K-WANG

WOODWARD Peak200 Steam Turbine Controls

WOODWARD Peak200 Steam Turbine Controls

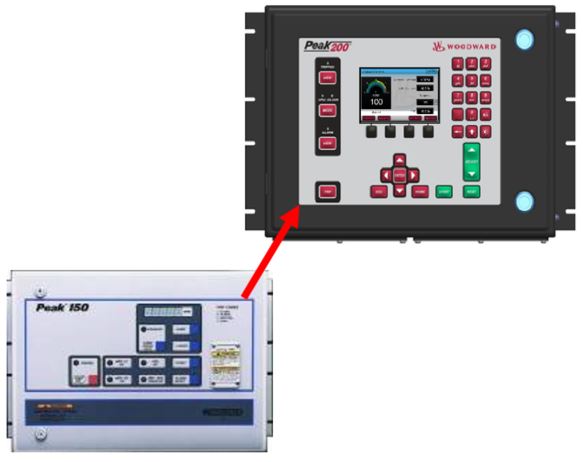

Product Overview

The Peak200 series controllers come in multiple models to meet different operating conditions and installation requirements. From the perspective of installation methods, there are two options: Bulkhead Mount and Front Panel Mount. In terms of voltage adaptation, it covers low voltage (LV, such as 24 VDC) and high voltage (HV, such as 120/220 VAC) models. In addition, there are corresponding certified models for hazardous areas such as ATEX Zone 2, Class1 Div2 Haz. Loc. Compliant, etc., to ensure safe and stable operation in special environments.

Product advantages

High control accuracy: Supports proportional, integral, and derivative (PID) control algorithms, enabling precise control of key parameters such as speed and load. In terms of speed control, the control error can be as low as ± 0.5% to ensure that the steam turbine always operates in the optimal state; In terms of load response, the response time is less than 500ms, which can quickly adapt to changes in load and ensure the stability and reliability of the system.

Easy to operate: It is a configurable controller on site, with a built-in graphical user interface (GUI) that adopts a menu driven screen design. Site engineers do not need to have complex programming skills to easily configure controls for specific application settings. This convenient operation method not only improves configuration efficiency, but also reduces the requirement for professional skills of operators, making equipment installation, debugging, and daily maintenance easier and more feasible.

Strong environmental adaptability: Some models have undergone sulfur resistant conformal coating treatment, giving them excellent corrosion resistance and the ability to operate stably in harsh environments containing corrosive substances such as sulfur. The working temperature range of ordinary position models is -20 ℃ -+60 ℃, while the certified models for hazardous areas strictly follow relevant standards to ensure safe operation in hazardous environments. The product has a wide range of applications and can meet the steam turbine control needs of different industries and environments.

High cost-effectiveness: Its single design can be widely applied to various control application scenarios, and enterprises do not need to purchase multiple complex controllers for different projects or needs, greatly reducing procurement and customization costs. At the same time, the product has a short delivery time, which can quickly meet the urgent needs of the project, reduce the overall project cycle, improve the production efficiency of the enterprise, and bring higher economic benefits to the enterprise.

Good continuity of functional upgrades: Based on the mature 505 platform, a new design has been carried out, inheriting some mature technologies and basic functions of the 505 platform, such as speed control PID, startup mode (manual, automatic), critical speed band, remote speed set point (configurable), overspeed protection and testing capabilities, acceptance of redundant speed sensors, user configurable, etc., ensuring the stability and reliability of the product; On this basis, functional upgrades have been made, adding new features such as graphical HMI, front panel configurability (without the need for handheld devices), multilingual capability, first trip event latch, trip and alarm logs, real-time trends, internal turbine simulator, and one process control PID (cascaded PID), providing users with a richer, more convenient, and efficient user experience.

Model and configuration specifications

Installation method

Bulkhead Mount: Suitable for internal integration of equipment, saving space

Front Panel Mount: convenient for on-site operation and visual monitoring

Voltage level

Low voltage (LV): 24 VDC (typical models: 8200-1500, 8200-1503)

High Voltage (HV): 120 VAC/DC, 220 VAC (Typical Models: 8200-1501, 8200-1504)

Hazardous Area Certification

ATEX Zone 2: Suitable for explosive gas environments (such as 8200-1502, 8200-1505)

Class1 Div2 Haz. Loc. Compliant: North American Hazardous Area Certification (e.g. 8200-1508, 8200-1509)

Example of Core Component Number

Installation of cabin wall LV: 8200-1500

Front panel installation HV: 8200-1504

- ATEX Zone 2:8200-1502

- Class1 Div2:8200-1508

Technical specifications and specifications

Control accuracy

Speed control: ± 0.5% rated speed (NEMA D-class standard)

Load distribution error: ≤ 1% (when multiple machines are connected in parallel)

Input power supply

LV model: 24 VDC (± 10%)

HV model: 120 VAC/DC (± 15%) or 220 VAC (± 10%)

Hazardous area model: equipped with explosion-proof power isolation design

Signal input/output

Analog input: 4-20mA (remote speed setting), 0-5V

Analog output: 4-20mA (load control)

Digital input/output: dry contact (start/stop signal, alarm output)

communication interface

-2 x Ethernet (10/100Mbps, supports Modbus TCP)

-2 x CANopen (supports DS301/DS401 protocol)

- 1×RS485(Modbus RTU)

Display interface

Graphic HMI: 128 × 64 pixel menu driven screen, supporting multiple languages (Chinese, English, Spanish, etc.)

-Real time display: parameters such as speed, load, temperature, fault codes, etc

Functional performance specifications

Speed Control

Dual dynamic PID algorithm, response time<200ms

-Speed range: 0-150% rated speed (configurable)

-Critical speed avoidance: automatically skipping the resonance speed range

load control

Support constant speed, constant power, and constant pressure control modes

-Load step response time < 500ms (10% → 90% load change)

Start and Stop

Manual start: step-by-step control (warm-up, acceleration, grid connection)

-Auto start: One click completion of the start sequence (including sequential control logic)

-Emergency stop: response time<100ms

Safety protection

Overspeed trip threshold: 110% -115% rated speed (adjustable)

-Bearing temperature protection: ≥ 120 ℃ (configurable)

-Vibration protection: ≥ 50 μ m (peak to peak, configurable)

data record

Trip log: stores the last 50 event records

-Trend curve: Supports real-time trend of 8 parameters (storage time ≥ 72 hours)

Environmental adaptability specifications

operation temperature

Normal model: -20 ℃~+60 ℃

-Hazardous area model: -40 ℃~+70 ℃ (ATEX certification scope)

protection grade

Front panel installation: IP54 (splash proof)

Cabin Wall Installation: IP20 (Indoor Environment)

Corrosion Resistance

Optional sulfur resistant conformal coating (suitable for corrosive gas environments containing H ₂ S, etc.)

Anti vibration

-5-50Hz, 2G (compliant with ISO 16750-3 standard)

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- xYCOM

- Construction site

- Siemens

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Motorola

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive