K-WANG

ABB NTAC-0x pulse encoder interface module

Attention: Emphasize following the manufacturer's operating instructions to avoid hazards such as electric shock.

ABB NTAC-0x pulse encoder interface module

Safety instructions

Warning types: including dangerous voltage warning, general warning, electrostatic discharge warning, reminding users to have professional electricians perform electrical installation and maintenance. Drivers and related equipment must be properly grounded. After power failure, wait for 5 minutes for the intermediate circuit capacitor to discharge, and use voltage indicating instruments to confirm the completion of discharge. At the same time, be aware of the risks that may arise from the automatic reset function of the driver.

Attention: Emphasize following the manufacturer's operating instructions to avoid hazards such as electric shock.

Overview

Scope of application: Applicable to NTAC-02 (revised version C and above), NDIO-02 (revised version A and above), NAIO-03 (revised version A and above), and includes reference information from earlier versions (NTAC-01, NDIO-01, NAIO-01/02).

Module function:

NTAC-02: Provides a digital pulse encoder interface for obtaining precise speed or position feedback of the motor shaft.

NDIO-02: Provides 2 digital inputs and 2 relay outputs.

NAIO-03: Provides 2 analog inputs and 2 analog outputs, with signal resolution (12 bits) superior to standard analog I/O.

Communication link: Connected to the frequency converter through an optical DDCS protocol communication link, the module and NIOC standard I/O board usually form a circular connection on the CH1 channel of the NAMC board, which acts as the main station to cyclically poll other stations.

install

Module Node Number Setting: Different modules (NTAC, NDIO, NAIO) have their own node numbering rules set through DIP switches inside the module casing. The new settings will take effect when the module is powered on next time.

Mechanical installation: It can be installed inside or outside the drive. When installing outside, attention should be paid to wiring, space, environmental conditions, and grounding requirements. When installing inside, it should be operated by a professional electrician, following steps such as power-off, discharging, and removing the cover plate.

ACS 600 connection: Use fiber optic cables to connect to the NAMC/NDCO board of the driver, paying attention to the color coding of the connectors (blue for RXD, gray/black for TXD). Multiple modules are connected in a circular manner on the same channel, and the terminals connected to different modules vary depending on the application.

Detailed installation and configuration of each module

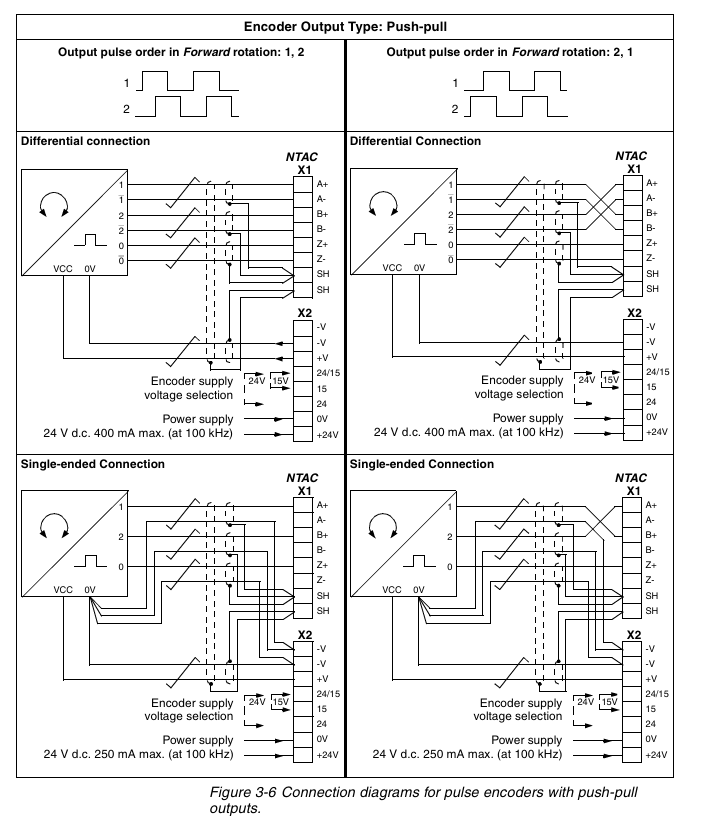

NTAC-02 pulse encoder interface module: introduces terminal identification, current consumption, wiring requirements (cable type, length, shielding grounding, etc.), encoder output type connection diagram (push-pull, collector open circuit, emitter open circuit), and programming method (set through driver parameters).

