and speed regulation accuracy (such as conveyors and lathes): adopting sensorless vector (SLV) mode, 150%/1Hz starting torque can cope with heavy load starting, and 50:1 speed ratio ensures operational stability; ③ Permanent magnet motor drive scenario (such as high-efficiency energy-saving equipment): Choose permanent magnet sensorless vector (PMSLV) mode, combined with automatic setting function, to fully utilize the energy-saving advantages of permanent magnet motors. At the same time, the built-in PID control can adapt to closed-loop control scenarios (such as pump equipment with pressure and flow control), and the built-in PLC function can simplify external control logic and reduce additional controller configurations.

Question 2 (Selection and Installation): How to adapt the power coverage and physical characteristics of E510 frequency converter to different installation environments, and what parameters should be focused on when selecting?

Answer: There are three key points to focus on when selecting and installing: ① Power and voltage matching: 230V level covering 0.5-40HP (1-phase/3-phase input), suitable for civilian or small industrial scenarios; 460V level covers 1-75HP (3-phase input), suitable for medium and large industrial equipment, and the corresponding model needs to be selected according to the rated power and voltage of the motor; ② Installation space adaptation: The product size ranges from 7.43 × 3.57 × 5.96 inches (low power) to 20.67 × 11.28 × 10.62 inches (high power). The miniaturized design facilitates the renovation and replacement of old equipment, and the corresponding frame size needs to be selected according to the installation space; ③ Environment and Protection: The protection level is IP20/NEMA 1, suitable for indoor dust-free environments. If protection needs to be improved, NEMA 1 kits or dust-proof stickers can be used (note that the current should not exceed 70% of the rated value after sticker installation). At the same time, it must meet the environmental requirements of working temperature -10~+50 ℃ and humidity ≤ 95% RH (no condensation).

Question 3 (Expansion and Maintenance): How do the I/O interfaces, communication functions, and accessories of the E510 frequency converter support system integration and post maintenance?

Answer: ① I/O expansion: 6 configurable digital inputs (39 functions), 2 relay outputs (20 functions), and 2 analog inputs/outputs, which can flexibly interface with external devices such as sensors, actuators, buttons, etc., to meet complex control logic requirements; ② Communication integration: Built in RS485 interface (Modbus RTU/BACNet), supports communication with upper computers such as PLC and touch screen, optional USB cable for PC parameter configuration, facilitating centralized system control; ③ Maintenance convenience: equipped with LED keyboard (supports remote installation), can directly program parameters and diagnose faults; Optional LCD keyboard and parameter copying unit, simplifying the unified configuration of parameters for multiple devices; The NEMA 1 kit and dust stickers are standard accessories for easy replacement and maintenance in the future, ensuring long-term stable operation of the equipment.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923