K-WANG

Woodward GS10 Gas Metering System

Woodward GS10 Gas Metering System

Application scenarios

The Woodward GS series gas metering system is designed specifically for industrial gas turbines with output power ranging from 200kW to 30MW. It provides a reliable and cost-effective interface between electronic engine control systems and gas turbines in applications such as power generation, compressors, and mechanical drives. The GS10 valve is compatible with various gas fuels, such as natural gas, acidic gases, liquefied petroleum gas, methane, propane, butane, and hydrogen.

Product description

Structure and Design: GS10 adopts a rotary plate valve, integrates electric actuators and non-contact position sensors to achieve precise flow control. The use of rare earth permanent magnets in its efficient electromagnetic circuit reduces the packaging size. The integrated brushless DC actuator and valve design eliminates the backlash problem of gear motors and avoids the resolution and periodic oscillation issues of stepper motors.

Core Features

Self cleaning rotary plate valve with anti pollution properties.

Fully electric drive.

Only a single moving component.

Resistant to vibration and has a wide operating temperature range.

Quick response and high precision in flow control.

No on-site adjustment or assembly is required.

Standard 4-20mA interface with discrete fault output and shutdown function.

Some models have been certified for hazardous locations in North America.

Flow control and calibration: Gas flow control is usually achieved by accurately setting the port area of the metering valve based on assumed values of gas characteristics, pressure, and temperature. The GS10 valve is calibrated in the factory under actual flow conditions to provide accurate valve measurement area based on input signal requirements. The actual fuel flow rate depends on the valve area, gas pressure, gas temperature, and the gas itself. The fuel flow equation for the GS10 valve is located in the GS manual and available software programs, and can be used to set the GS10 valve under any specific site conditions.

Valve size: The GS10 valve is suitable for gas turbines with output power ranging from 2-15MW (depending on the characteristics and conditions of the available fuel gas). The rotary plate valve and actuator are located within a single low-carbon steel casing, with a 2-inch raised face flange gas connection and standard flange spacing. The measuring port size of GS10 valve is available in two types: 0.5 square inches (323 square millimeters) and 1.0 square inches (645 square millimeters).

Technical Parameter

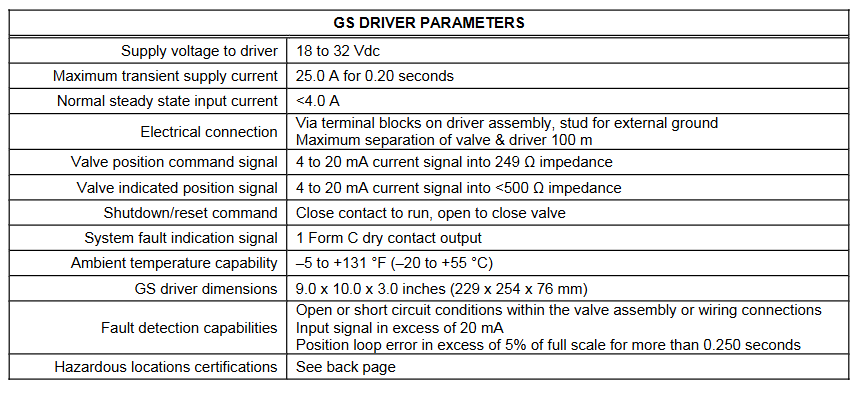

GS driver parameters

Power supply voltage: 18-32Vdc.

Maximum transient power supply current: 25.0A, lasting for 0.20 seconds.

Normal steady-state input current:<4.0A.

Electrical connection: through the wiring terminals on the driver components and external grounding poles; The maximum distance between the valve and the actuator is 100m.

Valve position command signal: 4-20mA current signal, input impedance 249 Ω.

Valve indication position signal: 4-20mA current signal, input impedance<500 Ω.

Shutdown/reset command: Close the contact to operate, open to close the valve.

System fault indication signal: 1 set of C-type dry contact output.

Environmental temperature capability: -5 to+131 ° F (-20 to+55 ° C).

GS drive size: 9.0 x 10.0 x 3.0 inches (229 x 254 x 76mm).

Fault detection capability: open or short circuits in valve components or wiring connections; The input signal exceeds 20mA; the position loop error exceeds 5% of the full range and lasts for more than 0.250 seconds.

Dangerous place certification: see next page.

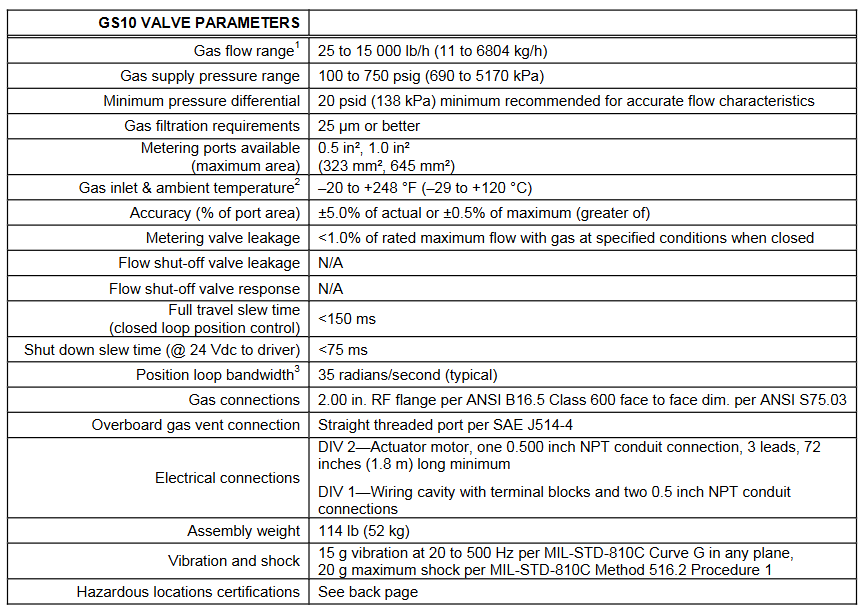

GS10 valve parameters

Gas flow range: 25-15000lb/h (11-6804kg/h).

Gas supply pressure range: 100-750PSI (690-5170kPa).

Minimum pressure difference: To ensure accurate flow characteristics, it is recommended to have a minimum of 20 psid (138 kPa).

Gas filtration requirements: 25 μ m or higher precision.

Available metering ports (maximum area): 0.5 square inches, 1.0 square inches (323 square millimeters, 645 square millimeters).

Gas inlet and ambient temperature: -20 to+248 ° F (-29 to+120 ° C) (note: dry gas is required when the temperature is below 0 ° C (32 ° F)).

Accuracy (percentage of port area): ± 5.0% of actual value or ± 0.5% of maximum value (whichever is greater).

Leakage of metering valve: Under specified conditions, the leakage amount when the gas is closed is less than 1.0% of the rated maximum flow rate.

Leakage of flow stop valve: Not applicable.

Flow stop valve response: Not applicable.

Full travel conversion time (closed-loop position control):<150ms.

Shutdown conversion time (when the driver voltage is 24Vdc):<75ms.

Position loop bandwidth: 35 radians per second (typical value) (note: the system dynamics are roughly second-order. The bandwidth is determined by the amplitude response at -6dB, and the GS driver voltage is 24Vdc).

Gas connection: 2.00 inch RF flange, compliant with ANSI B16.5 Class 600; Face to face dimensions comply with ANSI S75.03.

External gas emission connection: straight threaded port in accordance with SAE J514-4.

Electrical connection: Zone 2- actuator motor, one 0.500 inch NPT conduit connection, 3 wires, minimum 72 inches (1.8m) long; Zone 1- Wiring chamber with terminal blocks and two 0.5-inch NPT conduit connections.

Component weight: 114lb (52kg).

Vibration and impact: 15g vibration at 20-500Hz on any plane, in accordance with MIL-STD-810C curve G; maximum impact of 20g, in accordance with MIL-STD-810C method 516.2 procedure 1.

Dangerous place certification: see next page.

Regulatory compliance

European compliance (CE marking): only applicable to units with CE marking.

EMC Directive (GS Drive): Complies with Council Directive 89/336/EEC of May 3, 1989 on the harmonization of the laws of Member States relating to electromagnetic compatibility.

ATEX - Directive on Potential Explosive Atmospheres (GS Drivers): Complies with Council Directive 94/9/EEC of March 23, 1994 on the harmonization of the laws of Member States relating to equipment and protective systems used in potentially explosive atmospheres. LCIE 01. ATEX.6012 X Zone 2, Class 3, Class II Group G, EEx nC/L IIC T4。 Special conditions for safe use: The GS driver must be installed in an IP54 rated enclosure that meets the requirements of European standard EN 50021 (1999) and must be connected to the GS10 valve/actuator.

North American Compliance: Only applicable to units with UL or CSA agency markings.

GS10 valve CSA: CSA certified, suitable for Class I, Zone 1, Groups C and D, T3C at ambient temperature of 120 ° C. Can be used in Canada and the United States.

GS driver UL: UL certified, suitable for Class I, Zone 2, Groups A, B, C, and D, with an ambient temperature of 55 ° C. Can be used in Canada and the United States. Certified by CSA, suitable for Class I Zone 1, Groups A, B, C, and D, T4A at an ambient temperature of 55 ° C. Can be used in Canada and the United States.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector