K-WANG

Foxboro ™ I/A Series FBM222 Analog Input Module

Foxboro ™ I/A Series FBM222 Analog Input Module

Product Overview and Core Positioning

FBM222 is a 16 channel highly integrated analog input module with core functionality for Foxboro ™ The I/A Series distributed control system (DCS) collects 4-20mA analog signals on site (supporting two-wire/three wire transmitters), while using HART ® The protocol (digital communication superimposed on 4-20mA signal) enables bidirectional data exchange with on-site devices (such as reading device diagnostic information and configuring parameters). It is positioned as a "high-density, high reliability analog signal+HART digital signal integrated acquisition center", suitable for the needs of batch collection of sensor/transmitter data in industrial scenarios such as petroleum, chemical, and power.

1. Core functions and compatibility

Dual compatibility of signals: All 16 channels support "4-20mA analog signal" and "HART ® Digital signals "can be mixed and connected to different types of on-site devices (without the need for additional hardware switching).

HART communication capability: As a HART host, it supports HART protocol v5/v6/v7 version devices and can execute HART universal commands, common commands, and device specific commands (with Field Device Expert for HART tool), but does not support HART burst mode.

Basic adaptation requirements: It is necessary to use I/A Series software v8.2-v8.8 or Control Core Services (CCS) v9.0 or above, and connect to the Fieldbus communication module (FCM) or control processor (FCP) through a redundant 2Mbps fieldbus to achieve data upload and instruction issuance.

Power supply flexibility: Supports "internal module power supply" (providing 24VDC power supply for two-wire transmitters) or "external independent power supply" (compatible with three wire devices), and signal crosstalk needs to be suppressed through Cable Balun modules when external power is supplied.

Key features and technological advantages

1. Core Features

Specific description of characteristic categories

Full isolation protection achieves triple isolation: 16 channels are isolated from each other, channels are isolated from module logic circuits, and channels are isolated from ground. It can withstand 600VAC common mode voltage for 1 minute (without damage), completely avoiding signal interference and equipment burnout risks.

High precision acquisition adopts Sigma Delta (∑ - Δ) analog-to-digital converter, with a data update cycle of 100ms per channel. The accuracy of analog acquisition meets the industry's high standards, meeting the requirements of process control for real-time and accurate data.

The harsh environment adaptation shell is made of extruded aluminum material, which meets the Class G3 (harsh industrial environment) requirements of ISA S71.04 standard. It can withstand complex scenarios such as dust, humidity fluctuations (5% -95% non condensing), and sudden temperature changes (-20~70 ℃).

Hot swappable and easy to maintain support "with hot swappable", allowing for module replacement without disconnecting field wiring, power supply, or communication bus; The front of the module is equipped with LED indicator lights (running status, bus activity, channel communication status), which can intuitively locate faults.

Communication redundancy ensures access to a redundant 2Mbps fieldbus (A/B dual path), which automatically switches to the backup path in case of a single path failure without communication interruption, ensuring data collection continuity.

2. Special component: Cable Balun module

When multiple channels are powered by an external common power source, a Cable Balun module is required to maintain the balance of the HART communication line and prevent near end crosstalk (this component is not required for internal power supply channels). The core parameters are as follows:

Specific specifications of component information

Model CBM-4

Part number RH903SV

Each module contains 4 Balun units (1 unit corresponds to 1 external power supply circuit), with a maximum increase of 30 Ω in circuit resistance to suppress signal interference

If the hazardous environment adaptation is used in hazardous areas (such as Zone 2), it is necessary to use intrinsic safety barriers (such as MTL 787S+) to limit the energy of the line; External power sources can be connected in parallel with redundant power sources. It is recommended to use capacitors to filter out AC interference

Functional and Performance Specifications

1. Signal and communication parameters

Parameter category specific specifications

HART device compatibility supports HART ® On site devices for protocol v5, v6, and v7 versions

Internal power supply of input resistor (including terminal components): 302 Ω; External power supply: 282 Ω

Internal power supply output 24VDC ± 10%, output impedance 20 Ω (including terminal components), single channel current limit < 37mA (anti overcurrent)

Fieldbus communication redundancy of 2Mbps, bidirectional communication with FCM/FCP, with a maximum communication distance of 1.2km (without repeaters)

Channel capacity of 16 independent analog input channels, supporting mixed access of two-wire/three wire devices

2. Power supply and power consumption

Power parameter specifications

Input voltage 24VDC (redundant power supply), allowing+5%/-10% fluctuation

Maximum power consumption 10.8W

Maximum heat dissipation 7.2W

3. Calibration requirements

The precision calibration of the module and supporting terminal components (TA) has been completed at the factory, and there is no need for regular on-site calibration, greatly reducing maintenance workload (only confirming basic parameters after module failure replacement).

Hardware and installation specifications

1. Core hardware components

Component type, model/part number, key parameters

FBM222 module RH927AJ weight: approximately 340g (12oz); Dimensions: Height 102mm x Width 114mm (including installation ears) x Depth 104mm

Terminal component (TA) RH924JH material: polyamide (PA, temperature resistance -20~70 ℃); Wiring type: compression terminal; Weight: Approximately 181g (0.40lb); Adapt to 16 channel signal access

Terminal cables are divided into two types of materials:

-Polyurethane/PVC (Type 1 P/PVC): suitable for conventional industrial environments;

-Low Smoke Zero Halogen (Type 1 LSZH): Suitable for scenarios with requirements for smoke toxicity and corrosiveness (such as subways, data centers)

Cable interface module side: 37 pin D-subminiature (D-type) interface; TA side: 25 pin D-subminiature interface

2. Installation requirements

Specific requirements for installation category

The module installation needs to be installed on a 200 series standard modular base plate (such as RH101KF), which supports horizontal/vertical DIN rail installation or can be adapted to a 19 inch rack through an installation kit; Can be installed on the same substrate as other 200 series FBM modules

TA can be installed independently on 32mm or 35mm DIN rails, and can be installed in the same cabinet or adjacent cabinets with the module (the terminal cable supports a maximum length of 30m)

The wiring specifications support solid/multi strand wires (wire diameter 0.2~4mm ²/24~12AWG), and multi strand wires with wire ears (wire diameter 0.2~2.5mm ²) can also be adapted

Environmental and Compliance Certification

1. Environmental parameters

Environment category, operating conditions, storage conditions

Temperature -20~70 ℃ (-4~158 ℉) -40~70 ℃ (-40~158 ℉)

Relative humidity 5%~95% (no condensation) 5%~95% (no condensation)

Altitude operation: up to 3000m; storage: -300~12000m

The anti pollution level complies with ISA S71.04 Class G3 and has passed the EIA 364-65A Class III mixed gas exposure test (withstanding a corrosive environment for 10 years)

Anti vibration 0.75g (frequency 5-500Hz)-

2. Compliance certification

Specific standards for certification categories

Electromagnetic compatibility (EMC) complies with EU Directive 2014/30/EU, EN 61326-1:2013 Class A (Emission and Industrial Immunity)

Product Safety - USA/Canada: UL/UL-C certification, applicable to Class I A-D Group 2, T4 temperature code cabinet systems;

-EU: Low Voltage Directive 2014/35/EU, ATEX Directive 2014/34/EU (DEMKO certified Ex nA IIC T4, suitable for Zone 2 hazardous environments)

International Safety IECEx Certification (compliant with IEC 60079 series standards)

Environmental compliance complies with the EU RoHS Directive 2011/65/EU and revised versions 2015/863, 2017/2102 (restricting the use of hazardous substances)

California Proposition 65 products contain lead and lead compounds, which may cause cancer or reproductive harm. For more information, please refer to www.P65Warning.ca.gov

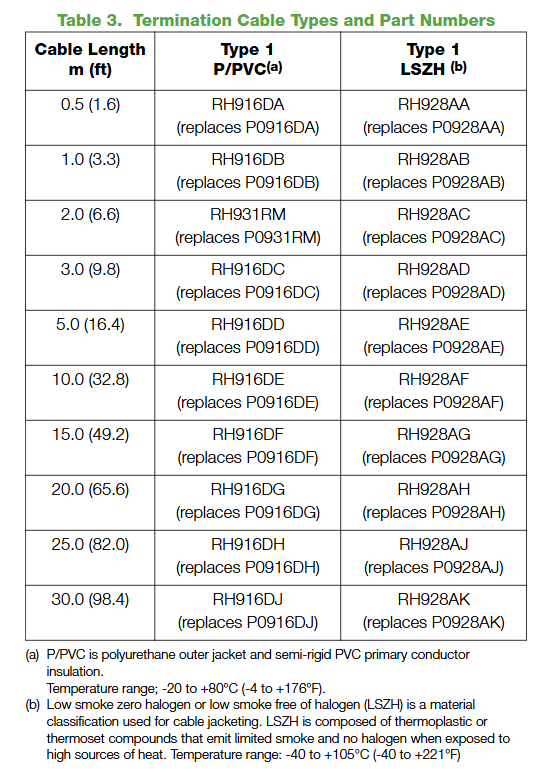

Terminal Cable Selection Table

Terminal cables are classified by material and length, and commonly used specifications are as follows (can cover installation distances of 0.5-30m):

Length (m/ft) Type 1 Polyurethane/PVC Cable (Part Number) Type 1 Low Smoke Zero Halogen (LSZH) Cable (Part Number)

0.5/1.6 RH916DA RH928AA

1.0/3.2 RH916DB RH928AB

2.0/6.6 RH931RM RH928AC

3.0/9.8 RH916DC RH928AD

5.0/16.4 RH916DD RH928AE

10.0/32.8 RH916DE RH928AF

15.0/49.2 RH916DF RH928AG

20.0/65.6 RH916DG RH928AH

25.0/82.0 RH916DH RH928AJ

30.0/98.4 RH916DJ RH928AK

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923