K-WANG

WAGO series molded case circuit breaker (MCCB)

Core function of the product: As a key protective component of low-voltage distribution networks, it can detect and disconnect faults such as overload, short circuit, and grounding faults, and protect the safety of circuits and electrical equipment.

WAGO series molded case circuit breaker (MCCB)

Product Scope and Manual Positioning

1. Product details for adaptation

Clearly cover the specific series of WAGO molded case circuit breakers, list the core compatible models (including sub models with different rated currents and breaking capacity levels), and label the product application scenario boundaries (such as industrial distribution, building power supply, and other low-voltage distribution systems).

Core function of the product: As a key protective component of low-voltage distribution networks, it can detect and disconnect faults such as overload, short circuit, and grounding faults, and protect the safety of circuits and electrical equipment.

2. Core purpose of the manual

Target audience: Electrical installation personnel, maintenance technicians, equipment management personnel (with corresponding electrical qualifications).

Core value: Provide standardized and compliant operating basis, avoid equipment damage, electric shock, fire and other safety risks caused by installation errors, improper operation, and maintenance deficiencies, while ensuring stable product performance.

Important statement: The manual specifies the minimum requirements for safe use of the product, which must be implemented in conjunction with the on-site distribution system specifications and local electrical regulations; After the manual is revised, the latest version shall prevail, and the content of the old version shall automatically become invalid.

Safety Warning and Basic Requirements

1. Core security warning

Electrical safety: All operations must be carried out after power failure, and it is necessary to confirm that there is no residual voltage in the circuit (using professional electrical inspection tools). Live installation, wiring, or disassembly are prohibited.

Protection requirements: Insulated gloves, goggles and other protective equipment should be worn during operation to avoid injuries caused by electric arc burns and metal debris splashes.

Prohibited scenarios: It is strictly prohibited to modify the core components of circuit breakers (such as release devices and arc extinguishing chambers); It is strictly prohibited to use beyond the rated parameters (current, voltage, breaking capacity); It is strictly prohibited to operate in non-standard environments such as humidity, corrosion, and excessive dust.

Responsibility statement: The manufacturer shall not be held responsible for any equipment malfunctions or safety accidents caused by failure to comply with the manual requirements.

2. Basic usage prerequisites

Personnel qualifications: Operators and maintenance personnel must have low-voltage electrical operation qualifications, be familiar with the principles of power distribution systems and the working mechanism of circuit breakers.

Environmental requirements: Clearly define the environmental conditions for product operation, with a temperature range typically between -5 ° C and 40 ° C, humidity ≤ 95% (no condensation), and altitude ≤ 2000m (reduced capacity is required for use beyond altitude); Keep away from flammable, explosive, strong magnetic fields, and strong vibration sources.

Equipment inspection: Before installation, it is necessary to confirm that the appearance of the circuit breaker is not damaged, the accessories are complete (such as release, operating handle, wiring terminal), and the product nameplate parameters are consistent with the actual usage requirements.

Installation specifications and operating procedures

1. Preparation before installation

Tool preparation: Professional tools such as torque wrenches, crimping pliers, and insulation stripping pliers are required, and the insulation performance of the tools must meet safety standards.

On site inspection: Confirm that the installation plate at the installation location has sufficient strength (able to withstand the weight of the circuit breaker and the electric force during short circuit), and that the installation surface is flat and free of debris; The specifications of the distribution line should match the rated current of the circuit breaker (the wire cross-section and material should meet the requirements).

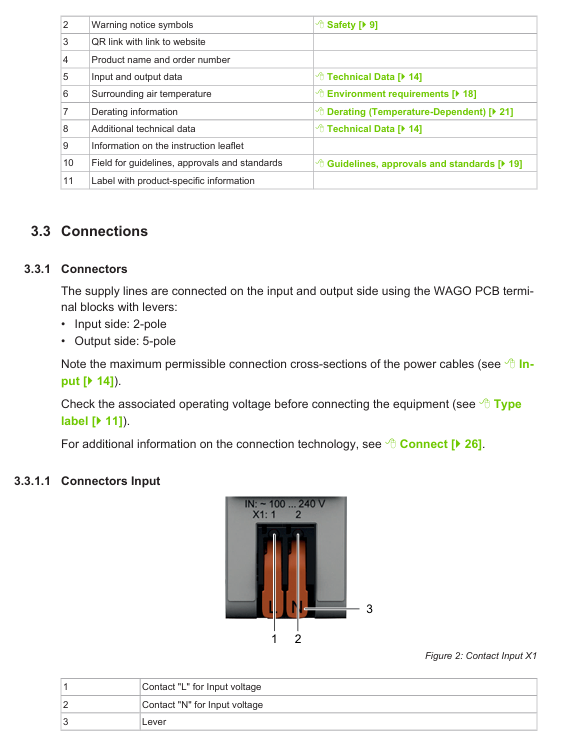

2. Specific installation process

Fixed method: The circuit breaker is fixed to the mounting plate with bolts, and the bolt torque must comply with the manual regulations (different models correspond to different torque values) to avoid loosening and vibration during operation.

Wiring requirements:

The direction of incoming and outgoing wires should follow the manual markings (reverse wiring is not allowed), and the length of wire stripping should match the depth of the terminal to avoid short circuits caused by exposed conductors being too long.

When tightening the wiring terminals, it is necessary to operate according to the specified torque to prevent excessive looseness from causing excessive contact resistance and heating, or excessive tightening from damaging the terminals.

Multi core wires require the use of crimping terminals, and it is prohibited to directly insert multi stranded wires into the terminal holes.

Attachment installation: If auxiliary contacts, undervoltage release and other accessories need to be installed, they must be connected correctly according to the wiring diagram to ensure that the accessories match the main function of the circuit breaker. After the wiring is completed, the reliability of the accessory action needs to be checked.

3. Check after installation

Mechanical inspection: Manually operate the circuit breaker to close and open, and the action should be smooth without any jamming. The handle position should be clear (with clear identification of the closing, opening, and energy storage status).

Electrical inspection: Confirm that the wiring is not loose, the phase sequence is correct, and the insulation resistance test is qualified (using a 500V megohmmeter, insulation resistance value ≥ 1M Ω).

4. Operating instructions

Closing operation: After ensuring that there are no faults in the circuit, manually turn the handle to the "closing" position, and hear a "click" sound to indicate that the closing is in place; If equipped with an electric operating mechanism, press the control button to complete the closing and observe that the mechanism operates normally.

Opening operation: When opening normally, turn the handle to the "opening" position. After the fault is opened, the fault needs to be checked first, and the release device needs to be reset before closing.

Release adjustment:

Overload release: Adjust the set current within the range specified in the manual based on the load characteristics of the line (not exceeding the rated current of the circuit breaker) to ensure delayed release in case of overload.

Short circuit release: The instantaneous release setting current is adjusted according to the calculated value of the short-circuit current in the distribution system, ensuring quick disconnection during a short circuit and avoiding the expansion of the fault.

Ground fault release (if equipped): Adjust the ground fault action current and delay, and coordinate with system protection.

Maintenance and upkeep requirements

1. Daily maintenance cycle

Regular inspection: Under normal operating conditions, conduct a routine inspection every 6 months; In harsh environments (high dust, high humidity, frequent operation), reduce to once every 3 months.

Annual maintenance: Conduct comprehensive maintenance once a year, synchronized with power outage maintenance of the distribution system.

2. Maintain projects and operations

Appearance inspection: Check whether the circuit breaker casing and operating handle are damaged or discolored, and whether there are any signs of heating on the terminals (such as oxidation or burnt black).

Mechanical performance inspection: Operate the closing and opening of the circuit several times to check whether the action is smooth and whether the tripping mechanism is sensitive; The energy storage mechanism (if any) can reliably maintain energy after storage and act quickly when released.

Electrical performance inspection:

Measure insulation resistance to ensure there is no insulation aging or moisture damage.

To check the accuracy of the release action, it can be tested by simulating overload and short circuit conditions (professional equipment is required, and blind testing on site is prohibited).

Cleaning requirements: Use a dry brush or compressed air (pressure ≤ 0.4MPa) to remove dust from the surface and terminals of the circuit breaker. It is prohibited to use wet cloths or organic solvents for cleaning.

3. Maintain taboos

Non professionals are prohibited from disassembling core components such as circuit breakers, arc extinguishing chambers, and release devices. Disassembling them will cause the product to lose its protective function and cannot guarantee sealing.

It is prohibited to change the setting parameters of the release during maintenance (unless there is a clear load adjustment requirement and it is operated by professional personnel).

During the maintenance process, it is necessary to cut off power throughout the entire process and hang a "under maintenance, no closing" sign to prevent others from making mistakes.

Troubleshooting and Solutions

1. Common faults and their solutions

Possible causes and solutions for the fault phenomenon

Unable to close 1. The fault has not been resolved and the release has not been reset; 2. The operating mechanism is stuck; 3. The auxiliary contacts have not been reset; 4. Power failure of electric operating mechanism: 1. Check for short circuit and overload faults, and manually reset the release; 2. Check if there are any foreign objects in the organization, clean them and test them; 3. Check the auxiliary contact wiring and repair the poor contact of the contacts; 4. Check the power supply of the operating mechanism and restore power supply

Wrong tripping (tripping when there is no fault) 1. Overloaded tripping device setting current is too low; 2. There is harmonic interference in the line; 3. The release device is damaged; 4. Excessive ambient temperature leads to misoperation of the release device. 1. Adjust the setting current again according to the actual load current; 2. Investigate harmonic sources and install filtering devices if necessary; 3. Replace the damaged release device; 4. Improve ventilation conditions and reduce environmental temperature

Opening failure: 1. Operating mechanism failure (such as spring failure or jamming); 2. The release device is damaged; 3. Loose wiring causes the mechanism to fail to interlock. 1. Disassemble and inspect the mechanism, replace the faulty spring, or clean any stuck foreign objects; 2. Replace the release device; 3. Tighten the wiring to ensure normal linkage of the mechanism

Terminal heating: 1. Loose wiring; 2. The cross-sectional area of the wire is too small; 3. Terminal oxidation or poor contact: 1. Re tighten the terminal according to the specified torque; 2. Replace the wires that meet the requirements; 3. Clean the terminal oxide layer and replace the terminal if necessary

Abnormal noise of circuit breaker: 1. Loose installation leads to vibration; 2. Wear or looseness of institutional components; 3. Electromagnetic noise during overload operation: 1. Re tighten the circuit breaker to enhance installation stability; 2. Check the components of the mechanism, replace worn parts, and tighten loose parts; 3. Investigate the cause of overload and reduce the load to the rated range

2. Fault handling principles

Before the fault is thoroughly investigated, it is forbidden to forcefully close the switch to avoid expanding the scope of the fault or causing safety accidents.

If the circuit breaker experiences serious malfunctions such as damage to the arc extinguishing chamber, deformation of the outer shell, or burning of internal parts, maintenance is prohibited and the circuit breaker of the same model must be replaced directly.

After troubleshooting, action testing and electrical performance testing are required to confirm that there are no issues before resuming operation.

Technical parameters and compliance statement

1. Core technical parameters

Rated parameters: Clearly define key parameters such as the rated voltage (e.g. AC 400V/690V), rated current (e.g. 100A~630A), rated breaking capacity (e.g. Icu=50kA), and rated short-time withstand current (Icw) of the circuit breaker.

Release parameters: overload release setting current range, short-circuit release setting current level, ground fault release action current and delay range.

Mechanical parameters: number of operations (mechanical life, electrical life), closing time, opening time, etc.

2. Compliance and Usage Restrictions

Compliance standards: The product complies with international and domestic industry standards such as IEC 60947-2 and GB 14048.2, and has passed relevant certifications (such as CE certification).

Usage restrictions: Clearly state that the product is not suitable for special environments (such as strong corrosion, strong radiation, explosion-proof scenarios). If it needs to be used in special scenarios, a dedicated model must be selected.

Warranty Statement: The product warranty period shall be executed in accordance with the manufacturer's regulations, and the warranty scope does not include damage caused by improper operation or maintenance.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923