K-WANG

HIMA HIMatrix F2 DO 8 01 Remote I/O Module

ESD protection: Only personnel with knowledge of electrostatic protection are allowed to operate. ESD wristbands should be worn during work, and when idle, they should be stored in anti-static packaging to avoid static electricity damaging the internal circuits of the module.

HIMA HIMatrix F2 DO 8 01 Remote I/O Module

Safety regulations and environmental requirements

(1) Core security requirements

Expected use and protective measures

The module is a SELV/PELV safety ultra-low voltage device, which poses no direct danger to itself. For use in Ex areas (such as Zone 2), additional explosion-proof requirements must be met (such as installation in enclosures with protection levels above IP54);

ESD protection: Only personnel with knowledge of electrostatic protection are allowed to operate. ESD wristbands should be worn during work, and when idle, they should be stored in anti-static packaging to avoid static electricity damaging the internal circuits of the module.

Residual risk and emergency response

Residual risk sources: engineering design defects (such as wiring errors), user program vulnerabilities (such as failure to configure fault safety logic), hardware failures (such as relay adhesion), which need to be avoided through compliant configuration and regular testing;

Emergency principle: The module is an integral part of the safety system, and in the event of a malfunction, all outputs must be switched to the "power-off safety state" (such as relay disconnection). It is prohibited to perform operations that obstruct the safe operation of the system in emergency scenarios (such as forcibly activating outputs).

(2) Environment and installation conditions

Specific parameter specifications for the required type

The protection level IP20 (IEC 60529) needs to be installed inside the control cabinet to prevent dust and condensation. Ex Zone 2 requires additional enclosure protection

If the working temperature exceeds 0...+60 ° C, it needs to be downgraded to avoid oxidation of relay contacts and overheating of the circuit

Storage temperature -40...+85 ° C must be met during transportation or idle to avoid component damage

Pollution level II (IEC/EN 61131-2) is applicable to non-conductive dust environments to avoid short circuit risks

Evaluation of heat dissipation and insulation performance is required in high-altitude areas with an altitude of less than 2000 meters

Supply voltage 24 VDC (-15%...+20%) ripple factor ≤ 15%, requires independent power supply (recommended PELV/SELV power supply), equipped with 10A delay fuse

Product Description and Core Features

(1) Basic characteristics of module

Functional positioning and compatibility

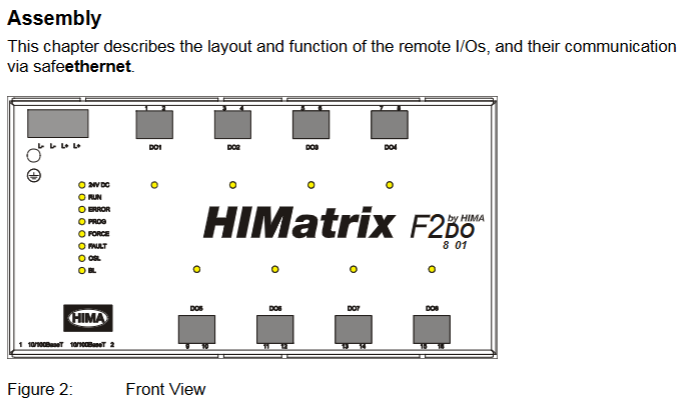

Role: As a remote I/O, unable to run user programs independently, requiring SafeEthernet to receive controller instructions and expand the digital output interface of the HIMax/HIMatrix system;

Safety certification: certified by T Ü V, supporting SIL 3(IEC 61508/61511/62061)、Cat. 4(EN 954-1)、PL e(EN ISO 13849-1), Simultaneously comply with explosion-proof and industrial standards such as ATEX Zone 2 and UL 508;

Model difference: Divided into "F2 DO 8 01 (adapted to ELOP II Factory, part number 98 2200407)" and "F2 DO 8 01 SILworX (adapted to SILworX, part number 98 2200481)", the hardware is the same, only the software adaptation is different.

Core Components and Security Design

Relay output circuit: Each output is equipped with 2 forced guide contact safety relays and 1 standard relay, with a built-in 3.15A fuse (limiting switch current to 60% of rated value, in compliance with VDE 0116), and the contacts support 250 VAC/250 VDC voltage, which can be used for safe shutdown control;

Fault response mechanism: When an output fault is detected (such as relay adhesion or abnormal voltage), only the corresponding output is cut off for a single fault, and all outputs are cut off for an overall module fault. At the same time, the ERROR LED is activated and a fault code is reported;

Self testing function: supports MOT (maintenance testing) and FTT (fault tolerance time) testing, can detect safety switches, relay voltage, temperature thresholds, etc., to ensure output reliability.

(2) Hardware Structure and Interface

Core parameters

|Category | Parameter Value | Description|

|------|--------|------|

|Output channel | 8 channels | Each independent relay, normally open contact (NO), potential isolation|

|Output capacity | 250 VAC/250 VDC, maximum 3 A | Switching life under Ohmic load ≥ 3 × 10 ⁶ times|

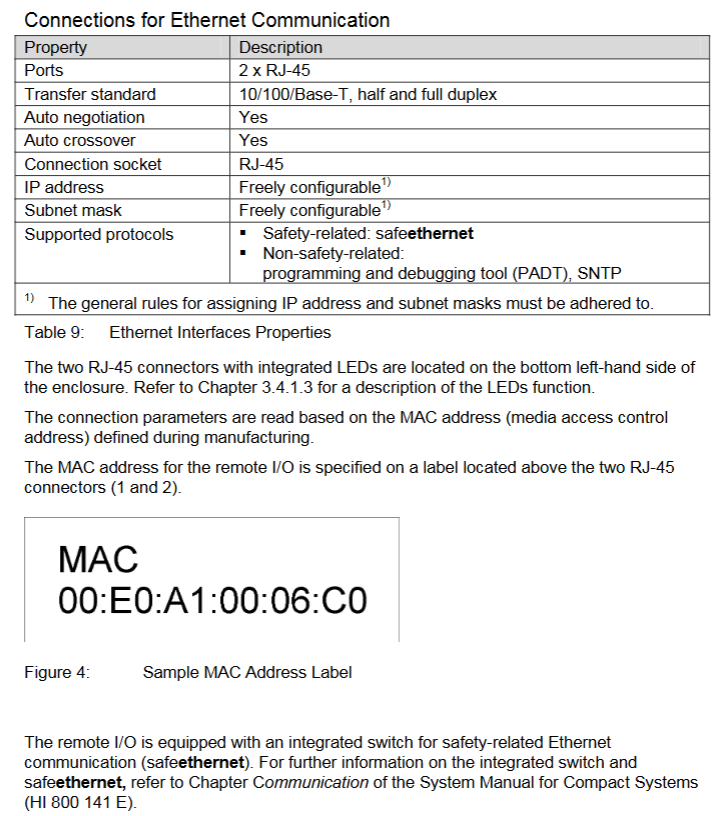

|Communication Interface | 2 × RJ-45 (SafeEthernet) | Supports 10/100 Base-T, auto negotiation rate/duplex, auto crossover (no need for crossover)|

|Supply current | Maximum 0.6 A | 24 VDC supply, power dissipation 18-46 W (depending on load)|

|Dimensions (H × W × D) | 114 × 207 × 86 mm (including fasteners) | Weight approximately 1.3 kg, supporting 35 mm DIN rail installation|

Grouping and meaning of LED indicator lights

There are 4 sets of LEDs in the front-end of the module, which perform a full light test when powered on. The status meanings of each indicator light are as follows:

Working voltage light (24 VDC, green): normally on indicates normal power supply, off indicates no voltage;

System lights (red/yellow, multiple lights):

Red light (ERROR): Constant light indicates that the module has entered the ERROR STOP state (such as hardware failure), slow flashing indicates loading the operating system;

Yellow light (Initiat/STOP/RUN): Constant light indicates corresponding status, slow flashing indicates loading configuration or forced function activation;

Communication light (green/yellow next to RJ-45): Green light constantly on indicates full duplex, flashing indicates conflict; A constant yellow light indicates a normal physical connection, while a flashing light indicates data transmission;

I/O light (DO 1-8, yellow): normally on indicates that the output is powered on (relay is engaged), and off indicates that the output is powered off (safe state).

Reset button function

Reserved reset hole in the upper left corner of the module (triggered by an insulating pin), only used for scenarios where the administrator account is forgotten or the IP address does not match: When restarting, press and hold the reset button for ≥ 20 seconds to restore the default parameters (IP: 192.168.0.99; SRS: 60000.200.0 (SILworX)/60000.0.0 (ELOP II Factory)), and clear the user account (only the default administrator account is retained, password is empty).

Installation and configuration process

(1) Module installation and wiring

Installation prerequisites

It needs to be fixed on a 35 mm DIN rail with reserved heat dissipation space around it (high power dissipation, avoid being adjacent to heating equipment);

Ex Zone 2 installation requires additional requirements: enclosure protection level ≥ IP54 (compliant with EN 60529), enclosure must be labeled with a "power off operation only" warning, equipped with a 10A delay fuse, PELV/SELV power supply, and reference to EN 60079-15 standard (terminal wiring, creepage distance, etc.).

