K-WANG

Bently Nevada 3500 Monitoring System Rack Installation and Maintenance

Core advantage: Enhanced operator information (providing multi-dimensional data, Windows) ® Basic display software, better integration of factory control computers (multi protocol communication gateway, time synchronization data), reduced installation and maintenance costs (reduced wiring, backward compatibility, easy configuration), improved reliability (redundant power supply, TMR system), intrinsic safety options, multiple output interfaces (supporting multiple display and control systems).

Bently Nevada 3500 Monitoring System Rack Installation and Maintenance

Receiving and Processing Instructions

Receiving inspection

Visually inspect the system for any obvious transportation damage. If there is any damage, file a claim with the carrier and submit a copy to Bently Nevada, LLC.

Handling and storage precautions

The circuit board is susceptible to static damage and requires the use of a grounding strap (such as 3M Velostat) before operation ® No.2060) Grounding: Avoid using tools/materials that are prone to static electricity, such as ungrounded soldering irons and non-conductive plastics.

Transport and storage of circuit boards require the use of conductive bags or foil, and special attention should be paid to static electricity accumulation in dry weather (humidity<30%).

When the system loses power, it will lose its mechanical protection function; When operating correctly, the module can be plugged in and out while powered on (see Chapter 4 for details).

Basic Information

System Overview

The 3500 monitoring system is used to continuously monitor the status of rotating and reciprocating machinery (such as imbalance, misalignment, shaft cracks, bearing failures, etc.) to improve factory safety, product quality, equipment availability, and reduce operating costs.

Core advantage: Enhanced operator information (providing multi-dimensional data, Windows) ® Basic display software, better integration of factory control computers (multi protocol communication gateway, time synchronization data), reduced installation and maintenance costs (reduced wiring, backward compatibility, easy configuration), improved reliability (redundant power supply, TMR system), intrinsic safety options, multiple output interfaces (supporting multiple display and control systems).

General characteristics

Hot swappable module: When operated correctly, any module can be plugged in and out while the system is powered on, without affecting the operation of unrelated modules (plugging in and out of the power supply does not interrupt the system when dual power is available).

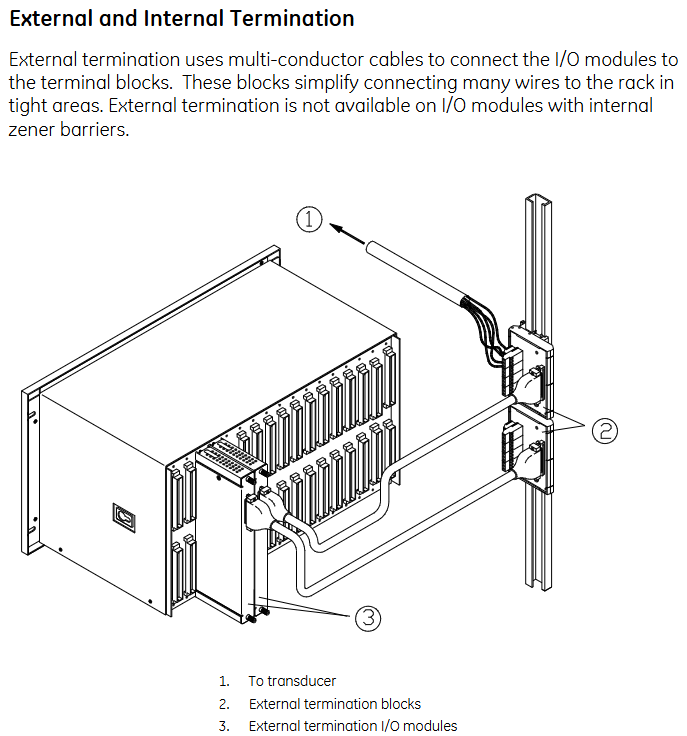

Internal and external terminals: External terminals are connected to I/O modules and terminal blocks through multi-core cables (suitable for narrow space areas); Internal terminals allow sensors to be directly connected to I/O modules (I/O modules with internal Zener barriers have no external terminals).

System components

Including a weatherproof enclosure (protecting the rack from moisture and dust), rack (full-size 19 inch/compact 12 inch Mini rack), power supply (half height module, supporting 1-2 redundant installations), Rack Interface Module (RIM, communicating with the host and other modules, maintaining event lists), communication gateway module (allowing external devices to access information), monitoring module (collecting sensor data), relay module (controlling relays based on channel status) Keyphasor ® Modules (supplying power to sensors and processing signals), display modules (supporting multiple display devices), grounding modules (providing low impedance grounding, used in conjunction with internal barrier I/O modules), etc.

Relays and Safety Systems

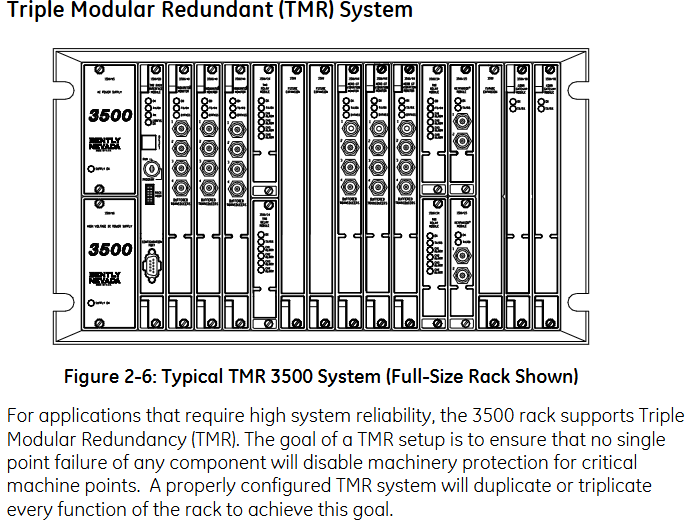

Standard rack relay options: independent relay (each monitoring module is equipped with more than one relay module), bus relay (multiple monitoring channels share a single relay), Triple Modular Redundancy (TMR) system (high reliability configuration, triple redundancy function, avoiding single point failure).

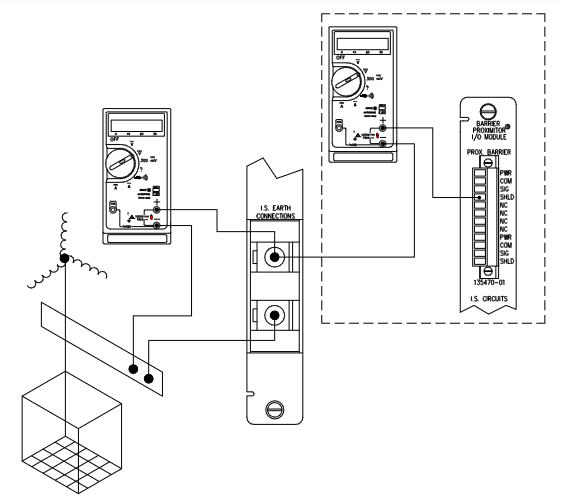

Intrinsic safety internal barrier system: suitable for hazardous environments, needs to be used in conjunction with grounding modules, has strict installation restrictions (such as prohibiting the use of bus sensors, requiring isolation of RS-232 connections, etc.), and has characteristics such as dual IS grounding and safe/hazardous area wiring separation.

Initial rack installation

General installation process

Refer to the installation checklist (confirm conditions such as power supply, space, ventilation, grounding, etc.);

Install weatherproof casing (if required);

Install the rack;

Set rack jumpers and switches;

Install external terminal blocks (if necessary);

Install modules;

Connect sensors, relays, and power wiring;

Complete the software configuration for rack installation.

Key installation details

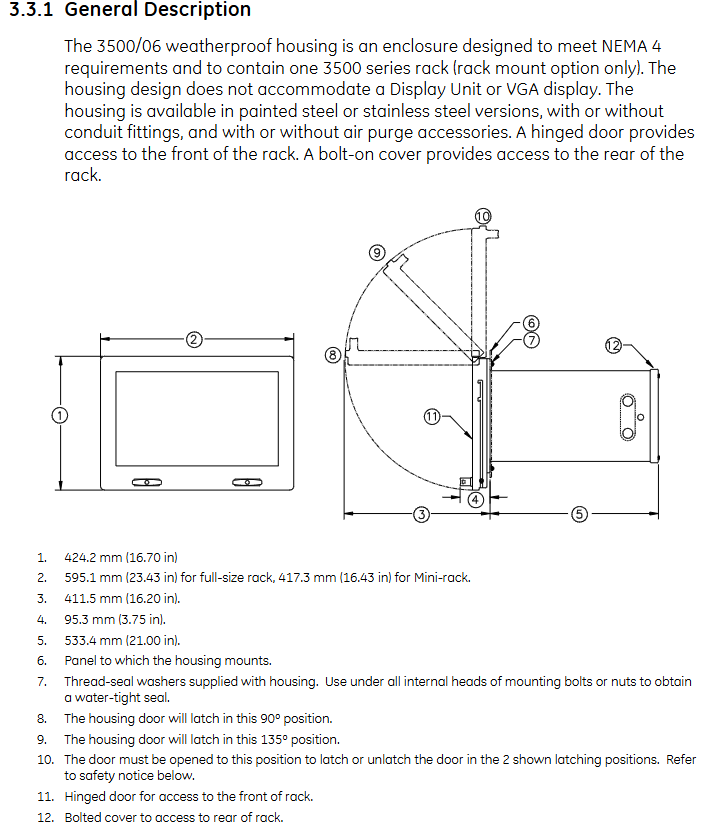

Weather resistant enclosure: Meets NEMA 4 requirements, not compatible with display units; Attention should be paid to temperature derating (due to limited ventilation), panel cut size, conduit fittings (to avoid mixing power and signal wiring), and air purification options (to meet specific pressure and flow requirements).