NDIO-02 digital I/O expansion module: including terminal identification, wiring recommendations, DI1 hardware filter suppression settings, and programming methods (activating communication through driver parameters).

NAIO-03 Analog I/O Expansion Module: Includes mode selection (unipolar/bipolar), input signal type selection (current/voltage), terminal identification, wiring requirements, programming methods (activates communication through driver parameters to ensure parameter settings correspond to module mode switches).

Appendix Information

Technical data: including detailed technical parameters such as I/O expansion links, enclosure of each module, installation, connectors, input and output.

Environmental conditions: lists the environmental requirements for temperature, humidity, vibration, impact, etc. of the module during operation, storage, and transportation.

Early version information: Introduces the differences, terminal identification, settings, and other information between NTAC-01, NDIO-01, NAIO-01/02 and their corresponding new versions.

Install and start ABB NTAC-0x module

Installation preparation

Confirm compatibility

The module needs to be used in conjunction with the ACS 600 series frequency converter, and the application version must be ≥ V5.0 (standard application) or ≥ V4.2 (system application).

Check the encoder type (push-pull, open collector or open emitter) and prepare matching connecting cables.

Safe power outage

Disconnect the main power supply of the frequency converter and wait for 5 minutes until the intermediate circuit capacitor discharges completely.

Use a voltage indicator to confirm that there is no residual voltage.

Physical installation steps

1. Node number setting

Open the module casing and set the node number (range: 1-31) through the DIP switch.

Rule:

The NTAC module number needs to be an even number (such as 2, 4, 6...).

Node numbers within the same channel cannot be duplicated.

After the setting is completed, it will take effect when powered on again.

2. Mechanical installation

Internal installation (recommended):

Remove the cover plate of the frequency converter and insert the module into the CH1 channel of the NAMC board or NDCO board.

Connect the RXD (blue interface) and TXD (gray/black interface) of the module using fiber optic cables to form a circular topology.

External installation:

Choose a dry and ventilated location to ensure that the ambient temperature is between -25 ° C and+55 ° C.

Fix the module with M4 screws and maintain a minimum spacing of 50mm.

3. Encoder connection

Select the corresponding terminal based on the encoder type (such as A+/A -, B+/B -).

Wiring requirements:

Use shielded cables with both ends of the shielding layer grounded.

The encoder cable should be kept at least 100mm away from the power cord to avoid interference.

Maximum cable length: push-pull encoder ≤ 100m, differential encoder ≤ 300m.

Electrical connection

1. Power connection

The module is powered internally by the frequency converter and does not require additional power supply.

2. Fiber optic communication connection

Connect the RXD (receiver) of the module to the TXD (transmitter) of the previous node to form a circular link.

The TXD of the last module needs to be connected back to the NAMC board or NDCO board of the frequency converter.

3. Encoder signal connection

Push pull encoder: directly connected to the digital input terminal of the module.

Differential encoder: Connected after conversion by a differential receiver.

Troubleshooting

communication failure

Check if the fiber optic connection is secure and if the interface is clean.

Confirm that there are no conflicts in the node numbers and that all module numbers are even.

Encoder signal loss

Check if the encoder power supply is normal (usually+5V or+24V).

Use an oscilloscope to check if the encoder output waveform is stable.

Parameter not effective

Restart the frequency converter and ensure that the parameters are saved to non-volatile memory.

Precautions

Static protection: Wear an anti-static wristband before operation to avoid touching the circuit board.

Environmental requirements: Avoid installation in damp, dusty, or strong electromagnetic interference environments.

Maintenance: Regularly clean the module's heat dissipation holes and check for dust or damage to the fiber optic interface.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB AX411/511010/STD pH/ORP Analyzer Controller

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923