K-WANG

Foxboro FBM224 Modbus ® communication module

Foxboro FBM224 Modbus ® communication module

Module core positioning and core value

1. Core positioning

FBM224 is a product specifically designed for Foxboro Evo ™ Process Automation System and I/A Series ® The core function of the Modbus master communication interface module in system design is to build a communication bridge between Modbus slave devices (such as PLCs, field I/O devices, and smart meters) and system control processors (FCP280, FCP270/ZCP270, CP60), achieving seamless integration of device data from different vendors with the Foxboro system control database.

2. Core values

Multi protocol and multi interface compatibility: Supports RS-232, RS-422, and RS-485 communication interface standards simultaneously, adapting to the communication needs of the vast majority of Modbus slave devices without the need for additional converters;

Flexible redundancy deployment: supports port redundancy configuration (1&2 ports, 3&4 ports can be combined into logical redundancy ports), adapts to dual port Modbus devices, and improves communication link reliability;

Large capacity data exchange: A single module can connect to 64 Modbus slave devices, support 2000 DCI data connections, and can cover up to 32000 digital I/O points, meeting the data transmission needs of medium to large industrial scenarios;

Adaptation to hazardous environments: With the use of specialized terminal components (TA), it can be installed in Class I, Division 2, and Zone 2 hazardous areas, suitable for high-risk industries such as petrochemicals and natural gas;

Plug and play and easy maintenance: supports hot swappable design, module replacement does not require disconnecting on-site wiring, power and communication cables, reducing the risk of system shutdown.

Hardware composition and physical characteristics

(1) Core hardware structure

1. Module body

Shell material: Made of sturdy extruded aluminum alloy shell, it has both physical protection and electrical shielding functions, and can resist vibration, impact, and electromagnetic interference in industrial sites;

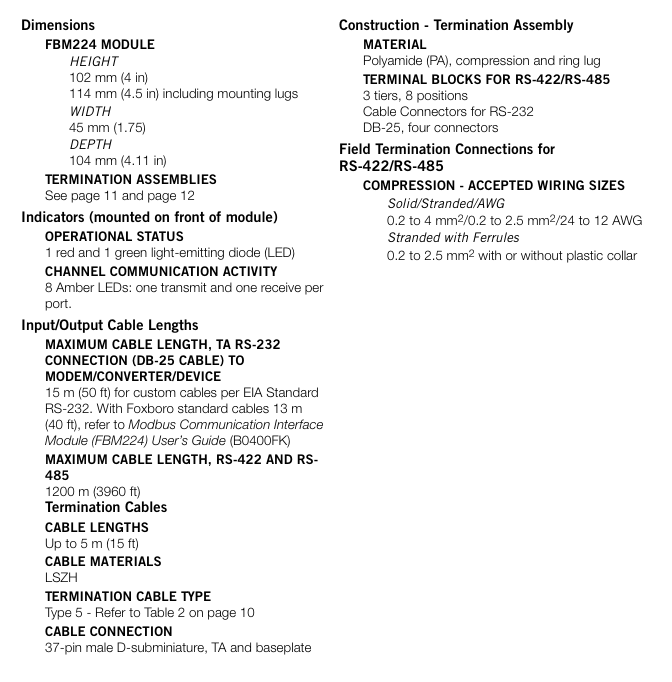

Size specifications: Height 102mm (including installation ears 114mm) x Width 45mm x Depth 104mm, Weight approximately 284g (10oz), in compliance with the Compact 200 Series module standard size, suitable for modular base plate installation;

Status indicator lights: The front integrates 10 LED indicator lights, including 1 red (fault) and 1 green (running) status light, as well as 8 amber communication lights (1 transmitter light and 1 receiver light per port), providing real-time feedback on the module's operating status and port communication activity.

2. Terminal Component (TA)

As the wiring hub between modules and field devices, TA has the following core designs:

Installation method: Supports 32mm or 35mm DIN rail installation, suitable for industrial standard installation scenarios;

Wiring interface:

RS-232: 4 standard DB-25 male connectors, each port is equipped with 24 DIP switches, and RS-232 signal pins can be flexibly configured (such as Clear to Send and Request to Send interconnection);

RS-422/RS-485: Three layer compression or ring terminal block, supporting 0.2-4mm ² solid/multi strand wires (24-12 AWG), suitable for on-site wiring of different wire diameters;

Key function: Built in switchable terminal resistors for each port (used for RS-422/RS-485 bus matching), reducing signal reflection interference; The material is polyamide (PA), which combines temperature resistance and mechanical strength;

Size and weight: Compressed TA length 216mm, weight 320g; Circular wiring TA length 250mm, weight 454g, can be selected according to on-site wiring requirements.

3. Connect the cable

Terminal cable: used for the connection between TA and modular base plate, using 37 pin D-subminiature male head, made of low smoke and halogen-free (LSZH) material, supporting four lengths of 1.0m, 2.0m, 3.0m, 5.0m (corresponding to models RH928AW/AZ, etc.), with a maximum extension of 5m (16 feet), suitable for different installation distance requirements;

On site communication cable:

RS-232: Following EIA standards, custom cables can be up to 15m (50 feet) long, while Foxboro standard cables can be up to 13m (40 feet) long;

RS-422/RS-485: Using shielded twisted pair cables, the longest communication distance can reach 1200m (3960 feet), meeting the requirements of long-distance distributed deployment.

(2) Installation and deployment features

1. Bottom plate installation

The module needs to be installed on the Foxboro modular base plate, which supports 4-slot or 8-slot FBM installation. It can be installed horizontally/vertically on DIN rails or on a 19 inch rack (with accompanying installation kit); The bottom board integrates FBM signal connectors, redundant 24V DC power interfaces, and I/O cable interfaces to ensure stable power supply and signal transmission of the module.

2. Hot swappable design

Modules can be directly plugged and replaced without the need to disassemble on-site equipment wiring, power cables, or communication cables, significantly reducing maintenance downtime and improving system availability.

Communication function and protocol support

1. Modbus protocol adaptation

Working mode: only supports Modbus RTU mode (asynchronous communication), does not support ASCII mode;

Function code support: Covering commonly used core industrial function codes to meet all data reading and writing requirements, as follows:

Function code function description application scenario

01 Read coil status, read digital output status (such as valve switch, indicator light status)

02 Read input status Read digital input status (such as sensor trigger signals, equipment fault feedback)

03 Read and hold registers to read device configuration parameters, cumulative data, etc. (such as cumulative flow rate of flow meters)

04 Read input register to read real-time measurement data (such as analog conversion values of temperature, pressure, and flow)

05 Mandatory single coil control for single digital output (such as starting/stopping motors, opening/closing valves)

06 Preset single register configuration device for individual parameters (such as setting pressure threshold, flow upper limit)

Self check the communication link between the 08 circuit diagnostic testing module and the slave device to troubleshoot connection faults

15. Mandatory batch control of multiple digital outputs with multiple coils (such as simultaneously starting a group of devices)

16 preset multi register batch configuration of device parameters (such as batch setting of measurement ranges for multiple instruments)

Data format: Supports 8-bit characters, configurable parity check (odd check/even check/no check), configurable stop bit (1 bit/2 bits), adaptable to communication parameter settings of different slave devices.

2. Port configuration and communication capability

(1) Port characteristics

The module is equipped with four independent serial communication ports, each of which can be individually configured as an RS-232, RS-422, or RS-485 interface without the need for hardware modification. Switching can be completed through software configurator;

Port redundancy function: Ports 1&2 and 3&4 can be configured as a single logical port, and can be connected to dual port Modbus devices with redundant cables to achieve communication link redundancy and avoid data interruption caused by single point failures.

(2) Communication parameters

Transmission rate: Supports 10 speeds including 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, and 115200 baud, and can be flexibly selected according to communication distance and device requirements (low-speed is recommended for long-distance communication, high-speed is recommended for short distance high-speed transmission);

From device address: Supports a range of 1-247 addresses, which can cover the addressing requirements of Modbus devices in the vast majority of industrial scenarios.

3. Data interaction capability

(1) Access capacity

A single module can support up to 64 Modbus slave devices (the actual number is affected by device type, data volume, and scanning rate);

A single module can support up to 2000 distributed control interface (DCI) data connections, covering:

2000 analog I/O values (integer or IEEE single precision floating-point type);

32000 digital I/O values (calculated by packing 32 digital points per connection);

Mixed analog and digital data connection.

(2) Data processing and updating

As a Modbus master, the module periodically polls the input data from the device according to the user configured scanning rate, and the output request is immediately executed after being sent by the control processor, without being limited by the polling cycle;

The access speed of the control station to FBM224 data can reach up to 500ms at the fastest, with low data update latency, meeting real-time control requirements;

Support data format conversion: The module automatically converts raw data from the device (2-byte/4-byte signed/unsigned integers, 4-byte IEEE floating point types, binary values) into Foxboro system compatible format and stores it in the system database for use by plant management functions and operator interfaces; Simultaneously supporting byte order and bit order switching, adapting to data storage formats of devices from different manufacturers.

Configuration tools and operating procedures

1. Configuration tool

Provide Windows ® Compared to Solaris ® There are two versions of configurator for operating systems, namely port configurator and device transaction configurator. During the configuration process, the validity of parameters (such as rate range and address legality) is automatically verified to avoid configuration errors.

(1) Port configurator

Used to set communication parameters for each port, including:

Communication interface standard (RS-232/RS-422/RS-485);

Transmission rate, parity check, stop bit;

Enable/disable port redundancy mode (1&2 ports, 3&4 ports).

(2) Device Transaction Configurator

Used to set communication transaction parameters for slave devices, including:

Scanning rate: configurable from 0.5 seconds to 255 seconds, default 500ms, adjustable according to device response speed and real-time data requirements;

Phase setting: When the scanning rate is an integer multiple of the base period, specify the specific scanning period to distribute the communication load between the module and the device;

Transaction details: Function code, starting address of data, amount of data transmitted in a single transaction, up to 64 independent transaction configurations supported by a single device.

2. Control block support

The module is compatible with Foxboro standard DCI control block types, through Foxboro Evo Control Editors、I/A Series Configuration Component(IACC)、Integrated Control Configurator(ICC) Or FoxCAE ™ The software is configured in the control processor, and the control block interacts with Modbus slave devices for data read and write through address mapping. The supported types of control blocks are as follows:

Function description of control block type

BIN binary input

BINR redundant binary input

BOUT binary output

IIN integer input

IOUT integer output

PAKIN packaging input (multi digit point packaging)

PAKOUT packaging output (multi digit point packaging)

PLSOUT pulse output

RIN Real Input (Floating Point Type)

RINR redundant real number input

ROUT Real Output (Floating Point Type)

Core performance parameters and environmental adaptability

1. Electrical performance

Power requirements: Redundant 24V DC power supply, voltage range+5%~-10% (i.e. 21.6V~25.2V DC), maximum power consumption 7W, maximum heat dissipation 7W, compatible with Foxboro standard redundant power supply (such as FPS480-24);

Channel isolation: Galvanic isolation is used between each communication channel and ground, which can withstand 600V AC voltage for 1 minute without damage, effectively avoiding ground loop interference and high voltage intrusion;

Fieldbus communication: Communicate with FCM (fieldbus communication module) or control processor through redundant 2Mbps module fieldbus, support A/B dual path switching, automatically switch to another path when one path fails, ensuring communication continuity.

2. Environmental adaptability

(1) Temperature and humidity

Module operating temperature: -20 ℃~+60 ℃ (-4 ℉~+140 ℉);

Terminal component operating temperature: -20 ℃~+70 ℃ (-4 ℉~+158 ℉);

Storage temperature: -40 ℃~+70 ℃ (-40 ℉~+158 ℉);

Relative humidity: 5%~95% (non condensing), suitable for industrial environments with high humidity and large temperature differences.

(2) Anti interference and protection

Electromagnetic Compatibility (EMC): Complies with the European EMC Directive 2004/108/EC, EN61326:2013 Class A emission standards and industrial immunity levels, including:

Electrostatic discharge (ESD): Contact 4kV, air 8kV;

Radiated field immunity: 10V/m at frequencies of 80-1000MHz;

Electric fast transient/pulse group: I/O, DC power supply and communication line 2kV;

Surge immunity: ± 2kV for AC/DC power lines, ± 1kV for I/O and communication lines;

Pollution level: Compliant with ISA S71.04 Class G3 (harsh environment) standard, resistant to industrial dust, oil pollution and other pollution;

Vibration and impact: Can withstand vibrations of 7.5m/S ² (0.75g) and 5-500Hz, suitable for the vibration environment generated by industrial field equipment operation.

