K-WANG

ABB MNS iS Motor Control Center System

ABB MNS iS Motor Control Center System

Product positioning: MNS iS is an intelligent motor control center upgraded based on MNS series technology, integrating protection, control, and monitoring functions, suitable for industrial production lines, energy facilities, and other scenarios. Through modular design, it achieves efficient operation and maintenance as well as full lifecycle cost optimization.

Core characteristics and values of the system

1. Core advantages

High safety: The power and control areas are physically isolated, complying with the IEC 61439 series standards, supporting arc fault protection (up to 100 kA/300 ms), ensuring the safety of personnel and equipment.

Standardization and flexibility: The fully pre installed power module (MStart) supports multiple starter types (direct start, star delta start, etc.), and the control module (MControl) can expand its functionality through software configuration without the need for additional hardware.

Low lifecycle cost: Reduce downtime through predictive maintenance (condition monitoring), standardize modules to lower inventory requirements, and simplify troubleshooting processes.

Intelligent information management: integrates web servers with industrial communication protocols (Profibus, Profinet, etc.), supports remote monitoring and data analysis, and achieves digital operation and maintenance.

2. Innovative design

Functional module separation: The power module (MStart) and control module (MControl) operate independently, supporting live module replacement and improving system availability.

Transformer free sensing technology: high-precision shunt sensors are used to measure current, voltage, and temperature, replacing traditional transformers and reducing energy consumption and space occupation.

Plug and play architecture: modules automatically identify location and type, communication networks automatically configure, reducing engineering complexity.

System Architecture and Components

1. Hardware composition

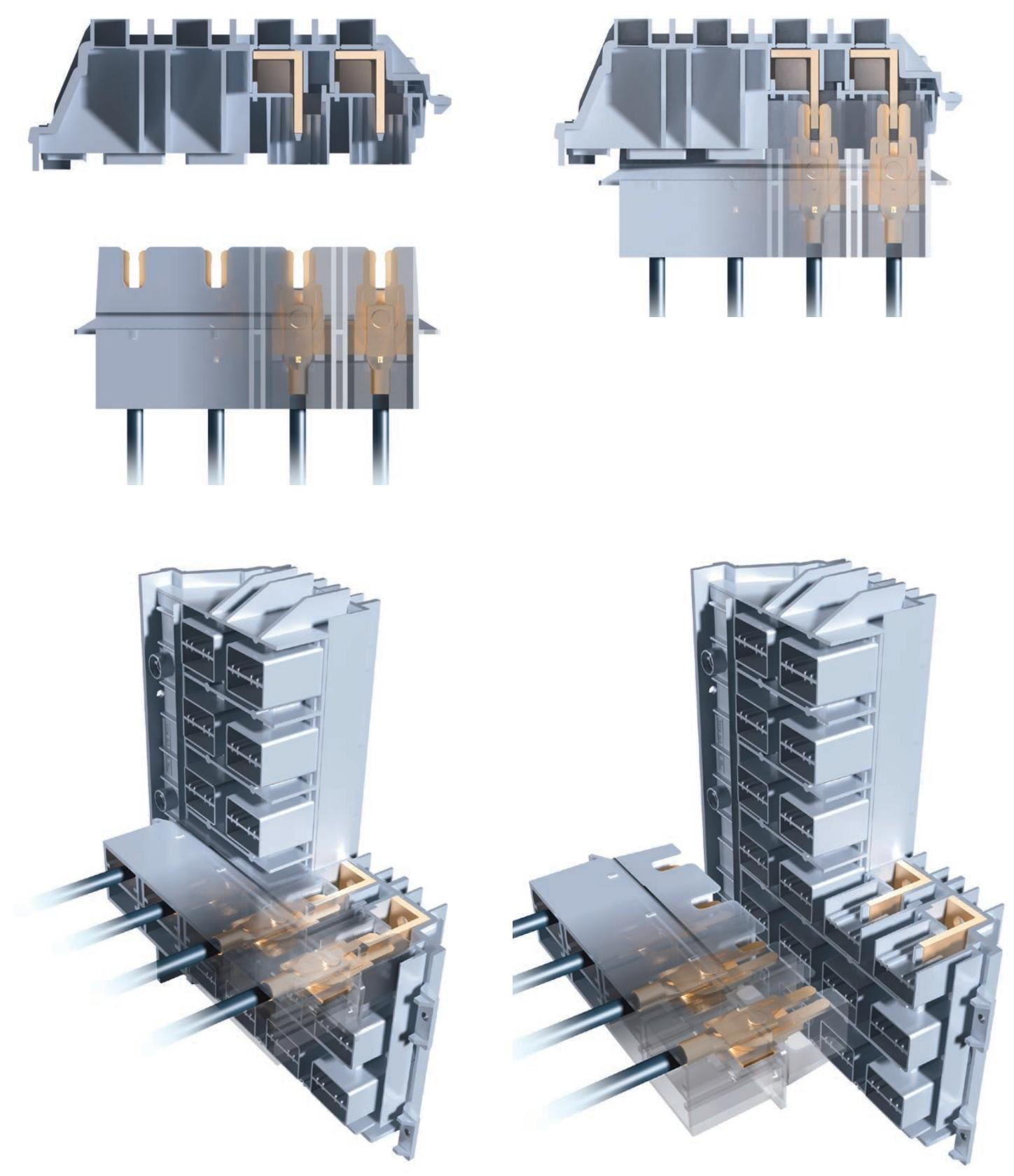

Power module (MStart):

Includes isolators, short-circuit protection devices (fuses or circuit breakers), contactors, and sensor modules.

Supports drawer style (6E/4 to 24E sizes) and fixed style (suitable for motors ≥ 250 kW) installation, compatible with voltage levels of 400 V, 500 V, and 690 V.

Control module (MControl):

The core controller is responsible for protecting algorithms (overload, phase loss, ground fault, etc.), logic control, and data acquisition.

Support the expansion of I/O interfaces (digital, analog, PTC/PT100 temperature input) to meet different on-site signal requirements.

Communication and Interface Module:

MLink: As a gateway connecting upper level systems, it supports protocols such as Profibus DP, Profinet, Modbus, and has a built-in web server.

MView: Local Human Machine Interface (HMI), supports touch operation and status monitoring, and can be accessed remotely through the network.

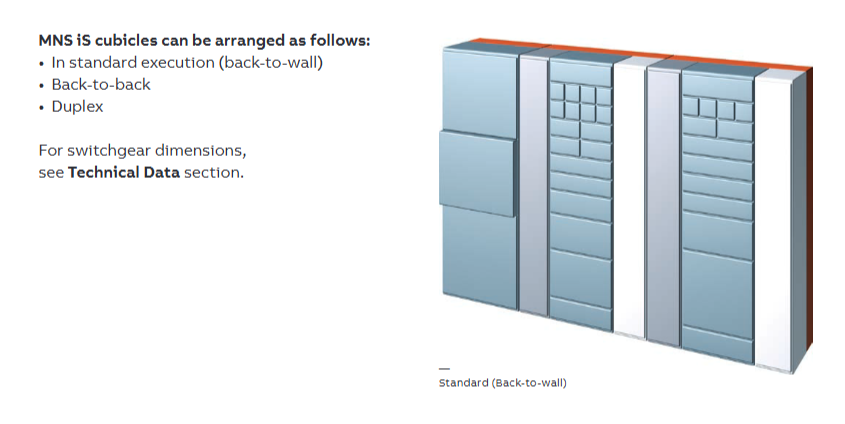

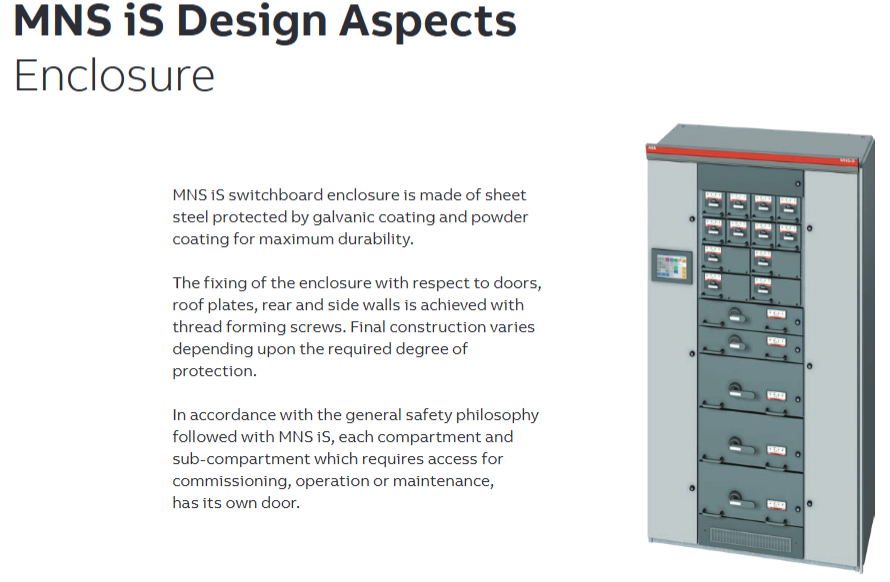

2. Structural design

Partition separation: Vertical and horizontal partitions strictly distinguish equipment areas, control cable areas, power cable areas, and busbar areas to avoid electromagnetic interference, and support different key lock control access permissions.

Busbar system: The main busbar is located at the rear of the cabinet and adopts a maintenance free design (copper material, optional silver plating or insulation sleeve). It is safely isolated from the equipment area through a multifunctional isolation wall (MFW).

Cable management: Power and control cable partition wiring, supporting up and down incoming lines, suitable for different installation scenarios.

Control and protection functions

1. Protection function module

Thermal Overload Protection (TOL): Based on the IEC 60947-4-1 standard, it calculates the motor's thermal capacity, provides "trip time" and "reset time" warnings, and supports ATEX certification scenarios.

Motor abnormal protection: monitors phase loss, current imbalance, undervoltage, grounding faults, etc., and can be configured with alarm or trip actions.

Process monitoring and protection: including blockage, underload, no-load, and limit of starting times, to prevent mechanical failures (such as pump cavitation).

2. Maintenance and status monitoring

Predictive maintenance: Monitor parameters such as the number of contactor actions, module insertion times, operating hours, and contact temperature, and trigger an alarm when the threshold is exceeded.

System self diagnosis: Automatically verify module type and position matching, communication status, and control voltage to ensure system integrity.

Communication and Integration

Communication architecture and core components

1. Communication nodes and hierarchy

The communication system of MNS iS adopts a distributed architecture and is divided into three levels of nodes:

On site level: With MControl as the core, responsible for the protection, control, and data acquisition of a single motor, communicating with the power module (MStart) through an internal bus.

Network level: Multi node aggregation is achieved through MLink gateway, supporting interaction with upper level systems, and can connect up to 60 MControl modules.

Monitoring level: Integrated MView local human-machine interface and web server, supporting remote access and configuration.

2. Key communication components

Component Function Description

MControl has a built-in communication interface that supports real-time data exchange with MStart modules (current, temperature, status, etc.) and can be directly connected to Profibus DP/Profinet networks.

As a system gateway, MLink supports protocols such as Profibus DP, Profinet, Modbus RTU/TCP, OPC, etc., enabling integration with PLC, SCADA and other systems, while also providing web server functionality.

MView local touch panel (optional), displaying motor status, alarm information, and operation buttons based on a web interface, supporting permission management.

Communication Protocol and Interface

1. Supported protocol types

Industrial bus protocol:

Profibus DP/DP V1 (slave mode, supporting process data and diagnostic information transmission);

Profinet I/O (compatible with ABB systems and supports real-time communication);

Modbus RTU (serial communication) and Modbus TCP (Ethernet communication).

General Agreement:

Built in web server, supporting access to monitoring interface through standard browsers;

OPC interface, easy to integrate with third-party SCADA or MES systems;

NTP (Network Time Protocol) enables system wide time synchronization.

2. Data transmission capability

Internal communication: A 10 Mbps real-time bus is used between MControl and MLink, with a command response time of approximately 2 ms for a single MControl and a total system response time of ≤ 258 ms for 60 nodes.

External interaction:

The maximum transmission rate of Profibus DP is 12 Mbps;

Profinet and Modbus TCP support 100 Mbps Ethernet transmission;

Support data block read and write (such as motor current, temperature, tripping reasons, etc.) and remote control commands (start/stop/reset).

System integration capability

1. Integration with upper level systems

Process Control System (PCS): Using MLink as a gateway, the motor status and measurement values (current, power, energy consumption) are uploaded to PLC or DCS, and control instructions are received to achieve remote operation.

Electrical network monitoring system: supports sending electrical parameters (such as harmonics and power factor) to the energy management system (EMS) to assist in energy optimization.

Maintenance management system: Push equipment health data (contactor action frequency, operating hours, temperature trend) to CMMS (computerized maintenance management system) through OPC interface, supporting the development of predictive maintenance plans.

2. Redundancy and reliability design

Dual redundant communication: supports two independent communication paths (primary/backup MLink). When the primary link fails, it automatically switches to the backup link to ensure uninterrupted operation, with a switching time of ≤ 100 ms.

Communication fault protection: Configure the "fail safe" mode (such as keeping the motor running/stopping in case of communication interruption) to avoid unexpected shutdowns caused by network issues.

Time synchronization and data consistency

Synchronization mechanism: Implement system wide time calibration through NTP protocol, support access to factory level time servers (such as GPS synchronization sources), and ensure that the timestamp accuracy of event records (alarms, trips) is ≤ 1 ms.

Data timeliness: The update cycle of key measurement values (such as current and temperature) can be configured (default 100 ms) to meet real-time monitoring requirements; Historical data (energy consumption, number of actions) is stored at the minute level and supports trend analysis.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923