K-WANG

HIRSCHMANN MACH1040 Series Full Gigabit Industrial Ethernet Reinforced Switch

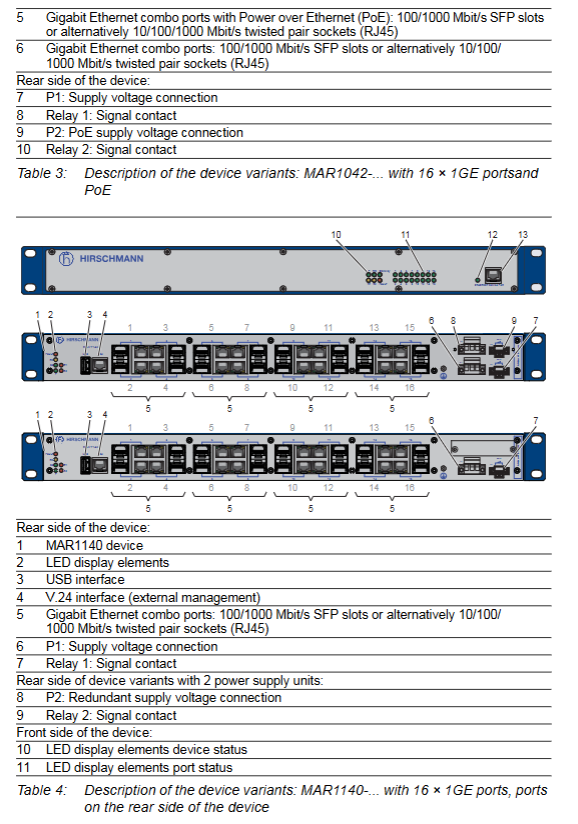

Model difference 1. MAR1040: Front end port, no PoE, supports redundant power supply (optional)

2. MAR1042: Front end port, 4 PoE ports, dual power supply units (including PoE power supply)

3. MAR1140: Backend port, additional Fast Ethernet diagnostic port at the front end, no PoE

4. MAR1142: Backend port, front-end diagnostic port, 4 PoE ports

Core function 1. Ports: 16 Gigabit combination ports (choose one of SFP slot/RJ45, automatically disable RJ45 when inserting SFP)

2. PoE: MAR1042/MAR1142 supports IEEE 802.3af, with a maximum of 15.4W per port, and ports 1-4 are PoE ports

3. Redundancy: Loop network redundancy (HIPER Ring), redundant power supply (some models)

4. Management: Web, Telnet, HiView, Industrial HiVision, V.24 (local), USB (configuration backup)

HIRSCHMANN MACH1040 Series Full Gigabit Industrial Ethernet Reinforced Switch

Product Core Information

Category key content

Product positioning: Industrial Ethernet reinforced switch, compliant with IEEE 802.3 standard, fanless design, suitable for extreme industrial environments

Model difference 1. MAR1040: Front end port, no PoE, supports redundant power supply (optional)

2. MAR1042: Front end port, 4 PoE ports, dual power supply units (including PoE power supply)

3. MAR1140: Backend port, additional Fast Ethernet diagnostic port at the front end, no PoE

4. MAR1142: Backend port, front-end diagnostic port, 4 PoE ports

Core function 1. Ports: 16 Gigabit combination ports (choose one of SFP slot/RJ45, automatically disable RJ45 when inserting SFP)

2. PoE: MAR1042/MAR1142 supports IEEE 802.3af, with a maximum of 15.4W per port, and ports 1-4 are PoE ports

3. Redundancy: Loop network redundancy (HIPER Ring), redundant power supply (some models)

4. Management: Web, Telnet, HiView, Industrial HiVision, V.24 (local), USB (configuration backup)

Safety installation requirements

Personnel qualifications: Only trained and qualified personnel are allowed to operate, and they need to understand electrical hazards and protective measures

Installation environment:

Only installed in switch cabinets or restricted access areas, desktop use is prohibited

Vertical installation requires a fire-resistant enclosure (IEC/EN 62368-1)

19 inch cabinet installation requires load-bearing rails, with a distance of ≥ 5cm between the top and bottom of the equipment (for heat dissipation)

For use in hazardous environments (Class 1, Division 2), temperature code T4 (-30 ° C~+70 ° C) must be met, and the USB port must be locked when in use

Electrical safety:

Power supply: It must match the equipment nameplate (L-type 24-48VDC, M-type 100-240VAC/110-250VDC), and the cross-sectional area of the power cord must be ≥ 1mm ² (AWG16)

Grounding: Priority grounding, grounding wire cross-section ≥ 1.0mm ² (AWG16), grounding screw connected to protective conductor

Wiring: Cables must be resistant to tensile stress and comply with DIN VDE 0100-520 standard. Signal contacts should use 0.5-3.0mm ² copper wires

Installation process

Pre inspection: Confirm that the packaging includes equipment, brackets (2 pre installed), power terminal blocks (1-2), signal contact terminal blocks (1-2), safety instructions, and no transportation damage

Optional steps: Install HIRSCHMANN compatible SFP optical module (remove protective cap, insert slot into snap lock)

Wiring operation:

Power supply wiring: Connect protective conductors, positive/negative (DC) or phase/neutral (AC) wires according to the terminal definition, with a torque of 0.51Nm (North America)

Signal contact wiring: 2-core terminal block, torque 0.34Nm (North America), ensure that the cable has no voltage

Equipment fixation:

Cabinet installation: Use sliding rails and secure with side bracket screws

Wall installation: Adjust pre installed brackets, install additional brackets (accessories), fix with screws

Grounding operation: Connect the protective conductor through the independent grounding screw on the back of the device, and prioritize grounding over other cable connections

Data connection:

Twisted pair cable: Cat5e cable up to 100m, shielded cable (SF/UTP) suitable for strong interference environments

Fiber optic: SFP modules need to be matched (SX/LX/LH, etc.) and interconnected with ports of the same type (such as SX-SX)

Configuration and Management

Initial setup:

IP configuration methods: DHCP (default), BOOTP, V.24 interface input AutoConfiguration Adapter

First login: The default password (admin/private, read/write permissions) must be changed; user/public, Read only permission), the new password must contain uppercase and lowercase letters, numbers, and special characters (≥ 8 digits)

Default parameters:

Port: auto negotiation enabled, 100M optical port defaults to full duplex, PoE ports are 1-4

Redundancy: Ring network redundancy disabled, control port 4, coupling port 3

V. 24 interfaces: 9600 baud rate, 8 data bits, 1 stop bit, no checksum, no handshake

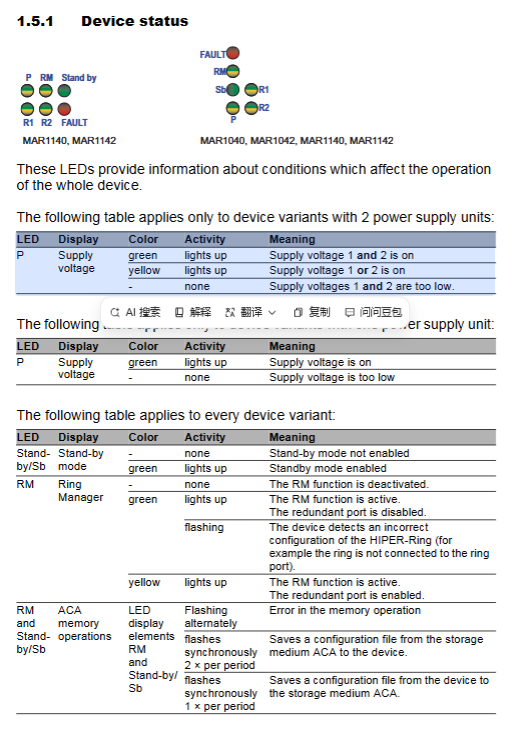

Status monitoring:

LED indication: device status (power supply, fault, ring network, standby), port status (connection, data transmission, disabled)

Temperature monitoring: The ambient temperature should be below the upper limit of the technical parameters, and the internal temperature of the equipment should be higher than the ambient temperature

Key technical parameters

Project specification details

Physical dimensions without bracket: 448 × 345 × 44mm; with bracket: 463 × 345 × 44mm

Weight base model: ≤ 4.2kg; redundant power supply: ≤ 4.4kg; PoE model: ≤ 4.6kg

Power supply parameters L-type: 18-60VDC, backup fuse 6.3A (slow melting); M-type: 90-265VAC/77-300VDC, backup fuse 2.5A (slow melting)

Signal contact non hazardous environment: Umax 230VAC/30VDC, Imax 2A; Dangerous environment: Umax 30V, Imax 90mA

Environmental extreme working temperature: standard 0~60 ° C, extended -40~70 ° C; storage temperature: -40~85 ° C; humidity 5% -95% (no condensation)

certification standard CE(EMC/RoHS)、UKCA、FCC Class A、UL 508、ISA 12.12.01(Class I Div.2)、EN 50155( Rail Transit)

Maintenance and disassembly

Daily maintenance:

Regularly check whether the ventilation duct is unobstructed and the relay contact resistance (according to the switching frequency)

Dismantling process:

Device removal: Disconnect data cable → Turn off power → Disconnect grounding → Remove bracket screws

SFP removal: Open locking mechanism → Pull out module → Cover with protective cap

Troubleshooting: In case of equipment damage/malfunction, turn off the power and return to Hirschmann for inspection. Do not open the cover by yourself (only authorized personnel can operate)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923