Rack installation: Ensure ventilation (minimum gap of 50.4mm between top and bottom), support panel installation, rack installation (19 inch EIA cabinet), Bulkhead installation, etc. Different installation types have specific size and fixing requirements.

Intrinsic safety operation: Ensure that the grounding resistance is less than 1 Ω, use 4-10mm ² cables to connect to the factory's IS grounding, and use a single point grounding to avoid loops.

High electromagnetic noise/CE installation: The system rack, EMI shielding, and cables must be thoroughly grounded to shield all wiring out of the metal cabinet. CE installation must comply with EN61000.3.2 standard.

Module installation and removal

Installation steps

Power supply: First install the Power Input Module (PIM), configure single point grounding, connect the power cord (in a non powered state), then install the main module and tighten the screws.

Full height module: First install the I/O module (configuration options, fastening screws, connection wiring), and then install the main module (ensure that the ejectors are in place, inserted along the guide rail, and fastened).

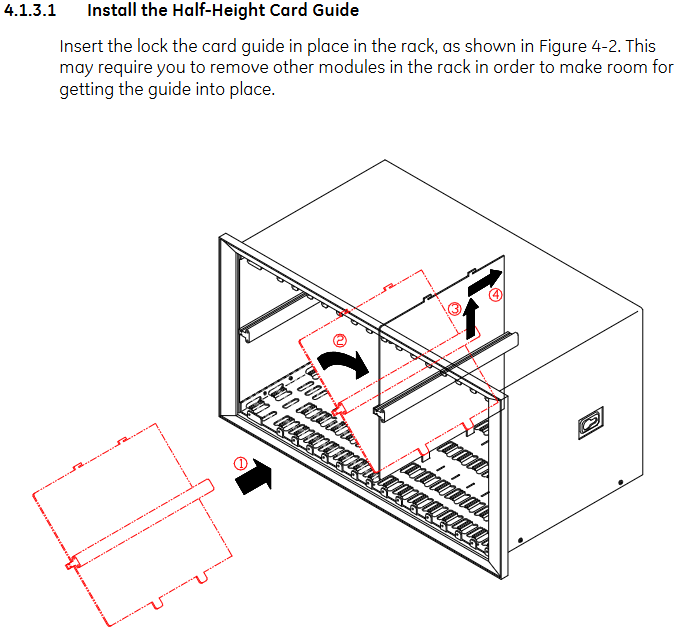

Half height module: First install the half height card guide rail, then install the I/O module and main module, similar to the steps for full height modules.

Remove steps

After power off, loosen the module screws and use ejectors (full height) or screws as handles (half height/power) to pull out the module; The I/O module needs to remove the wiring first, and then loosen the screws to remove it.

Replace module

Main module: Save the configuration before removing the old module, reconfigure and verify after installing the new module.

I/O module: The main module and wiring need to be removed first, replaced, reconnected, and verified.

Maintenance

General maintenance

The internal components of the module cannot be repaired on site, and maintenance mainly involves testing whether the channel is normal and replacing faulty modules (spare parts are required).

Support live plugging and unplugging modules (follow the steps in Chapter 4), the system does not require calibration, but the functionality needs to be verified regularly.

Maintenance interval

The initial interval is 1 year; If the monitoring machine is a critical equipment or the rack is in an extreme temperature, high humidity, or corrosive environment, the interval needs to be shortened; Adjust the interval based on the verification results and ISO 10012-1 after each maintenance.

Order Information

Rack ordering: Specify the size (19 inches/12 inches Mini rack), installation method (panel/rack/Bulkhead installation), institutional certification (CSA-NRTL/C), European compliance (CE), etc. through code.

Windproof shell ordering: optional materials (painted steel/stainless steel), conduit fittings, air purification options, etc., incompatible with display units, Mini rack requires adapter panel.

Grounding module and spare parts: The grounding module needs to occupy one rack slot; Spare parts include TMR/SIM jumpers, blank panels, adapters, etc.

Specification parameters

Dimensions: Detailed length, width, and height data for different installation types (panel/rack/Bulkhead installation, full-size/Mini rack) (such as full-size panel installation rack width 482.6mm, height 265.9mm).

Weight: The weight of different configurations (empty/full load, with internal barriers) (such as a full-size full load panel installation of approximately 31.07kg).

Environmental parameters:

Working temperature: -30 ° C to 65 ° C (0 ° C to 65 ° C with internal barrier); Storage temperature: -40 ° C to 85 ° C.

Humidity: 0% -95% without condensation.

Mechanical performance: 10g impact (11ms); 3g sine vibration (5-100Hz).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923