Wiring specifications

Power wiring: Connect the positive terminal of the 24 VDC module to the "+" terminal and the negative terminal to the "-" terminal. It needs to be powered independently to avoid being in line with the power circuit;

Relay output wiring: Each output corresponds to 2 terminals (such as DO1 corresponding to terminal 1/2, A/B contacts), which are normally open contacts. The load needs to be equipped with external fuses according to the voltage type (DC loads require additional anti reverse protection);

Communication wiring: The RJ-45 interface is connected to a SafeEthernet network, supporting daisy chain topology, and requires the use of CAT 5e or higher shielded cables (shielded layer single ended grounding to reduce interference).

(2) Software configuration configuration

SILworX configuration (version ≥ 7)

Core Parameters (Module tab):

Basic parameters: Configure module name, IP address, subnet mask (default 192.168.0.99), SRS (system rack slot address, default 60000.200.0);

Fault monitoring: Enable MOT/FTT testing, configure temperature threshold (output cut-off in case of overheating), read fault codes (e.g. 0x0001 indicates module fault, 0x0400 indicates first level overheating).

Channel configuration (DO 8: Channels tab): Assign global variables to each output (DO1-DO8), set output values (1=power on, 0=power off), and monitor single channel faults (such as 0x10 indicating relay 1 feedback error).

ELOP II Factory configuration (version<7)

Assign system signals to output channels through the "Signal Editor", with configuration parameters similar to SILworX. The core difference lies in the signal mapping method (based on "signal name channel" association rather than variable allocation), and the fault code is consistent with the state definition (such as Mod. Error Code 0x0010 indicating configuration error).

Operation, maintenance, and troubleshooting

(1) Daily operation and diagnosis

operation monitoring

Real time status can be viewed through LED: the RUN light is always on to indicate normal operation, the ERROR light is on to indicate a fault, and the I/O light corresponds to the output status;

Detailed diagnosis: Read fault logs (such as relay adhesion, communication interruption) through programming tools, support online viewing of output feedback values (ensure that instructions are consistent with actual status).

Common faults and solutions

|Fault phenomenon | Possible causes | Troubleshooting steps|

|All outputs are unresponsive (all I/O lights are off) | 1 The module has not entered the RUN state; 2. Power supply failure; 3. Communication interruption | 1 Check the system light (whether it is in RUN state); 2. Measure 24 VDC power supply; 3. Check the Ethernet light (whether there is a physical connection)|

|Single output fault (ERROR light on, fault code 0x10) | 1. Relay 1 feedback error; 2. Contact adhesion | 1 Power off and restart module; 2. Check the load circuit (whether there is a short circuit); 3. Module replacement verification|

|Communication interruption (communication light off) | 1 IP address conflict; 2. Cable malfunction; 3. Controller offline | 1 Check if the module IP and PADT are on the same network segment; 2. Replace the communication cable; 3. Confirm whether the controller is operating normally|

(2) Maintenance and Lifecycle Management

regular maintenance

Operating system update: Utilize system downtime to load the latest version of the operating system through programming tools (modules must be in STOP state), and backup configuration before updating to avoid data loss;

Proof Test: Conducted every 10 years, the test includes relay output on/off, fault response (such as simulating overheating), and communication link integrity. Refer to the HIMA Safety Manual (HI 800 023 E).

Scrap and transportation

Scrap: Industrial users need to dispose of modules containing electronic components in accordance with environmental protection requirements. They can contact HIMA to sign a scrap agreement, which prohibits the arbitrary disposal of modules containing electronic components;

Transportation/Storage: Original anti-static packaging should be used to avoid mechanical impact, and the storage temperature should be maintained at -40...+85 ° C to avoid humid environments.

Key terms and compliance

Core Terminology

SafeEthernet: The HIMA secure communication protocol ensures the safety of data transmission between the controller and remote I/O (compliant with SIL 3 requirements);

SRS (System. Rack. Plot): Module addressing method used to locate the position of remote I/O in the system (default 60000.200.0);

MOT (Maintenance Test): Maintenance testing to check the hardware status of safety relays, feedback loops, etc;

FTT (Fault Tolerance Time): The maximum time a module can maintain a safe state after detecting a fault.

Compliance certification

The module complies with multiple international standards, and core certifications include:

Safety standards: IEC 61508 (SIL 3), IEC 61511 (SIL 3), EN ISO 13849-1 (PL e);

Explosion proof standards: ATEX Zone 2 (EN 60079-15), UL Class I DIV 2;

Industrial standards: UL 508, NFPA 79, EN 54-2 (fire alarm).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923