K-WANG

YOKOGAWA EJA110E Diff erential Pressure Transmitter

Signal output: default output 4-20mA DC analog signal, and supports BRAIN/HART digital communication overlay; There are also FOUNDATION Fieldbus, PROFIBUS PA, and 1-5V DC (low-power HART) protocols available.

Additional functions: capable of synchronously measuring static pressure, static pressure data can be displayed on integrated indicators or remotely monitored through communication; Equipped with fast response, remote parameter setting, and self diagnostic functions, some models (except for Fieldbus, PROFIBUS, and low-power models) comply with SIL 2 safety certification, and dual transmitter configuration can meet SIL 3 requirements.

YOKOGAWA EJA110E Diff erential Pressure Transmitter

Product Core Overview

1. Core functions and applications

Measurement object: It can accurately measure the flow rate of liquids, gases, and vapors, as well as the liquid level, density, and pressure.

Signal output: default output 4-20mA DC analog signal, and supports BRAIN/HART digital communication overlay; There are also FOUNDATION Fieldbus, PROFIBUS PA, and 1-5V DC (low-power HART) protocols available.

Additional functions: capable of synchronously measuring static pressure, static pressure data can be displayed on integrated indicators or remotely monitored through communication; Equipped with fast response, remote parameter setting, and self diagnostic functions, some models (except for Fieldbus, PROFIBUS, and low-power models) comply with SIL 2 safety certification, and dual transmitter configuration can meet SIL 3 requirements.

2. Core Technology Highlights

Adopting monocrystalline silicon resonant sensors, it combines high precision and stability, can adapt to complex industrial environments, and supports multiple communication protocols and security certifications, adapting to industrial scenarios with different security levels.

Standard specifications

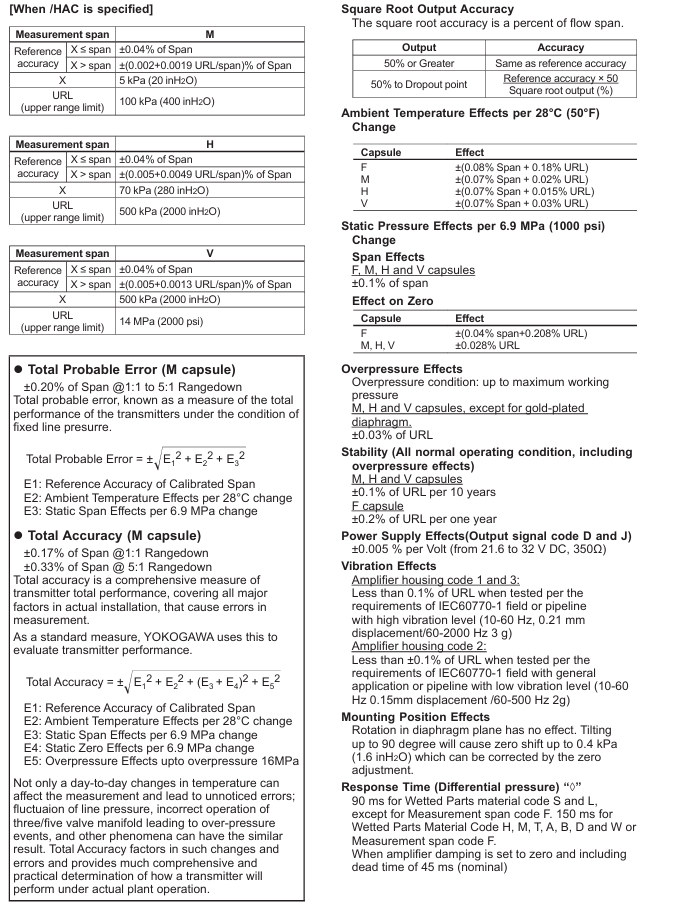

1. Range and span limitations (differentiated by capsule type)

Different capsule types (F, L, M, H, V) correspond to different measurement spans and ranges, covering multiple pressure units (kPa, inH ₂ O, mbar, mmH ₂ O, kgf/cm ², MPa, psi, bar). The following are examples of key parameters:

Capsule type applicable scenarios span range (example: kPa) range range (example: kPa)

F Wet end Material Code S Special 0.5-5-5

L Wet end material code is not S specific 0.5-10-10

M universal medium and low voltage 1-100-100-100

H medium high voltage 5-500-500-500

V high pressure 0.14-14MPa (140-14000kPa) -0.5-14MPa (-500-14000kPa)

2. Performance specifications

(1) Benchmark accuracy (including linearity, hysteresis, and repeatability)

Accuracy calculation is divided into two scenarios: "X ≤ span" and "X>span" (where X is a specific pressure threshold, such as F capsule X=2kPa). The accuracy formula varies for different capsule types, as shown in the following example:

Capsule type X threshold (kPa) accuracy formula (X ≤ span) accuracy formula (X>span)

F 2 ± 0.055% span ± (0.005+0.02 x URL/span)% span

M 5 ± 0.055% span ± (0.005+0.0025 x URL/span)% span

H 100 ± 0.055% span ± (0.005+0.01 x URL/span)% span

V 1400 (1.4MPa) ± 0.055% span ± (0.005+0.005 × URL/span)% span

Note: URL is the upper limit range value, such as F capsule URL=5kPa

If the/HAC high-precision option is specified, the accuracy of some capsules (M, H, V) can be improved. For example, when M capsule X ≤ span, the accuracy can reach ± 0.04% span.

(2) Comprehensive error index

Total possible error (M capsule): Considering the benchmark accuracy (E1), environmental temperature influence (E2, every 28 ℃ change), and static pressure span influence (E3, every 6.9MPa change), the formula is ± E 12+E 22+E 32, and the span is ± 0.20% under the range ratio of 1:1 to 5:1.

Total accuracy (M capsule): additionally taking into account the effects of static pressure zero point (E4) and overpressure (E5), the formula is ± E 12+E 22+(E 3+E 4) 2+E 52, with a span of ± 0.17% under a 1:1 range ratio and ± 0.33% under a 5:1 range ratio.

(3) Other environmental impacts

Temperature effect: For every 28 ℃ change, the F capsule error is ± (0.08% span+0.18% URL), and the M/H/V capsule error is ± (0.07% span+0.02%/0.015%/0.03% URL).

Static pressure effect: For every 6.9MPa change, the span error of all capsules is ± 0.1% span; Zero point error F capsule ± (0.04% span+0.208% URL), M/H/V capsule ± 0.028% URL.

Stability: M/H/V capsules have a ± 0.1% URL every 10 years, while F capsules have a ± 0.2% URL every year.

Functional specifications

1. Signal output and alarm

Output type, signal range, fault alarm mode

4-20mA HART/BRAN 3.6-21.6mA upper limit alarm: ≥ 21.6mA (110%), lower limit alarm: ≤ 3.2mA (-5%)

1-5V HART (low power consumption) 0.9-5.4V upper limit alarm: ≥ 5.4V (110%), lower limit alarm: ≤ 0.8V (-5%)

2. Operation and monitoring functions

Damping time: 0.00-1000s software adjustable, please note that damping<0.5s under the BRAN protocol may affect communication stability.

Integrated indicator (optional): 5-digit numerical display+6-digit unit display+bar chart, can cyclically display differential pressure, differential pressure percentage, scale differential pressure, and static pressure.

Self diagnosis: It can detect CPU faults, hardware faults, configuration errors, differential pressure/static pressure/capsule temperature exceeding the range, and supports user-defined differential pressure/static pressure high and low alarms.

Physical and Environmental Specifications

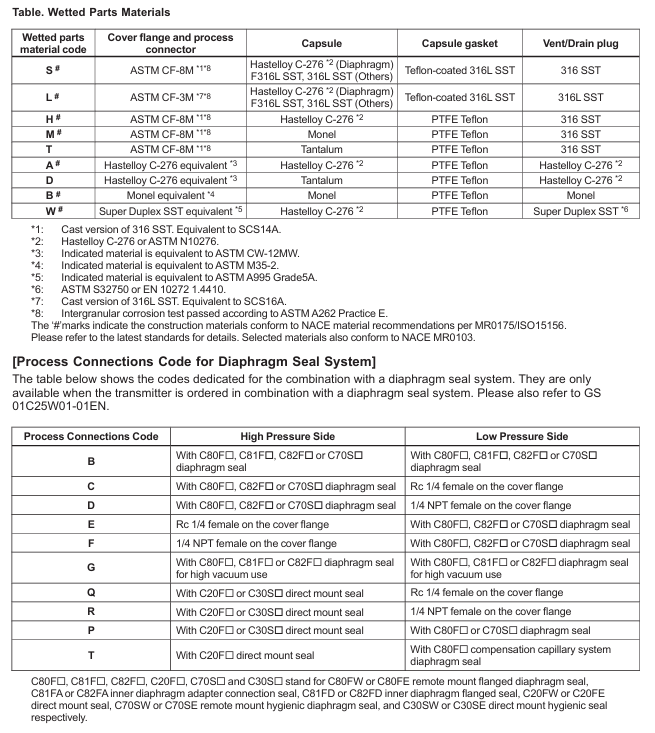

1. Material

Wet end materials: distinguished by codes (S, L, H, M, T, A, D, B, W), such as S code containing ASTM CF-8M flange and Hastelloy C-276 diaphragm; Sealing gaskets are commonly made of PTFE or fluororubber.

Non wetted material: The shell is made of low copper cast aluminum alloy (optional stainless steel), coated with polyester powder (mint green) or epoxy polyurethane (optional), and the bolts are made of B7 carbon steel, 316L stainless steel, etc.

2. Environmental adaptability

Temperature: ambient temperature -40-85 ℃ (-30-80 ℃ with LCD), process temperature -40-120 ℃.

Humidity: 0-100% RH.

Protection level: IP66/IP67, Type 4X.

Pressure resistance: The maximum working pressure (MWP) is 16MPa, and the/HG option can reach 25MPa; Blasting pressure of 69MPa (S material non F range) or 47MPa (other materials/F range).

3. Installation and Connection

Installation method: Supports vertical pipelines (left high-pressure connection), horizontal pipelines (left/right high-pressure connection), bottom connections, etc., and requires corresponding installation codes (7, 8, 9, U, B, etc.).

Process connection: Optional Rc1/4, Rc1/2, 1/4 NPT, 1/2 NPT and other interfaces, or no connector (flange with internal thread).

Electrical connection: Supports G1/2, 1/2 NPT, M20 and other interfaces, with 1-2 connection ports and blind plugs (optional stainless steel blind plugs).

Selection and optional specifications

1. Model suffix code (core selection dimension)

Example explanation of selection dimension code

The output signals D (BRAN), J (HART 5/7), and Q (1-5V HART) determine the communication protocol and signal type

Capsule types F, L, M, H, V determine the range of measurement

Wet end materials S, L, H, M, etc. are suitable for different corrosive media

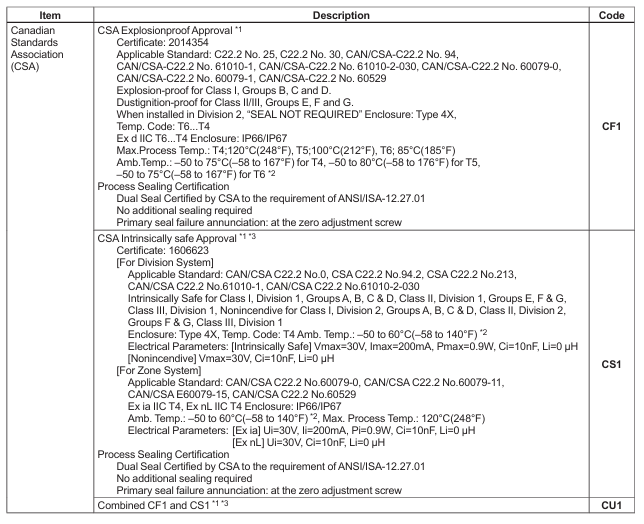

Explosion proof certification FF1 (FM explosion-proof), KS21 (ATEX intrinsic safety), CF1 (CSA explosion-proof) and other suitable for hazardous environments

2. Key optional functions

High precision (HAC): Improve the accuracy of M/H/V capsules.

High pressure structure (HG): MWP increased to 25MPa.

Lightning protection (A): Maximum withstand current of 6000A (1 × 40 μ s).

Anti corrosion treatment (X2/HC): epoxy coating or 316 stainless steel external parts.

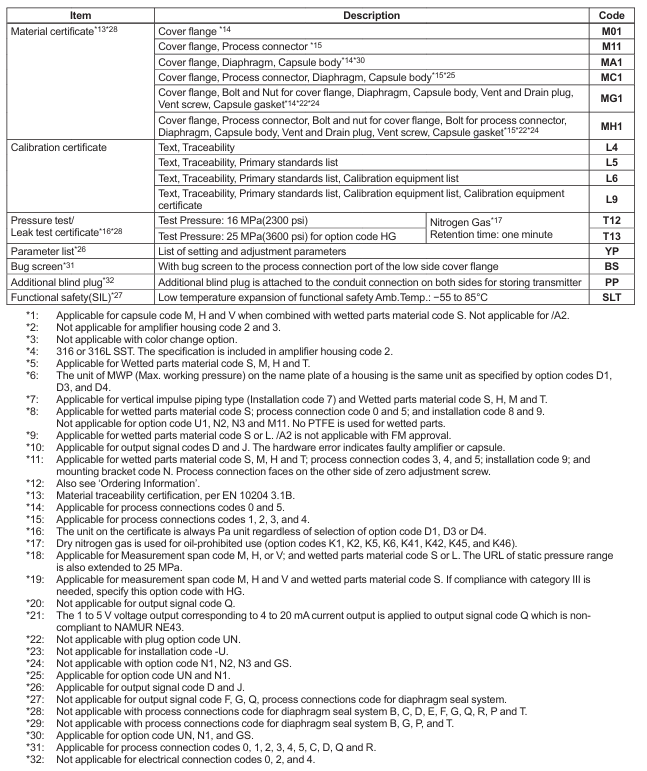

Certificate type (L4/L5/L6/L9): Provide calibration certificates (including traceability, standard list, etc.).

Installation and ordering information

1. Installation points

Size: Different installation methods (vertical/horizontal/bottom/universal flange) correspond to different sizes (unit: mm/inch), please refer to the dimension diagram in the document, for example, the total length of the vertical pipeline type is about 223-256mm.

Wiring: 4-20mA type needs to distinguish between power/output terminals and external indicator terminals; The 1-5V type requires distinguishing between power terminals and signal terminals, and supports 3-4 wire connections.

2. Clear information required for ordering

Model, suffix code, and option code.

Calibration range (LRV/URV, -32000 to 32000, LRV needs to be 0 for square root output) and units (such as kPa, psi).

Output mode (linear/square root) and display mode.

The display scale of the integrated indicator (0-100% or custom range).

HART protocol version (choose 5 or 7 for J code).

Tag (TAG NO: 16/22 characters; Software Tag: 32 characters, HART 7 supports long tags).

Compliance and Reference

Compliance standards: EMC complies with EN 61326-1 Class A, pressure equipment complies with EU 2014/68/EU (PED), RoHS complies with EN IEC 63000.

Reference documents: Fieldbus specifications refer to GS01C31T02-01EN, PROFIBUS PA refers to GS01C31T04-01EN, functional safety data refers to TI01C25A05-01EN/21EN.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector