K-WANG

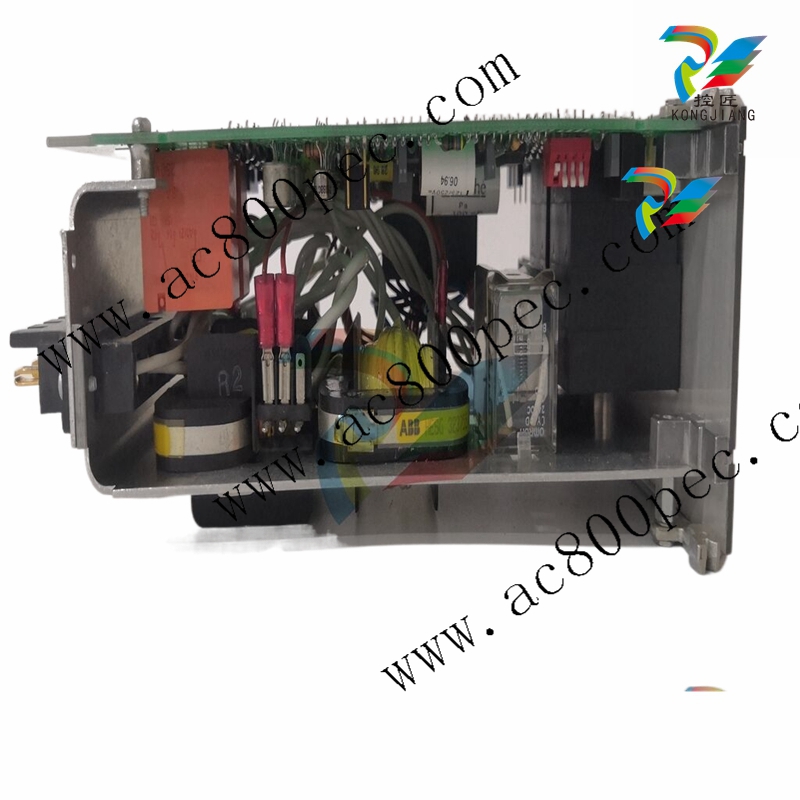

ABB IT94-3 HESG440310R2 HESG112699/B

ABB IT94-3 HESG440310R2 HESG112699/B

conserve energy ,reduce emissions

At present, energy conservation issues have attracted increasing attention from more and more countries. People are becoming increasingly concerned

Pay attention to the relationship between energy waste and environmental pollution, and recognize the adoption of technological methods to achieve it

Energy saving now.

Because pumps rarely operate at full load, using a frequency converter to control their speed can increase efficiency

Significantly reduce energy consumption. The energy required to operate the pump is basically the cube of the motor speed

Directly proportional, that is, slightly reducing speed can save a lot of energy. Pump running at half speed

The energy consumption is only one eighth of that of a pump running at full speed.

By using a frequency converter instead of throttling or damping devices, or inlet guide vanes,

The energy consumption of the pump can be reduced by up to 60% (please refer to the figure on page 4 for different control methods)

The energy consumption of the law. In addition, power frequency converters also help reduce CO2 emissions.

Reduce maintenance costs and extend equipment lifespan

The frequency converter can also serve as a soft starter to reduce stress on the power grid, motor, and pump. stay

During the start-up process, the frequency converter can gradually increase the speed of the motor and stabilize it according to the load

Speed up the ground. A frequency converter can start several pumps in sequence.

Soft start can eliminate high starting current and voltage drop, which can cause jumping

Lock. By using soft start, maintenance costs can be reduced and equipment lifespan can be extended.

If the pump is turned off or the water demand decreases, the frequency converter can gradually reduce the pump speed,

Avoiding water hammer effects. The reduction of stress on the pump helps to extend its service life.

ABB can provide a complete set of applications with a power range of 315 kW to over 100 MW

Medium voltage frequency converter and soft starter.

ACS 1000 (315 kW – 5 MW, up to 4.16 kV)

The ACS 1000 medium voltage frequency converter is an unparalleled solution for pumping stations in the water industry

Plan. Due to its unique sine wave output filter, it eliminates common mode voltage and voltage inversion

The ACS 1000 is suitable for any new or existing standard motor. ACS 1000i is

A fully integrated standard frequency converter, comprising an input transformer and an input contactor.

ACS 2000(250 – 2600 kW,4.0 – 6.9 kV)

ACS 2000 is suitable for modified applications and new standard induction voltages up to 6.9 kV

Machine. It does not require the use of an input isolation transformer, so it can be directly connected to the power grid (direct)

It can be equipped with an integrated transformer or connected to an external input isolation transformer.

ACS 2000 can also be used for four quadrant operation to achieve energy regeneration and reactive power compensation.

Universal frequency converters provide simple and reliable motor control for applications such as fans and pumps.

ACS 5000(2 – 32 MW,6.0 – 6.9 kV)

ACS 5000 is suitable for standard induction motors and synchronous motors with voltages up to 6.9 kV.

The ACS 5000 is ideal for high-power pump applications with voltage levels ranging from 6.0 to 6.9 kV

choice. The use of ACS 5000 to retrofit these pumps will significantly improve efficiency and reliability. empty

The cold type ACS 5000 can also be equipped with an integrated transformer.

ACS 6000 (3-27 MW, up to 3.3 kV)

ABB's ACS6000 is a modular frequency converter suitable for both synchronous and inductive electrical applications

High performance single or multiple motor applications for machines. ACS 6000 can be equipped with 12/24 pulse diodes

Rectifiers or IGCT active rectifier units to reduce or even eliminate grid harmonics

Wave. ACS6000 is an ideal choice for large pumping stations and applications with strict requirements for power grid conditions

choice.

MEGADRIVE LCI (2-72 MW, or higher power as needed)

ABB's MEGADRIVE LCI is the best solution for high voltage and high power pump applications

The case is applicable to the fields of irrigation and water transportation. They can also be used as soft starters for multi pump applications

The device. Equipment with a power range of 72 MW adopts standardized design, with a power exceeding 100 MW

MW's equipment adopts engineering design.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

BENTLY NEVADA 3500/15 133292-01 Power Supply Module

-

ABB PM877 3BDH000777R1 Central_Unit Controller

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor