K-WANG

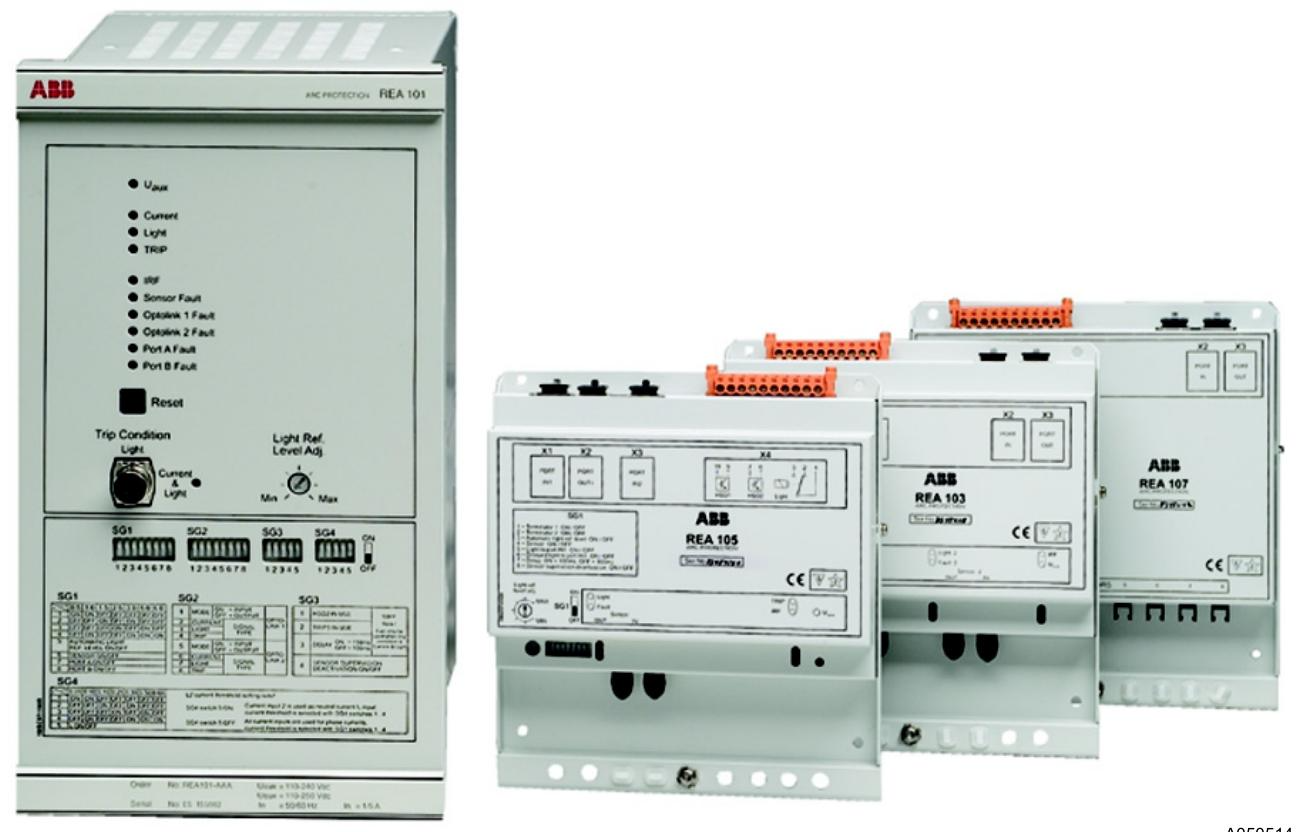

ABB REA 101 arc protection relay

ABB REA 101 arc protection relay

Product Overview

REA 101 is an arc protection relay (central unit) launched by ABB, which is the core component of REA 10_ arc protection system. It is mainly used in low-voltage or medium voltage air insulated metal enclosed switchgear, and can quickly send tripping commands to all circuit breakers that may supply power to arc faults, in order to minimize the damage caused by arc faults.

Brand background

REA 101 is produced by ABB company. ABB is a leading global enterprise in electrical and automation technology, with business covering multiple fields such as power, industry, transportation, and infrastructure. It has over 130 years of technological accumulation and innovative experience. Its products are renowned for their high quality, performance, and reliability, and have a wide influence in the field of industrial automation control. REA 101 is a reflection of its technical strength in the field of arc protection.

Specification parameters

Current input rated current 1A/5A; Continuous load current 4A/20A; Instantaneous current of 100A/500A per second; Dynamic withstand current (half wave value) 250A/1250A; Input impedance<100m Ω/<20m Ω; rated frequency 50/60Hz

Output HSO1 and HSO2: rated voltage of 250V DC/AC, continuous carrying of 1.5A, on-off of 30A in 0.5 seconds, on-off of 15A in 3 seconds, DC breaking capacity (when L/R<40ms) of 5A/3A/1A at 48V/110V/220V, respectively

TRIP3: Rated voltage 250V DC/AC, continuous load capacity 5A, on-off 30A in 0.5 seconds, on-off 15A in 3 seconds, DC breaking capacity (when L/R<40ms) 5A/3A at 48V/110V/220V respectively

IRF signal contact: rated voltage 250V DC/AC, continuous load 5A, on-off 10A in 0.5 seconds, on-off 8A in 3 seconds, DC breaking capacity (when L/R<40ms) 1A/0.25A/0.15A at 48V/110V/220V respectively

Control input (reset) rated voltage: 24/48/60/110/220/250V DC, 110/120/220/240V AC; Scope of work: 18-300V DC, 18-265V AC; Control current of 1.5-20mA; minimum pulse length of 1s

The optional action delay for circuit breaker failure protection is 100ms/150ms; The accuracy of HSO2 action time is ± 5% of the set value; TRIP3 is ± 5% of the set value+5-15ms

Rated voltage of power supply: 110/120/220/240V AC, 110/125/220/250V DC; REA101-CAA and REA101-CAAG are 24/48/60V DC

Voltage variation range: AC is 85-110% Ur, DC is 80-120% Ur

Power consumption is about 9W/12W in static/working state; The maximum output power of the port is about 19W; the maximum power consumption when connecting 10 expansion units is less than 50W

The maximum length of the sensor fiber is 60m when there is no connector or 1 connector; 50m when there are 2 connectors; 40m when there are 3 connectors; the working temperature range is -35-+80 ° C; the minimum bending radius is 50mm

The maximum total length of the connecting chain between the central unit and the expansion unit of the connecting cable is 40m

Optolink communication plastic fiber maximum length 40m; glass fiber maximum length 2000m

Set the current range with step sizes of 0.5, 1.0, 1.5, 2.5, 3.0, 5.0, and 6.0 times the rated current; Neutral line current setting step size 0.05, 0.10, 0.15, 0.25, 0.3, 0.5, 0.6 times rated current; Action accuracy is ± 5% of the set value or ± 2% of the rated current

Total action time HSO1 and HSO2<2.5ms; TRIP3<15ms

Environmental testing operating temperature range -10-+55 ° C; transportation and storage temperature range -40-+70 ° C; meets multiple environmental testing standards

The protection level of the shell is IP20; Weight approximately 4.6kg

Insulation test dielectric test 2kV, 50Hz, 1min; Impulse voltage test 5kV, 1.2/50 µ s, 0.5J; Insulation resistance>100M Ω (500V DC)

Electromagnetic compatibility meets multiple EMC testing standards, such as 1MHz pulse interference, electrostatic discharge, radio frequency electromagnetic field interference, etc

Core functions

Overcurrent detection: It can perform three-phase or two-phase neutral line overcurrent detection, with adjustable current threshold, and can quickly respond to fault currents.

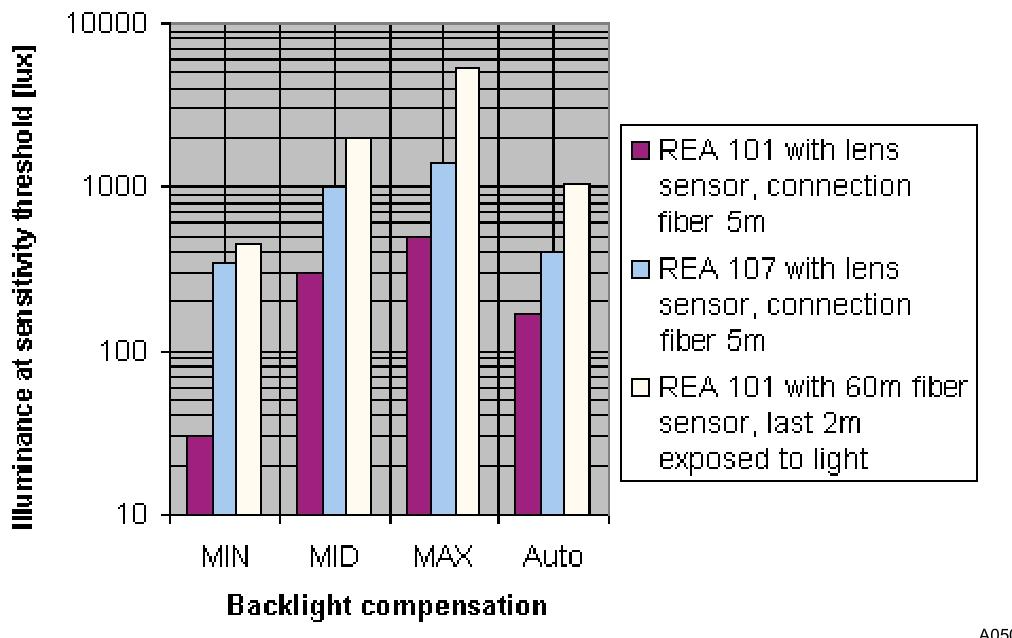

Arc light detection: Detect arc light through fiber optic sensors or lens sensors, activate when the light signal exceeds the set reference level, and support automatic or manual backlight compensation.

Trip output: Equipped with two high-speed solid-state (IGBT) outputs (HSO1, HSO2) and one overload relay output (TRIP3), used for circuit breaker tripping. The tripping condition can be set to meet both the optical signal and overcurrent signal or only the optical signal.

Expansion unit connection: Connect expansion units (such as REA103, REA105, REA107) through ports A and B. Each port can cascade up to 5 expansion units to expand protection range and selectivity.

Optolink communication: Two Optolink communication links can transmit optical signals, overcurrent signals, trip signals, etc. between central units to achieve collaborative protection.

Circuit breaker failure protection: When the circuit breaker fails to successfully disconnect the fault current, a trip command is issued to the upstream circuit breaker after a set delay.

Self monitoring: Continuously monitor the sensor fiber optic circuit, operating voltage, wiring between the central unit and expansion unit, etc. When a fault occurs, activate the corresponding indicator light and reset the IRF relay.

Working principle

REA 101 monitors fault current through overcurrent detection unit, and detects the light signal generated by arc light through arc light detection unit. When both overcurrent signal and optical signal are received simultaneously (and there is no working voltage fault signal), the tripping output is triggered, causing the circuit breaker to operate and cut off the fault circuit. Through Optolink communication, information exchange between central units can be achieved, and combined with extension units, the protection range can be expanded and selective tripping can be achieved. The self-monitoring unit monitors the equipment status in real-time to ensure the reliable operation of the system.

Key advantages

Quick response: The total action time is short (HSO1 and HSO2<2.5ms, TRIP3<15ms), which can quickly cut off faults, reduce equipment damage and personnel injury risks.

High reliability: equipped with comprehensive self-monitoring function, timely detection and indication of faults; Adapt to complex industrial environments through multiple rigorous insulation and electromagnetic compatibility tests.

Strong flexibility: Supports multiple sensors (fiber optic sensors, lens sensors), can operate independently or work in conjunction with other central units and expansion units to adapt to different protection needs.

Easy to expand: By connecting expansion units through ports, the protection range can be flexibly expanded according to the system size, improving system selectivity.

Accurate protection: dual detection of overcurrent and arc light to avoid misoperation and ensure reliable operation in the event of actual arc light failure.

Precautions

Safe operation: comply with national and local electrical safety regulations, only qualified electricians are allowed to carry out electrical installations; The equipment framework needs to be reliably grounded; The sensor fiber should be handled carefully to avoid sharp bends (minimum bending radius 50mm), and should not be placed on the ground during installation to prevent stepping on it; When changing settings and configurations, the auxiliary power supply needs to be disconnected.

Installation settings: The sensor fiber end needs to be protected to avoid unnecessary triggering; When connecting expansion units, pay attention to the port switch settings, and the last expansion unit needs to be connected to a terminal resistor; Settings and configuration changes need to be made with the auxiliary power disconnected.

Maintenance testing: Regularly check the current measurement function, optical signal transmission, etc; Follow the prescribed steps when testing the arc protection system to ensure its normal operation.

Environmental requirements: Use within the specified range of temperature, humidity, and other environmental parameters to avoid extreme environmental conditions affecting equipment performance.

Similar model supplement

REA103: Expansion unit that can add an arc light sensor circuit to expand the protection area and assist REA101 in achieving more comprehensive arc light monitoring.

REA105: Expansion unit with trip output, capable of selective tripping. When the arc fault is located behind a specific circuit breaker, it accurately controls the corresponding circuit breaker action, enhancing system selectivity.

REA107: Expansion unit with 8 lens sensor inputs, suitable for arc light monitoring of specific compartments, improving monitoring specificity.

Application scenarios

Mainly used for arc protection of low or medium voltage air insulated metal enclosed switchgear, such as power distribution systems in substations and industrial plants. A circuit breaker compartment that can protect busbars, outgoing feeders, cable terminals, etc. By cooperating with expansion units, it achieves comprehensive, fast, and reliable arc fault protection for complex distribution systems, suitable for electrical safety protection in fields such as power and industry.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923