K-WANG

GE Multilin 889 Generator Protection System

GE Multilin 889 Generator Protection System

Product Overview

Core functions

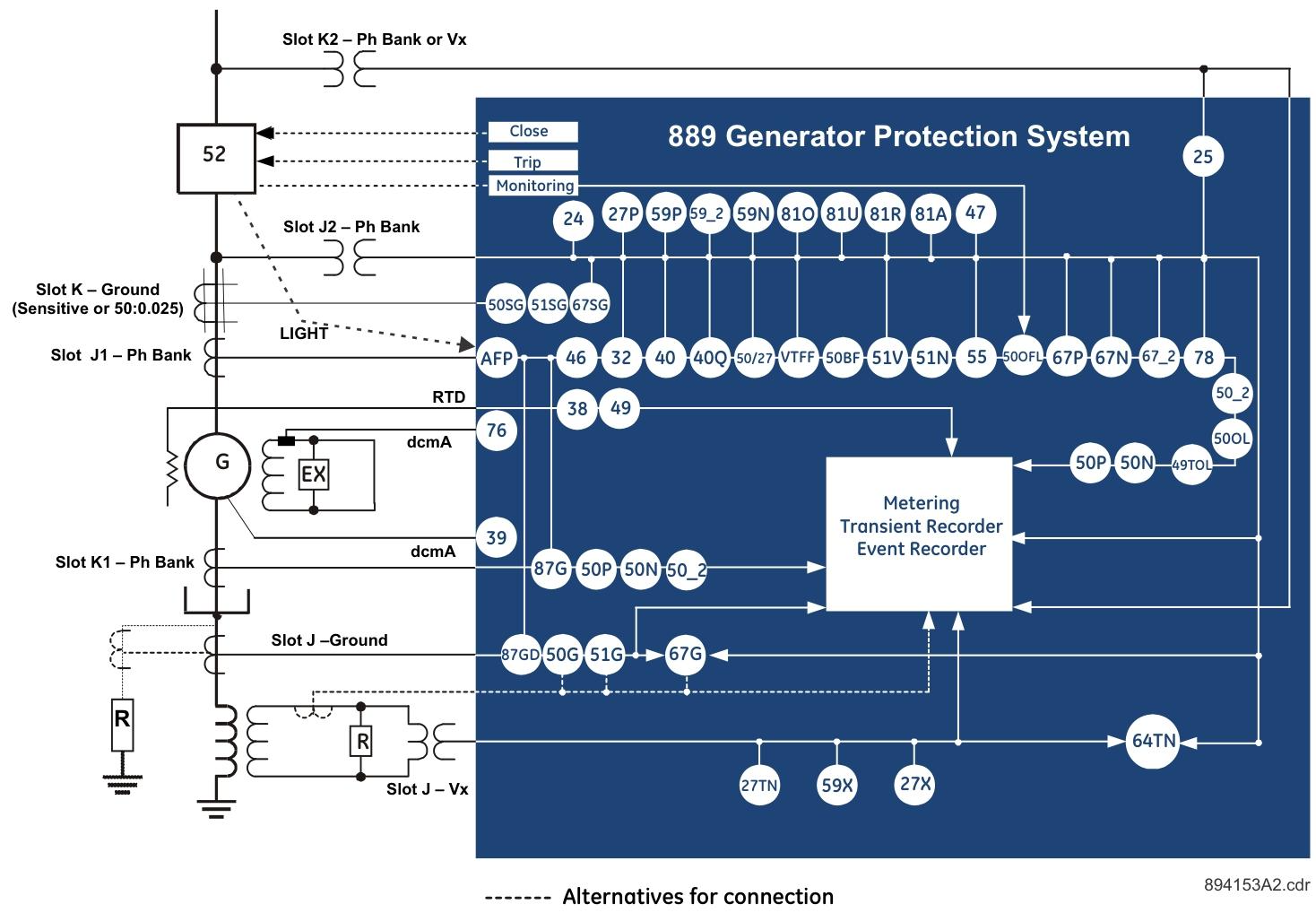

The 889 generator protection system is a microprocessor based device used for primary and backup protection of small and large generators, with protection, control, and asset monitoring functions. It can monitor the imbalance, differential, overexcitation, demagnetization and other states of the generator, and meet different industry standards and user needs through flexible configuration.

main features

Protection function: covering various protection elements such as percentage differential protection, overcurrent, overvoltage/undervoltage, frequency abnormality, demagnetization, reverse power, etc. (see ANSI equipment numbering table for details).

Flexibility: Supports custom logic (FlexLogic), programmable curves (FlexCurve), multiple sets of setpoints, and default settings simplify initial configuration.

Monitoring and recording: Real time monitoring of parameters such as current, voltage, and power, with functions such as event recorder (1024 events), transient recorder (waveform capture), and fault report (15 events).

Communication capability: Supports multiple protocols such as Modbus, DNP3.0, IEC 60870-5-103/104, IEC 61850, etc., with optional interfaces such as Ethernet, RS485, Wi Fi, etc.

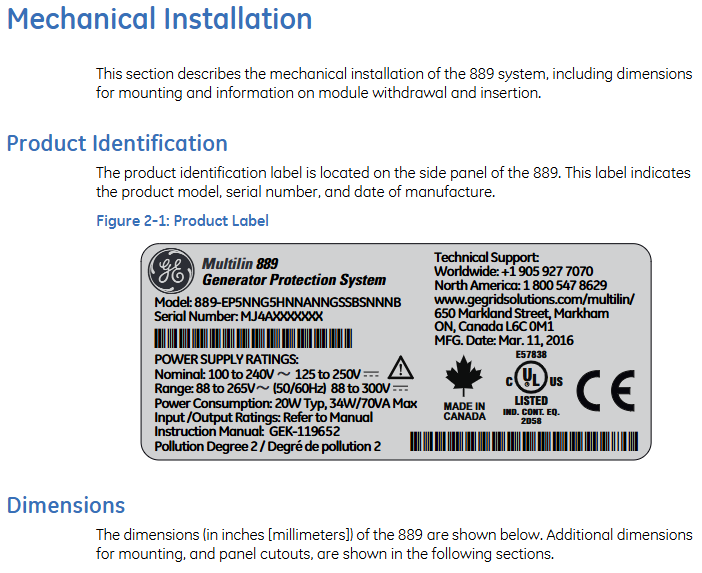

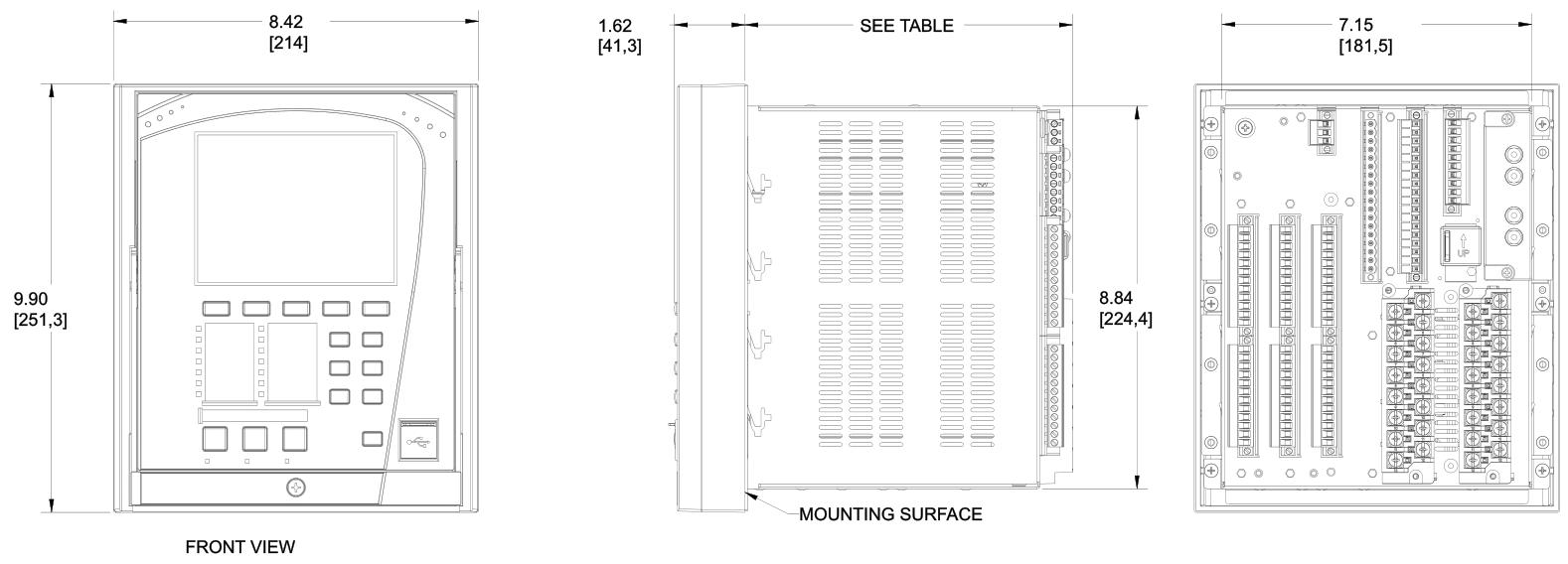

Installation instructions

1. Mechanical installation

Size and installation method: Supports standard panel installation, drawer installation, and can be matched with a depth reducing ring to adapt to narrow spaces; The full-size weight is about 9kg, and ventilation gaps need to be reserved at the top and bottom.

