K-WANG

ABB PFEA113 Tension Electronic Equipment

ABB PFEA113 Tension Electronic Equipment

Product positioning

PFEA113 is based on Presductor ® The high-precision tension measurement and control system of technology is used for tension detection and control in the production process of coil materials such as paper, metal strips, and plastic films. It supports multiple types of weighing sensors (PFCL 301E, PFTL 301E, etc.) and is widely used in industries such as papermaking, printing, and metallurgy.

System composition and core technology

1. System composition

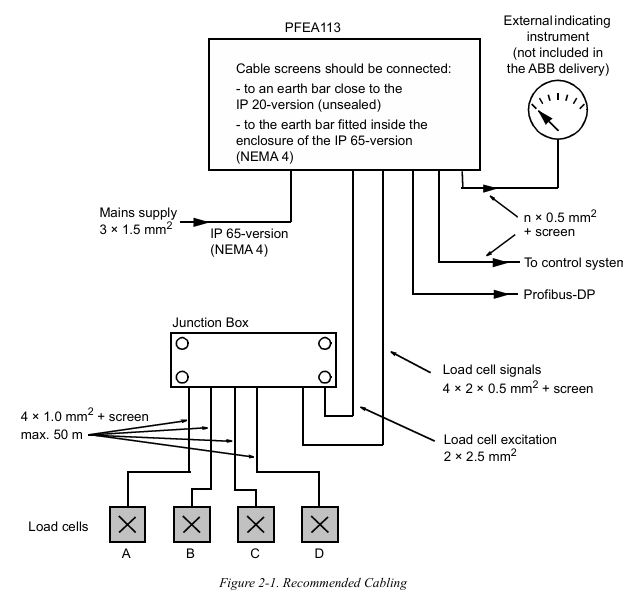

Core components: Tension electronic unit (PFEA113), weighing sensors (such as PFCL/PFTL series), junction box (PFXC 141), power module, and communication interface.

Measurement principle: Based on the magnetostriction effect, the sensor core is a stacked alloy sheet. A 330Hz AC current is passed through the primary winding to generate a magnetic field. The secondary winding induces a voltage signal proportional to the tension due to mechanical force, and has strong resistance to lateral and axial force interference (error ≤± 0.5%).

2. Core Features

Multi scenario adaptation: Supports single roll, double roll, and segmented roll applications, and can connect up to 12 sensors (cascaded through 3 PFEA113).

Flexible expansion: 6 configurable analog outputs, 4 digital outputs, supports Profibus DP communication, compatible with remote control and data upload.

High reliability: It has protection functions such as overvoltage (OVP), overcurrent (OCP), and over temperature (OTP), and supports fault self diagnosis.

Installation and wiring specifications

1. Installation environment requirements

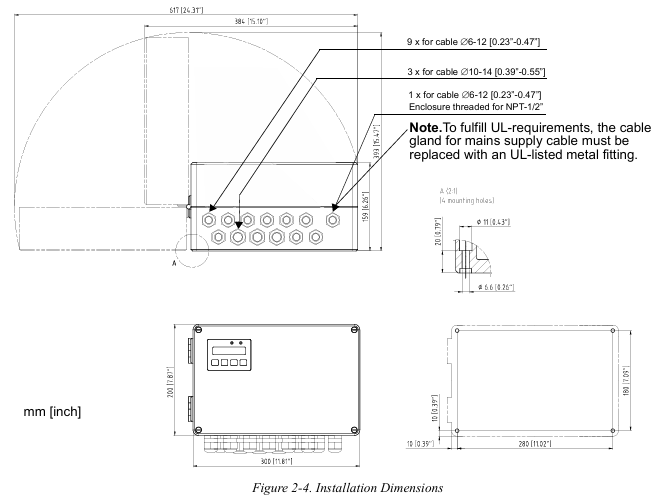

Physical environment: Operating temperature -10~+55 ℃ (IP20 version), -25~+70 ℃ (IP65 version), relative humidity ≤ 95% (no condensation), avoid strong electromagnetic interference sources (such as frequency converters).

Mechanical requirements: The flatness error of the installation surface should be ≤ 0.1mm, and the gap between the sensor and the adapter plate should be clean and free of debris to avoid force diversion affecting measurement accuracy.

2. Hardware wiring

Sensor wiring:

Analog input supports CT (1A/5A), VT (100V), and sensor signals, and the cable needs to be twisted shielded with a single end grounding of the shielding layer.

Switching input/output adopts optocoupler isolation, with digital output capacity 5A@250V AC/DC, Inductive loads require parallel freewheeling diodes.

Power and Communication:

Wide range auxiliary power supply (24-250V AC/DC, IP20 version) or 85-264V AC (IP65 version), power consumption<15W.

The communication interface supports Profibus DP (RS485) and RS232, with a standard 120 Ω terminal resistor and a maximum communication distance of 1200m.

Debugging and configuration process

1. Basic settings

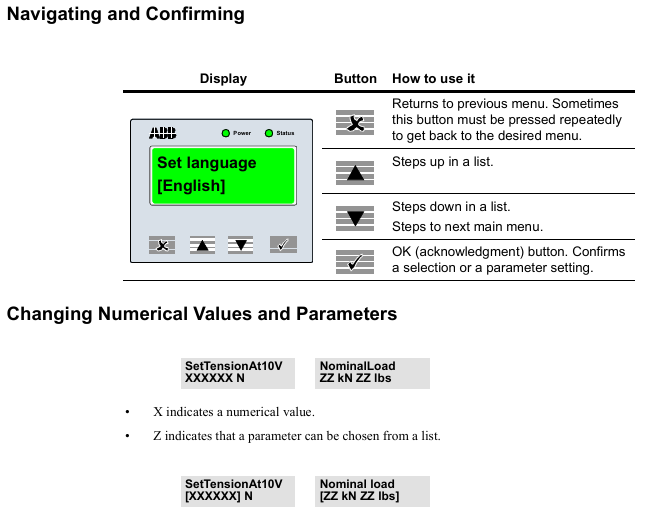

Quick configuration: Set language (English/German/French, etc.), unit (N/kN/kg, etc.), and web width (applicable to N/m, etc.) through panel buttons, supporting fast zero calibration and gain scheduling.

Complete configuration: including system definition (single roll/double roll/segmented roll), sensor type selection, nominal load setting, zero calibration, and wrrap gain calculation (calculated by hanging weight or formula).

2. Key parameter configuration

Wrap gain: the ratio of tension (T) to sensor measured force (FR), calculated as Wrap gain=T/FR, which needs to be derived through geometric relationships based on the installation angle (horizontal/inclined).

Communication settings: Profibus DP address (0-125), baud rate (up to 12Mbps), supports real-time data exchange with PLC or SCADA systems.

Operation and maintenance

Daily operating procedures

1. Startup and shutdown

(1) Startup steps

Pre inspection

Confirm that the main power supply voltage matches the rated value of the equipment (IP20 version: 24V DC; IP65 version: 85-264V AC).

Check that the sensors, junction boxes, and communication cables are securely connected without looseness or damage.

Power on operation

Turn on the external power switch, and the IP65 version requires the internal switch of the device to be turned on at the same time.

The "Power" indicator light (green) on the observation panel is on, and the "Status" indicator light (green) is constantly on, indicating that the system is normal; If the "Status" light is red, the fault information needs to be viewed through the display screen.

(2) Shutdown steps

Turn off the external power switch. For IP65 version, the internal switch of the device needs to be turned off first.

When the machine is shut down for a long time, it is recommended to disconnect the main power supply and protect the equipment from dust.

2. Operation monitoring

(1) Panel operation

Display switching: Use the "Step up/down" button to switch display content, including single sensor tension (such as Tension A), total tension (such as TensionRoll 1), differential tension (such as TensionDiff A-B), and analog output values (AO1-AO6).

Parameter viewing: Press and hold the "OK" button for 5 seconds to enter the menu, where you can browse the system status, fault records, and configuration parameters (such as w_rap gain _, nominal load).

(2) Remote monitoring

Through Profibus DP communication, the upper computer (such as PLC) can read tension values, sensor status, and alarm information in real time, and support remote sending of zero calibration, gain switching, and other instructions.

3. Key operational functions

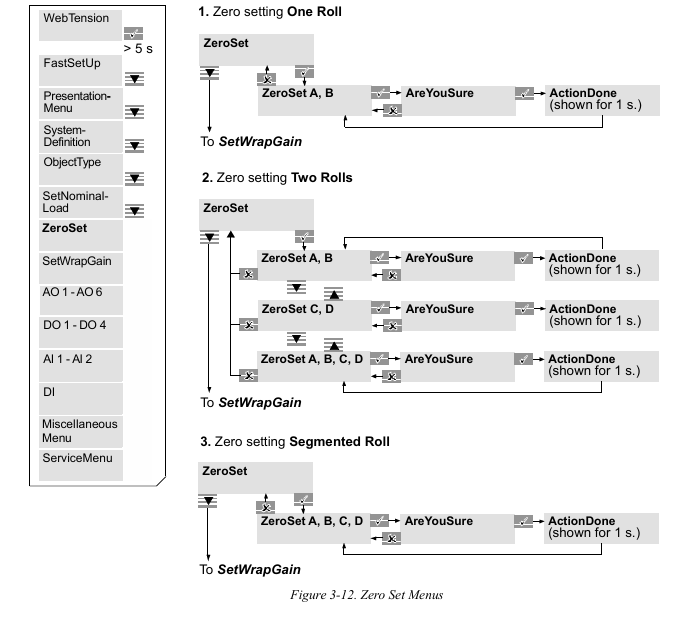

(1) Zero point calibration

Trigger condition: When no tension is applied (such as when the coil is not running), execute it through the "Zero Set" menu on the panel or remote command.

Operation steps:

Enter the "ZeroSet" menu and select the corresponding sensor group (such as A, B).

After confirming that there is no tension, press "OK" and the display screen will show "ActionDone" to indicate completion.

(2) Gain scheduling

Application scenario: Suitable for changes in coil path (such as different wrrap angles), switching preset wrrap gain parameters through digital input or Profibus.

Setting method: Enable "GainScheduling" in the "SystemDefinition" menu, and configure the w_rap gain 1_ and w_rap gain 2h respectively.

Maintenance and upkeep

1. Preventive maintenance

(1) Regular check (recommended every 6 months)

Key operating points for inspection items

Check the torque of the fixing screws for sensors and connectors (e.g. 24Nm for M12 screws), and clean the dust or debris in the gap between the sensor and adapter board.

Confirm that the cable and shielding layer are not worn, and that the shielding layer is grounded at one end (distance ≤ 50mm) to avoid interference caused by grounding at both ends.

Ventilation openings for heat dissipation and environmental cleaning equipment ensure that the working environment temperature and humidity are within the rated range (without condensation or corrosive gases).

(2) Calibration and verification

Calibration cycle: It is recommended to perform accuracy calibration once a year, using standard weight or calibration equipment to verify measurement errors (should be ≤ ± 0.5% FS).

Verification method: Enter a known tension value through the simulation function in "DataMenu", and compare the displayed value with the theoretical value.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923