K-WANG

HIMA HIMatrix F35 Manual Safety-Related Controller

HIMA HIMatrix F35 Manual Safety-Related Controller

Product Overview

1. Core positioning and certification

HIMatrix F35 is a high safety compact programmable electronic controller launched by HIMA, designed specifically for industrial automation safety control scenarios. It can replace traditional decentralized relay circuits and is suitable for safety related functions such as emergency shutdown, process protection, and equipment interlocking. This controller has been certified by T Ü V and supports up to SIL 3 safety level (compliant with IEC 61508, IEC 61511, IEC 62061 standards). It also meets safety specifications such as EN 954-1 Cat.4 and EN ISO 13849-1 PL e, and is suitable for Zone 2 hazardous environments (compliant with EC Directive 94/9/EG ATEX directive). Some models can be used in underwater scenarios (compliant with ISO 13628-6 standard).

2. Model variants and environmental adaptation

The controller offers 6 variants, each adapted to different programming tools and usage environments, with the following core differences:

Model Programming Tool Operating Temperature Special Design Applicable Scenarios

F35 01 ELOP II Factory 0~60 ℃ Standard Metal Shell Conventional Industrial Environment

F35 011 (-20 ℃) ELOP II Factory -20~60 ℃ Electronic components coated with protective paint Low temperature industrial environment

F35 012 (Subsea/-20 ℃) ELOP II Factory -20~60 ℃ V2A stainless steel shell, impact and vibration resistant subsea production control system

F35 01 SILworX SILworX 0~60 ℃ Standard Metal Shell Conventional Industrial Environment (OS ≥ 7 version)

F35 011 SILworX (-20 ℃) SILworX -20~60 ℃ Electronic components coated with protective paint Low temperature industrial environment (OS ≥ 7 version)

F35 012 SILworX (Subsea/-20 ℃) SILworX -20~60 ℃ V2A stainless steel shell, impact and vibration resistant subsea production control system (OS ≥ 7 version)

3. Physical and Electrical Basic Parameters

Protection level: IP20 (standard), Zone 2 environment needs to be equipped with a protective shell of IP54 or above;

Power supply requirements: 24VDC (-15%~+20%), in compliance with SELV/PELV safety standards, external 10A delay fuse needs to be connected in series;

Power consumption: 15-29W (varying with output load);

Physical dimensions: width 257mm x height 114mm x depth 97mm (excluding plug);

Weight: The standard model weighs about 1.2kg, while the subsea model weighs about 1.7kg;

Storage temperature: -40~+85 ℃, altitude<2000m, pollution level II (compliant with IEC/EN 61131-2).

Hardware configuration and functional details

1. Core configuration of input/output/counter

(1) Digital input (24 channels)

Electrical characteristics: Non isolated, current absorption logic, 24V type 1 (compliant with IEC 61131-2);

Voltage range: 0~30V, default low level<7V, high level>13V, threshold can be customized through system parameters;

Current parameters: approximately 3.5mA at 24V, approximately 4.5mA at 30V, input resistance<7k Ω;

Overload protection: -10V~+35V overvoltage protection;

Wiring and power supply: divided into 3 groups (8 channels per group), each group is powered by independent LS+(24V), supporting passive mechanical contacts and active signal source connections, with a maximum wiring distance of 300m;

Safety feature: Following the principle of "power-off tripping", a low-level safety state is output in case of a fault, and channel faults are fed back through ERROR CODE.

(2) Digital output (8 channels)

Load capacity: Channels 1-3/5-7( 0.5A@60 ℃), channel 4/8( 1A@60 ℃ 2A@50 ℃), minimum load 2mA/channel;

Electrical characteristics: Non isolated, common ground (L -) design, output voltage of L+minus 2V, maximum internal voltage drop of 2W (at 2A), leakage current ≤ 1mA (at low level);

Overload protection: Automatic power-off in case of single channel overload, and automatic restoration after fault relief; When the total current exceeds 7A, all outputs will be powered off and the cycle will retry;

Wiring requirements: The 1-pole switch output should be paired with the corresponding channel group's L-ground (2-pole connection), and it is recommended to parallel protect diodes for inductive loads;

Safety feature: When a module or channel fails, the output switches to a power-off safety state and activates the FAULT LED indicator light.

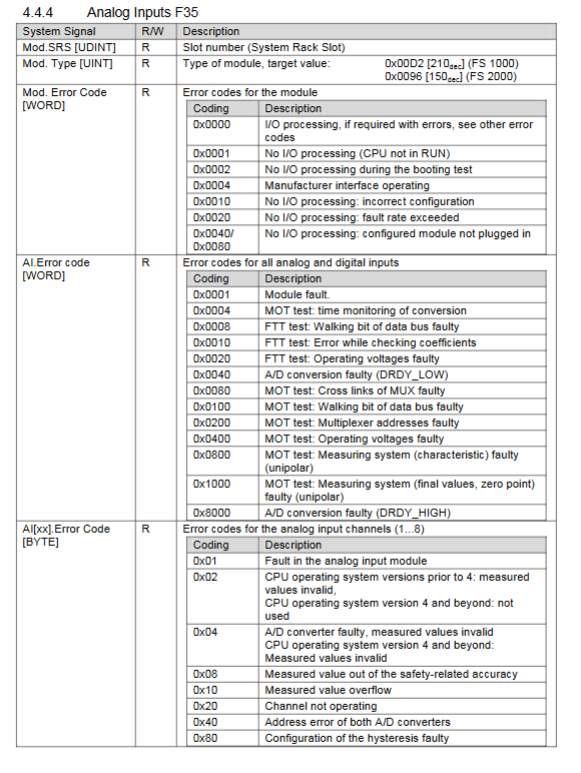

(3) Analog input (8 channels)

Measurement range: Unipolar 0~10V voltage (12 bit resolution), 0~20mA current (requires external Z7301/Z7302 shunt adapter);

Accuracy indicators: Measurement accuracy at 25 ℃ ± 0.1% full range, full temperature range ± 0.5% full range, safety related accuracy ± 2% full range;

Electrical characteristics: Input resistance of 1M Ω, internal resistance of signal source ≤ 500 Ω, sampling time of about 45 μ s, measurement value refreshed once per controller cycle;

Power supply and wiring: Each channel is equipped with a 24~28V, ≤ 46mA short-circuit protection transmitter power supply, which requires the use of shielded twisted pair cables (up to 300m in length), with the shielding layer grounded at one end (controller side). Unused channels need to be short circuited;

Extended function: Short circuit/open circuit monitoring of digital output can be achieved through external resistors and voltage regulators (compliant with SIL 3 requirements).

(4) Counter (2 independent channels)

Electrical characteristics: Non isolated, supports 5V/24V input voltage (configured through system parameters), input current 1.4mA (5V)/6.5mA (24V), input impedance 3.7k Ω;

Performance parameters: 24 bit resolution, maximum count value 16777215, minimum pulse width 5 μ s, maximum input frequency 100kHz (5V/24V), trigger edge as falling edge, pulse duty cycle 1:1;

Working mode: Supports 3 modes - ① Direction controllable counting (input B controls increase or decrease); ② Fixed direction counting (user program controls increase or decrease); ③ Gray code decoding (compatible with 3-bit absolute rotary encoder);

Wiring requirements: Each channel contains 3 inputs: A (counting input), B (direction/bit 1), and Z (reset/bit 2), with a maximum wiring distance of 500m, and both ends of the shielded twisted pair are grounded.

2. Communication interface configuration

(1) Ethernet interface (4 RJ-45 ports)

Transmission characteristics: Supports 10/100Base-T, half duplex/full duplex automatic negotiation, Auto Crossover automatic adaptation to cable types;

Protocol support: Safety related protocols (safeEthernet), non safety protocols (Modbus TCP, OPC, SNTP, TCP-SR), EtherNet/IP only supports ELOP II Factory;

Port allocation: UDP ports (8000 for programming tools, 8001/ELOP II Factory remote I/O configuration, 8004/SILworX remote I/O configuration, 502/Modbus), TCP ports (502/Modbus, 44818/EtherNet/IP);

Hardware features: Integrated switch, MAC address fixed (pasted above the port), IP address and subnet mask can be freely configured (default IP: 192.168.0.99).

(2) Fieldbus interface (3 9-pin D-sub connectors)

Interface support module compatible protocol core usage

FB1 PROFIBUS master/slave, RS485/RS232/RS422, INTERBUS master PROFIBUS DP, Modbus, ComUserTask master fieldbus communication

FB2 communicates with FB1 via redundant or backup fieldbus

FB3 fixed RS485 Modbus (master/slave), ComUserTask auxiliary fieldbus communication

3. Other hardware functions

LED indicator lights: including power light (24VDC green), system light (RUN/RROR/ROG/FORCE/AULT, etc.), communication light (Ethernet/fieldbus status), I/O light (independent indication for each channel), all LEDs light up synchronously during boot;

Reset button: located in the upper left corner of the casing, it needs to be long pressed with an insulating pin for 20 seconds and restarted to activate the controller. After resetting, the IP address (default 60000.0.0) and system ID will be restored to default, only valid for administrator accounts;

Hardware clock: Built in gold capacitor, can maintain the clock for about one week after power failure;

ESD protection: It is necessary to wear an anti-static wristband for operation, and store it in its original packaging when idle.

Software Programming and Configuration

1. Adaptation of programming tools

SILworX: Suitable for processor OS version ≥ 7, communication OS ≥ 12, supports hardware parameter configuration, variable mapping, fault code reading, project files are not compatible with ELOP II Factory;

ELOP II Factory: Suitable for processor OS version<7, communication OS<12, supports signal editing, channel assignment, protocol configuration, can be used to upgrade OS to version 7 and above, and later switch to SILworX.

2. Core configuration functions

(1) Variable and parameter configuration

Digital input: configurable channel enabled (Used), Hysteresis LOW/HIGH threshold, read analog values (0~3000 corresponds to 0~30V) and fault codes;

Digital output: Configure output values (BOOL type, 1=energized/0=de energized), read channel and module fault codes;

Analog input: Select resolution (FS1000:0~1000/0~10V; FS2000:0~2000/0~10V), configure channel enable, read measurement values and fault codes;

Counter: Configure input voltage (5V/24V), working mode, counting direction, reset mode, read count value, timestamp, overflow status, and fault code.

(2) Fault code system

The controller outputs fault codes through system variables, supporting channel level and module level fault localization. The core fault codes have the following meanings:

Digital input faults: 0x01 (module fault), 0x04 (A/D converter fault), 0x08 (measurement value exceeding safety accuracy), etc;

Digital output faults: 0x02 (overload power-off), 0x04 (output value read back error), 0x200 (total current exceeding limit), etc;

Analog input faults: 0x04 (A/D conversion fault), 0x08 (measurement value exceeds safety accuracy), 0x20 (channel not enabled), etc;

Counter malfunction: 0x02 (incorrect comparison of count values), 0x04 (incorrect comparison of timestamps), 0x08 (incorrect parameter settings), etc.

(3) Wiring variant configuration

Analog input connected to mechanical contacts: Z7308 shunt adapter (overvoltage protection) is required, with a supply voltage of 26.7~27.3V, switching threshold: L → H=6V (1200 digits), H → L=3V (600 digits), fault threshold ≤ 0.5V or ≥ 8.4V;

Digital input connected to mechanical contacts: 3 independent supplies (16.7~26.9V), each requiring 1 digital input to monitor the supply voltage. Switching threshold: L → H>12V, H → L<10V, fault threshold<2V or=supply 1.1V.

Installation and Startup

1. Installation requirements

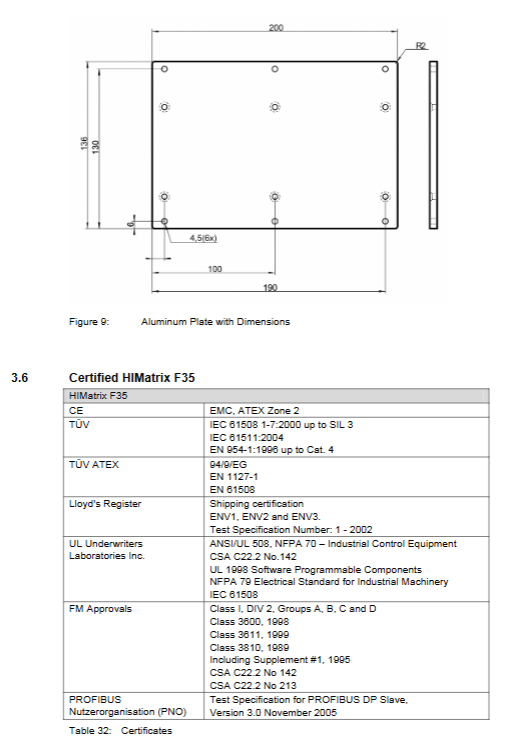

Installation method: Standard 35mm DIN rail installation, submarine type (F35 012 series) mounting plate fixation;

Additional requirements for Zone 2 environment: ① Installed in a protective enclosure above IP54, with the enclosure labeled "Operable only in power-off state"; ② The shell needs to meet the heat dissipation requirements (15-29W); ③ The power supply is 24VDC PELV/SELV type; ④ The wiring complies with DIN EN 60079-15/14 standard;

Wiring specifications: Shielded twisted pair cables are required for digital input/output/counter/analog input, and wiring should be done according to the terminal definition (see Tables 33-36 for details). The shielding layer should be single ended (controller side) or grounded at both ends (counter).

2. Start the process

Hardware installation and wiring: confirm power polarity, shield grounding, and terminal fastening;

Programming tool connection: Connect PADT (PC+programming tool) through Ethernet port, configure IP address (default 192.168.0.99);

Project configuration: Load or create a project, configure I/O channels, counter modes, communication protocols, and fault response logic;

Download and Start: Download the configuration to the controller, set the module mode to Run, perform a cold start, and the controller enters the RUN state (LED indicator light RUN is always on);

Troubleshooting: If the startup fails, locate the problem (such as configuration mismatch, wiring error) through LED status and programming tool diagnostic logs.

Operation and maintenance

1. Running operation

No manual intervention is required during normal operation, and the status is monitored through LED indicator lights and programming tools;

Forcing: Supports global/local forcing, requires authorization activation, can set time limits, and automatically resets after restart;

Diagnostic function: Read diagnostic logs (including fault time, type, and channel) through SILworX/ELOP II Factory, supporting fault filtering and export.

2. Maintenance points

Regular maintenance: The analog input module is calibrated every 10 years, and the fan (if any) is replaced regularly;

Fault handling: When the OS version ≥ 6.42 fails, it will automatically restart. If the fault is repeated within 1 minute, it will enter the STOP_INVALID state (output power loss); OS<6.42 version directly enters the ERROR STOP state;

Operating system upgrade: Load the new version of OS through programming tools, and place the controller in STOP state before upgrading;

Replacement and scrapping: When a module fails, it needs to be replaced as a whole (only repairable by the manufacturer), and scrapping must comply with environmental requirements. A disposal agreement can be signed with HIMA.

Applicable scenarios and core advantages

1. Typical applications

Safety interlock systems for industries such as petrochemicals, electricity, pharmaceuticals, and automobile manufacturing;

Emergency shutdown (ESD), equipment safety door monitoring, safety light curtain linkage, pressure/temperature over limit protection;

Safety control in Zone 2 hazardous environments (such as gas stations and chemical workshops);

Equipment control for underwater production platforms (F35 012 series).

2. Core advantages

High integration: Compact design integrates 24DI+8DO+2 counters+8AI, saving installation space;

High safety: SIL 3 certification, automatically switches to a safe state in case of failure, supports channel level fault diagnosis;

Environmental adaptability: covering a temperature range of 0-60 ℃/(-20~60 ℃), suitable for conventional/low temperature/underwater/hazardous environments;

Flexible expansion: support multiple communication protocols and wiring variants, and adapt to different sensor/actuator types.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923