Key component installation: The power module and magnetic module (CT/VT) need to be plugged and unplugged according to the steps. Before removing the magnetic module, the system power must be disconnected and the CT secondary side short circuited to prevent high voltage hazards.

Installation of arc light sensor: The optical fiber should avoid bending with a radius less than 25mm, and the installation position should be unobstructed. It supports 4 point sensors and has a standard fiber length of 18 feet (maximum 32 feet).

2. Electrical installation

CT/VT connection: CT supports 1A/5A secondary, VT supports star/triangle connection, pay attention to phase sequence and polarity to ensure correct protection function.

Grounding requirements: The system rack, EMI shielding, and cables must be reliably grounded, and the grounding resistance of the intrinsic safety system must be<1 Ω.

Wiring specifications: The control power supply should match the rated range (such as 110-250V AC/DC), and the communication line should use shielded twisted pair. The maximum distance of RS485 is 1200 meters.

Interface Description

1. Front panel interface

Display screen and buttons: graphic LCD display, supports menu navigation (Targets, Status, Metering, etc.), 5 navigation keys+3 programmable function keys, 17 LEDs (including programmable status indication).

Operation function: It can view real-time data, set parameters, reset alarms, support single line diagram (SLD) display, and can configure default screens and color schemes.

2. Software interface (EnerVista 8 Series Setup)

Function: Used for configuring parameters, upgrading firmware, viewing records, drawing custom SLDs, etc., supporting online/offline operations.

Connection method: Connect via USB, Ethernet, Wi Fi, and configure communication parameters such as IP address and port.

Advanced features: SLD configurator (custom single circuit diagram), FlexCurve editor (custom protection curve), transient recorder (waveform analysis), etc.

Detailed explanation of core functions

1. Protection function

Differential protection: including generator stator differential (87G), overall differential (87O), supporting dual slope characteristics, 2nd/5th harmonic braking.

Overcurrent protection: including phase/neutral/ground overcurrent (50/51 series), supporting multiple inverse time curves (IEEE, IEC, etc.).

Voltage protection: Over/Under voltage (59/27 series), Negative sequence overvoltage (59_2), Voltage Hertz protection (24), etc.

Other protections: demagnetization (40), reverse power (32), abnormal frequency (81U/O/R), arc protection (AFP), etc.

2. Monitoring function

Real time monitoring: current, voltage, power, frequency, harmonics, temperature (RTD), etc., with an accuracy of ± 0.25% (current) and ± 0.5% (voltage).

Recording function: Event recording (timestamp accurate to microseconds), transient recording (waveform before and after fault), data log (configurable with 16 analog quantities).

3. Control function

Circuit breaker control: supports opening/closing, locking, and bypass, adopts the "select first, operate later" mechanism, and is compatible with local/remote control.

Synchronization check (25): Monitor voltage, frequency, and phase difference to ensure that the grid connection conditions are met.

Arc protection: Detecting arc light through fiber optic sensors, quickly triggering tripping, and reducing equipment damage.

Set point configuration

Device settings: including clock synchronization (IRIG-B, PTP, SNTP), security (user roles, password policies), and communication protocol parameters.

System settings: CT/VT parameters, generator rating, grounding method, etc.

Input/output settings: Configure analog input (such as 4-20mA), digital input (wet/dry contacts), and output relay (trip/alarm).

Protection settings: Threshold, delay, action mode (trip/alarm), etc. of each protection element, supporting multiple sets of setting point switching.

Specifications and Safety

Environmental parameters: Operating temperature -40 ° C to 60 ° C, humidity 0-95%, no condensation, seismic rating IEC 60255-21-3 Class 2.

Safety certification: CE, UL508, ISO 9001, etc., in compliance with EMC standards (EN 61000 series).

Warning: Before operation, the dangerous voltage must be disconnected, and the CT secondary side must not be open circuited. Suitable personal protective equipment must be used.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923