Security certification and compliance

The module is certified through multiple regions and standards to ensure compliant use in different countries/regions and hazardous environments

Specific standards and instructions for certification types

Electrical Safety (US Canada) UL/UL-C certification, applicable to Class I, Groups A-D; Division 2; T4 temperature group shell system; As an associated device, provide non flammable communication circuits for Class I, Groups A-D hazardous areas; Meets the Class 2 circuit requirements of the National Electrical Code (NFPA 70 Article 725) and the Canadian Electrical Code (CSA C22.1 Section 16)

European certification for Low Voltage Directive 2006/95/EC and Explosion proof Directive 94/9/EC; DEMKO certification for EEx nA IIC T4, suitable for Zone 2 hazardous areas, as an associated device providing non flammable on-site circuits for Zone 2, Group IIC potentially explosive environments

Environmental compliant terminal components (TA) and terminal cables comply with the EU RoHS Directive 2002/95/EC and revised 2011/65/EU, restricting the use of harmful substances such as lead and mercury

Electromagnetic compatibility complies with CISPR 11 Industrial, Scientific, and Medical (ISM) Radio Frequency Equipment Electromagnetic Disturbance Limits, IEC 61000 series immunity standards (static electricity, radiation, surge, etc.)

Typical application scenarios and topology configuration

1. Applicable industries and scenarios

Core industries: petrochemical, natural gas, power, water treatment, manufacturing (such as automobiles, electronics) and other industrial fields that require multi device interconnection;

Typical applications:

Data exchange between PLCs from different manufacturers and Foxboro systems (such as connecting equipment status data from third-party PLCs to the Foxboro operator interface);

Intelligent instruments (such as flow meters, pressure transmitters) data acquisition (reading instrument measurement values through Modbus RTU);

Distributed I/O device control (controlling the output ports of remote I/O modules through Modbus commands);

Communication of hazardous area equipment (such as safety communication between sensors and systems in Zone 2 of the petrochemical industry).

2. Typical topology configuration

The module supports multiple Modbus network topologies and adapts to different on-site layout requirements. The core configuration is as follows:

(1) Redundant link configuration

Topology: Ports 1 and 2 are configured as redundant logical ports, while ports 3 and 4 are configured as redundant logical ports. They are respectively connected to dual port Modbus slave devices or to redundant links of single port devices through redundant cables;

Advantages: Avoiding data interruption caused by a single communication link failure, improving system reliability, and suitable for critical control circuits.

(2) Mixed interface configuration

Topology structure: Four ports are configured as different interfaces (such as one port for RS-232 connection to a modem, two ports for RS-422 direct connection to devices, and three&four ports for RS-485 multi-point bus connection to multiple instruments);

Advantages: Devices that can adapt to multiple communication interfaces simultaneously, without the need for additional interface converters, reducing system complexity.

(3) Remote distributed configuration

Topology structure: Multiple slave devices (such as flow meters and pressure sensors deployed along pipelines) are connected on a single bus through the 1200m long-distance transmission capability of RS-485 interface. The modules are deployed in the control room and the on-site devices are installed in a distributed manner;

Advantages: Reduce on-site wiring costs, simplify construction difficulties, and adapt to large-scale industrial scenarios.

Key selection and deployment considerations

1. Key selection points

Confirm the communication interface (RS-232/RS-422/RS-485) and Modbus mode (RTU mode required) of the device;

Determine whether the module capacity meets the requirements based on the number of devices (≤ 64) and data points (≤ 2000 DCI connections);

In hazardous environments, it is necessary to confirm the installation area level (Class I, Division 2 or Zone 2) to ensure that the module matches the certification of the TA;

When the communication distance exceeds 15m (RS-232) or requires multi-point connection, RS-485 interface is preferred.

2. Deployment precautions

Wiring specification: RS-422/RS-485 requires shielded twisted pair cables, and terminal resistors (configured through TA's DIP switch) should be enabled at both ends of the bus to avoid signal reflection; RS-232 wiring needs to match the device pin definition (adjusted through TA's DIP switch);

Power configuration: It is recommended to use redundant power supply in key scenarios to avoid module shutdown caused by power failure;

Electromagnetic interference protection: Modules and cables should be kept away from strong electromagnetic interference sources such as frequency converters and motors, and the shielding layer should be grounded at one end to reduce interference effects;

Software compatibility: Ensure that the control system software version meets the requirements (I/A Series v8.8+or Foxboro Evo v9.0+) to avoid incompatibility between configuration tools and the system.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923