K-WANG

Endress+Hauser Prosonic T FMU30 Ultrasonic Liquid Level Measuring Instrument

Endress+Hauser Prosonic T FMU30 Ultrasonic Liquid Level Measuring Instrument

Product core positioning and application scenarios

1. Product positioning

Prosonic T FMU30 is a compact ultrasonic level measurement transmitter that uses non-contact measurement method and is suitable for continuous level monitoring of liquids, paste materials, and coarse granular materials. It supports 4-20mA signal output for system integration.

2. Scope of application

Measurement objects: liquids (such as clean water, sewage, and oil), paste like materials (such as mud and paint), and coarse granular materials (such as gravel and coal).

Measurement range (varies depending on sensor size):

1.5-inch sensor: maximum 5m (16ft) in liquid, maximum 2m (6.6ft) in bulk material, blind spot 0.25m (0.8ft).

2-inch sensor: maximum 8m (26ft) in liquid, maximum 3.5m (11ft) in bulk material, blind spot 0.35m (1.1ft).

Measurement Principles and Core Technologies

1. Measurement principle (time-of-flight method)

The sensor emits ultrasonic pulses onto the surface of the material, which are reflected and received by the sensor.

The device measures the time difference t between pulse emission and reception, combined with the sound velocity c, and calculates the distance D from the sensor diaphragm to the material surface using the formula D=c ⋅ t/2.

Based on the user's preset empty tank distance E, calculate the actual liquid level L using the formula L=E-D.

Built in NTC temperature sensor can automatically compensate for the impact of temperature changes on sound velocity, ensuring measurement accuracy.

2. Key functions

Interference echo suppression: Filter the interference echoes generated by container edges, welds, internal equipment, etc., to avoid misjudging the liquid level.

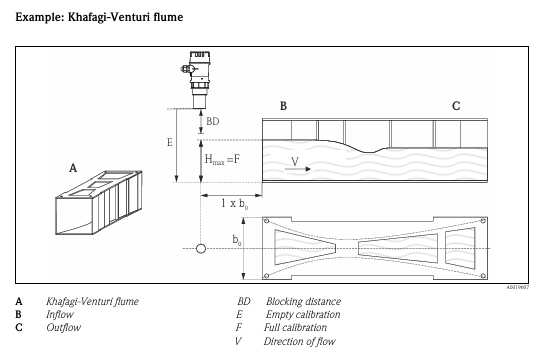

Linearization function: Supports up to 32 linearization points, can convert measurement values into length, volume, or flow units (applicable for open channel/weir flow calculation), and pre stores a linearization table for horizontal cylindrical tank volume calculation.

Signal output: 4-20mA analog signal, customizable output during alarm (compliant with NAMUR NE43 standard), output damping can be freely set within 0-255s.

Technical parameters and performance indicators

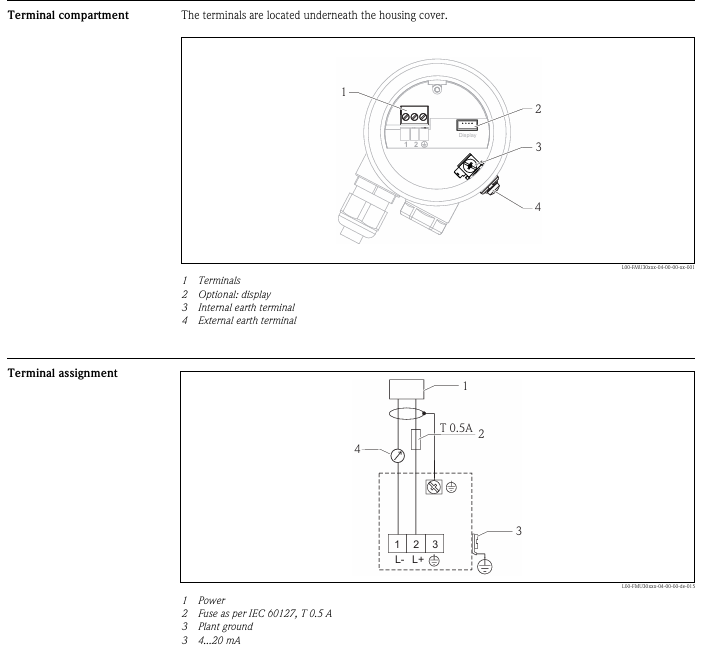

1. Basic electrical parameters

Parameter specifications

Supply voltage 14-35V DC

Power consumption 51mW-800mW

Current consumption 3.6-22mA

The cable interface has a cross-sectional area of 0.25-2.5mm ² (24-14 AWG), and the cable entry is G/2 "or 1/2" NPT. The recommended cable diameter is 6-10mm

The protective circuit is equipped with reverse polarity protection, radio frequency interference (RFI) protection, and overvoltage spike protection

2. Measurement performance

Resolution: 1mm (0.04in).

Maximum measurement error: ± 0.2% of the sensor's maximum range (in accordance with EN 61298-2 standard, under reference operating conditions).

Typical measurement error: better than ± 3mm (± 0.12in) or 0.2% of the measured distance (whichever is greater).

Response time: Minimum of 2 seconds (depending on parameter settings).

Pulse frequency: Maximum 0.5Hz (varies depending on device type and parameters).

3. Environmental and process adaptability

Category specifications

Operating temperature range: -20 ° C to+60 ° C (-4 ° F to+140 ° F, it is recommended to install a rain cover when using outdoors); Storage: -40 ° C to+80 ° C (-40 ° F to+176 ° F)

Protection level: IP66/IP68 when the shell is closed (24 hours at 1.83m underwater); IP20 when the shell is opened

Vibration resistance meets DIN EN 60068-2-64 standard, 20-2000Hz, 1 (m/s ²)/Hz, 3 × 100min

Electromagnetic compatibility (EMC) complies with EN 61326 standard, industrial environment anti-interference level, EMC impact<1% of full scale

Process temperature -20 ° C to+60 ° C (-4 ° F to+140 ° F)

Process pressure 0.7-3bar abs. (10.15-43.5psi abs.)

Mechanical structure and installation requirements

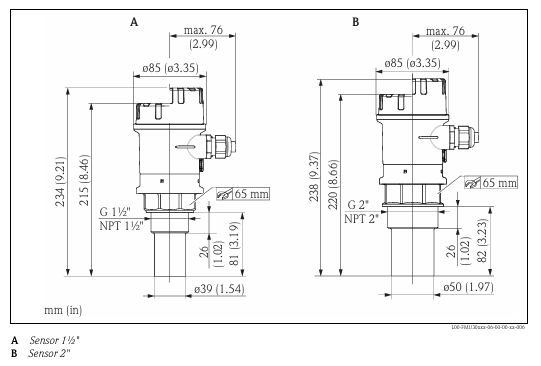

1. Mechanical specifications

Size and weight:

1.5-inch sensor: weighs approximately 0.75kg (1.65lbs), with process connections of G 1.5 "or NPT 1.5".

2-inch sensor: weighs approximately 0.8kg (1.76lbs), with process connections of G 2 "or NPT 2".

Material: The outer shell is PBT-FR (flame retardant polybutylene terephthalate), the sensor material contact part is PP (polypropylene), and the seal is EPDM (ethylene propylene diene monomer rubber), ensuring chemical compatibility and durability.

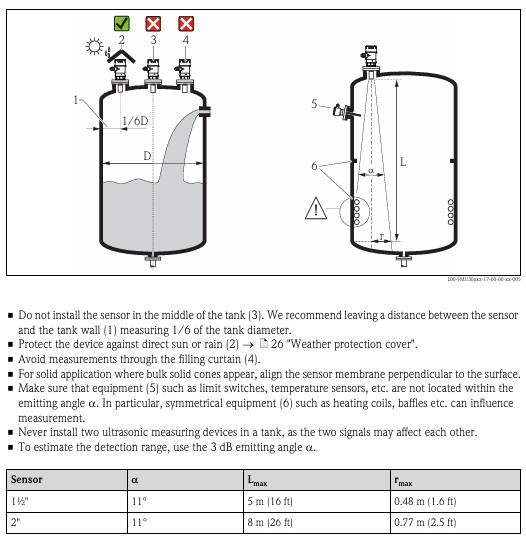

Installation specifications

(1) General requirements

Avoid installing in the center of the tank. It is recommended that the distance between the sensor and the tank wall be 1/6 of the tank diameter to prevent reflection interference from the tank wall.

To avoid the measurement path passing through the feeding curtain, the sensor membrane should be perpendicular to the material surface in the application of bulk materials (to avoid the influence of conical accumulation).

Equipment inside the tank (such as limit switches and temperature sensors) should avoid ultrasonic emission angles (11 °), and two ultrasonic measuring devices cannot be installed in the same tank to prevent signal interference.

(2) Special scenario installation

Narrow axis installation: PE or PVC waveguide pipes with a diameter of ≥ 100mm should be used, and regular cleaning should be carried out to avoid contamination affecting the measurement.

Flow measurement (open channel/weir): Installed on the inflow side, near the maximum water level H max (with a blind zone reserved), the sensor diaphragm is parallel to the water surface and centrally installed above the channel/weir.

Nozzle installation: If the blind spot requirements cannot be met, a smooth and edgeless nozzle should be used, with a nozzle diameter that matches the maximum length (such as a DN50 nozzle with a maximum length of 80mm and a DN100 nozzle with a maximum length of 300mm).

Operation mode and functional configuration

1. Local operation

Display and buttons: 4-line pure text LCD display screen (supporting 7 languages: German, English, Spanish, French, Italian, Japanese, Dutch), equipped with navigation and confirmation keys, allowing for intuitive viewing of measured values, envelope curves (for fault diagnosis), and alarm information.

Hardware lock: After long pressing the lock button, you need to enter the unlock parameter (100) to operate again to prevent accidental touch.

2. Remote operation

Connect to a PC via Commubox FXA291 (communication box) and ToF Adapter FXA291 (time-of-flight adapter), and use FieldCare software (Endress+Hauser's FDT asset management tool) to achieve remote configuration. The supported functions include envelope curve signal analysis and linearization table editing (import/export).

Equipment data upload/download, measurement point document recording.

Compatible with Ethernet, HART, PROFIBUS PA and other protocols, supporting third-party FDT standard devices.

Certification qualifications and compliance

Certification type specific standards/certification content

CE certification meets the requirements of EU directives, passes relevant tests, and bears the CE mark

Explosion-proof certification ATEX II 1/2G Ex ia IIC T5 Ga/Gb、IECEx Ex ia IIC T5 Ga/Gb、CSA C/US Class I Div.1 Gr.A-D、NEPSI Zone 0/1 Ex ia IIC T5 Ga/Gb

Environmental and safety standards comply with DIN EN 60529 (protection level), EN 61326 (EMC), NAMUR NE43 (alarm signal), EN 61298-2 (measurement accuracy), etc

Ordering Information and Accessories

1. Ordering Code Rules

It is necessary to specify a combination of 7 dimensions of parameters to generate a complete order number, with key parameters including:

010 (certification type): such as AA (non hazardous area), BB (ATEX explosion-proof), IB (CSA explosion-proof).

020 (display and operation): such as G (no local display), H (with envelope curve display+button).

040 (sensor specifications): such as AA (1.5-inch sensor), AB (2-inch sensor).

050 (process connection): such as GGF (G 1.5 "thread, PP material), RHF (NPT 2" thread, PP material).

2. Standard accessories and optional accessories

Standard supply scope: transmitter body, brief instruction manual (KA01054F), CD-ROM document, explosion-proof version including safety instructions, PC material for nuts (GGF/GHF version), EPDM sealing ring.

Optional accessories: Installation bracket (316Ti or galvanized steel material), threaded flange (PP/PVDF/316L material, suitable for different DN specifications), cantilever bracket+installation frame/wall frame, rain cover (PBT material, suitable for -50 ° C to+150 ° C), Commubox FXA291 and ToF Adapter FXA291.

Maintenance and Safety Tips

Daily maintenance: Regularly clean the sensor membrane to avoid contamination affecting ultrasonic transmission; During narrow axis installation, it is necessary to regularly clean the waveguide.

Safety precautions: Explosion proof versions must strictly follow the corresponding safety instructions (such as XA01054F, XA01080F), and installation and maintenance must be carried out by professional personnel; Avoid contact between the sensor and high vapor pressure media (such as ethanol and acetone), and consult the manufacturer for compatibility if necessary.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923