K-WANG

XYCOM Pro-Face 3712 KPM Industrial PCs

Complex operations and screens can be displayed with clarity.

SVGA (800 x 600) resolution is recom mended.

However, the 3712KPM units will display XGA (1024 x 768) resolution with some clarity degradation. The AGP graphics defaults to 4MB video RAM and will automati cally share RAM (up to 32 MB) with the system to allow full 32-bit color depth.

XYCOM Pro-Face 3712 KPM Industrial PCs

The 3712KPM units utilize a bright TFT 12.1"LCD flat panel display.

Complex operations and screens can be displayed with clarity.

SVGA (800 x 600) resolution is recom mended.

However, the 3712KPM units will display XGA (1024 x 768) resolution with some clarity degradation. The AGP graphics defaults to 4MB video RAM and will automati cally share RAM (up to 32 MB) with the system to allow full 32-bit color depth.

Higher Performance

With up to 1.26 GHz Pentium ® III processors available, the 3712KPM units can drive the most demanding applications.

The 3712KPM units ship standard with a Pentium III 1 GHz with 256K cache running at 133 MHz bus. A 1.26 GHz Pentium ® III with 512K cache running at 133 MHz bus is an available option

Cutout Compatibility

The 3712KPM is directly cutout-compatible with many Xycom Automation legacy units.

It offers a hardware upgrade path for many units, including the 2050, 8450, 9450, 9475,

9485, 9486, 9486 and the 9487 without the need to alter your current enclosure and/or

machine.

For a more complete list, or to verify compatibility, contact Xycom Customer

Care.

Fits Your Needs

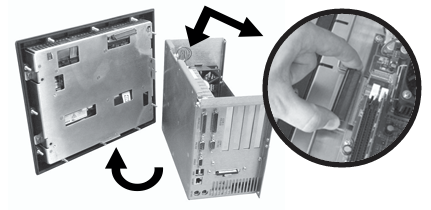

The 3712KPM can be configured many different ways.

With four available expan sion slots (three full-length ISA/PCI, one ½ length PCI), many cost-effective, industry standard options are easily integrated.

The optional dual hard drive, solid-state drive,externally accessible CompactFlash ™, or

External Drive bay connector provide the storage solution you require.

Additionally, the CD-ROM can be upgraded to CD-R/W, DVD,or DVD-R/W, so that even more storage and/or backup options are available.

The optional 9000-XBAY allows you to externally mount any two IDE devices without requiring a

power supply or unreliable cabling.

Meets High Standards

To survive on the plant floor, the 3712KPM units meet NEMA 4/4x/12, IP65, FCC, UL,

CSA, and European CE mark requirements for industrial automation equipment. Xycom

Automation leads the industry in reliability,service, and support with an optional five

year warranty available.

Product Overview

The Xycom 3712KPM industrial computer is a high-performance computing device designed specifically for harsh industrial environments. With its robust and durable design, powerful computing capabilities, and excellent compatibility, it plays a key role in automation production lines, smart factories, energy monitoring, and other fields, providing stable and reliable hardware support and data processing platforms for industrial control systems.

Specification parameters

(1) Hardware configuration

Processor: Equipped with a high-performance industrial grade processor (specific model depends on version), it has powerful data processing and multitasking capabilities, can quickly respond to industrial control instructions, and ensure efficient system operation.

Memory: Supports large capacity memory expansion to meet the needs of complex industrial applications for data storage and fast read and write, ensuring smooth running of multiple programs simultaneously.

Storage: Equipped with high-speed solid state drives (SSDs), it has the characteristics of fast data read and write speed, strong shock resistance, and low energy consumption. At the same time, it supports multiple storage interfaces for convenient data storage and backup.

(2) Electrical parameters

Working voltage: Supports wide voltage input, can adapt to AC voltage range of 100-240V, frequency of 50/60Hz, effectively resists voltage fluctuations, and ensures stable operation in different power environments.

Power consumption: Optimized power management design reduces device operating power consumption, reduces energy consumption and heat dissipation burden, and improves overall operational efficiency.

(3) Physical specifications

Size and weight: Compact and sturdy design, reasonable size for easy installation in limited spaces such as industrial control cabinets and workstations, moderate weight, and balance portability and stability.

Protection level: It has a high protection level (such as IP65), is dustproof and waterproof, and can effectively resist the erosion of dust, oil, and water vapor in industrial environments, adapting to harsh production environments.

Heat dissipation design: adopting efficient heat dissipation structure, such as large-area heat dissipation fins combined with intelligent fan speed control system, to ensure that core components such as processors maintain reasonable working temperature under long-term high load operation and improve equipment reliability.

Core functions

(1) Industrial grade stability

After rigorous industrial testing and certification, it can operate stably in extreme temperature environments ranging from -40 ℃ to 85 ℃, and has excellent anti vibration and anti impact performance, effectively responding to frequent mechanical vibrations and transportation bumps in industrial sites.

Supports 24/7 uninterrupted operation, with hardware watchdog function that automatically restarts in case of system abnormalities, ensuring continuous and stable operation of industrial control systems, reducing downtime and production losses.

(2) Powerful communication and expansion capabilities

Rich interfaces: equipped with multiple standard communication interfaces, including Ethernet interface (supporting high-speed network communication, realizing fast data transmission and remote monitoring between devices), serial port (RS232/RS485, adapted to traditional industrial equipment communication), USB interface (convenient for connecting external storage devices, printers, etc.), CAN bus interface (suitable for industrial fieldbus communication, realizing real-time data exchange between devices), etc., to meet the connection needs of different industrial equipment.

Expansion slot: Provides PCI, PCIe and other expansion slots, which can flexibly expand functional modules according to actual application needs, such as adding data acquisition cards to achieve multi-channel analog/digital acquisition, or inserting video acquisition cards to achieve industrial field video monitoring functions.

(3) Intelligent management and control

Support remote management function, which enables remote device monitoring, configuration, upgrading, and fault diagnosis through the network, facilitating technical personnel to maintain and manage devices in different locations, reducing operation and maintenance costs and time costs.

Built in industrial grade real-time operating systems (such as Windows Embedded, Linux Industrial, etc.), with features such as fast startup, high real-time performance, and strong stability, can accurately control and process real-time data in industrial production processes.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- xYCOM

- Construction site

- Siemens

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Motorola

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive