K-WANG

ALSTOM RPH3/PS125b Controlled Switching Device,CT1VT220/TCR

Copyright belongs to GE Grid Solutions. The content is informative and can be adjusted according to technical and commercial needs. Unauthorized reproduction and disclosure are prohibited.

Alstom RPH3/PS125b Controlled Switching Device,CT1VT220/TCR

Document Overview and Core Positioning

Document property

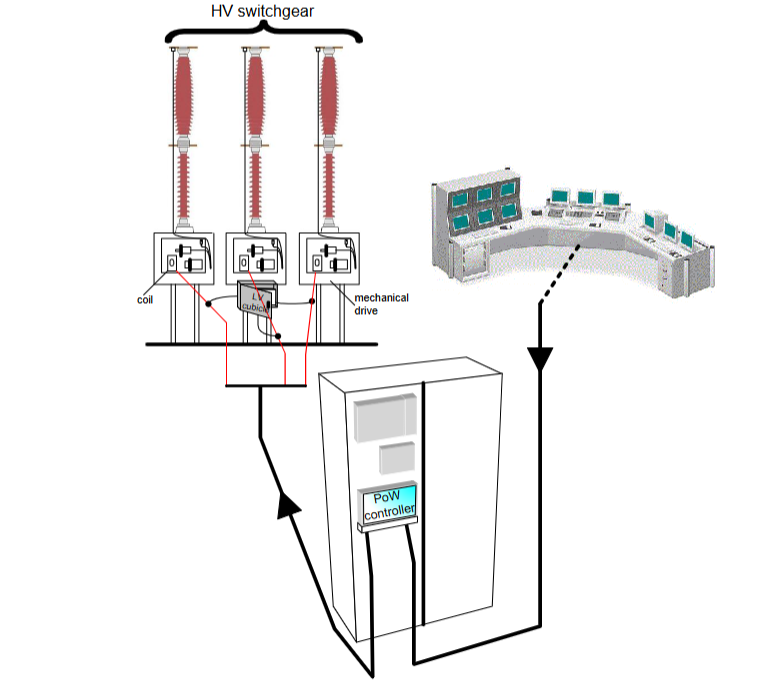

This manual is the service manual for the RPH3 "Point on Wave (PoW)" controller, which is used to guide the synchronous switching operation of high-voltage switchgear and support equipment understanding, installation, use, and maintenance.

Copyright belongs to GE Grid Solutions. The content is informative and can be adjusted according to technical and commercial needs. Unauthorized reproduction and disclosure are prohibited.

Reference architecture

GE internal documents: such as D1621EN (User Manual), D1622EN (RPH Manager Software Manual), etc.

International standard: Following IEC 62271-302 (Non synchronous pole operation of high-voltage switchgear).

Industry Report: Cited from CIGR É 262-264 publication (HVAC Switchgear Control Switching Guide).

Safety and Operation Instructions

Static Electricity and Electrical Safety

Electrostatic discharge (ESD) may damage equipment and should comply with anti-static standards such as EN 61340-5-1.

Power off before operation, confirm that the power supply voltage is compatible (AC 100-240V or DC 48-353V), only qualified engineers can operate.

Storage and installation requirements

Store in a dust-free and dry environment at -40 ℃~+70 ℃, with moisture-proof bags retained; Installed in the control room or relay room, ensuring good grounding, away from vibration sources, supporting 19 inch rack or wall mounted installation.

Principle of PoW Switching Technology

Random switching vs synchronous switching

Random switching: When the coils are powered on simultaneously, it is easy to generate surge current and overvoltage, which can cause equipment aging or protection misoperation.

PoW switching: By delaying the control of coil energization time, the high-voltage contacts are made to contact at the target point of the voltage waveform (such as zero crossing or peak), reducing transient phenomena. For example:

Inductive load (transformer) closing selects peak voltage to reduce excitation inrush current;

Capacitive load (capacitor) closing selects voltage zero crossing to reduce charging current surge.

Key parameters and terminology

Pre arming Time: The current conduction time before the mechanical contact of the contacts during closing, influenced by the dielectric strength decay rate (RDDS).

Operating Time: The time it takes for the coil to be powered on until the contacts fully move, and it is necessary to compensate for the effects of environmental temperature, hydraulic pressure, and other factors.

Adaptive Control: Based on historical operational data, adjust control timing and compensate for unpredictable factors such as equipment aging.

RPH3 Hardware and Functional Architecture

Module composition

M1: Power module, providing internal DC power supply.

M2: Central processing and communication module, integrated with DSP and Linux system, supporting Ethernet and fiber optic communication.

M3: Analog acquisition module, sampling reference voltage, current, temperature, hydraulic pressure and other signals.

M4: Signal and coil drive module, processing switch commands and relay outputs.

M5: Front panel management module, controls LED indicator lights and serial communication.

Core functional modules

Reference voltage sampling: Obtain the grid voltage through VT as a timing reference, supporting L1/L2/L3 phase selection.

Neutral point mode detection: supports hardware jumpers (M4-J5) or software settings to distinguish between grounded, isolated, or unknown modes.

Coil driver: Supports common mode/differential mode wiring, outputs 80ms adjustable pulses, and drives the opening and closing coils of switch devices.

Operation time measurement: Detect contact action through auxiliary contacts or current transformers (CT) with an accuracy of ± 0.1ms.

Compensation mechanism and adaptive control

Compensation factors for operation time

Environmental temperature: Low temperature will prolong operation time. Real time compensation can be achieved through a temperature sensor (4-20mA input), and the compensation meter can be configured through Web MMI.

Control voltage: Voltage fluctuations affect the rate of rise of coil current. The compensation value is calculated using the formula Δ t voltage=(U meas U rate − 1) ⋅ kU ⋅ t OP_rated, where kU is the compensation coefficient (to be measured).

Hydraulic pressure: For hydraulic drive mechanisms, real-time sampling is carried out through pressure sensors, and compensation is made according to Δ t pressure=(P meas P rate − 1) ⋅ kP ⋅ t OP_rated.

Idle time: Devices that have not been operated for a long time will slow down, compensated by the exponential function Δ t idle=A ⋅ (1 − e − BT idle), where A and B are empirical parameters.

Adaptive control is based on historical operational data and utilizes Δt adapt=K⋅(t measured −t commissioning −Δt compensations)+(1−K)⋅Δt adapt_prev Adjust the prediction time series, with K as the weight factor (default 0.3).

Alarm and Data Management

Alarm Type

System alarm: such as abnormal power supply, hardware failure, calibration failure, etc., triggering the red LED "3" on the front panel.

Application alarm: If the reference voltage exceeds the limit, the operation time is abnormal, the compensation value exceeds the limit, etc., the LED "4" will be triggered.

Relay output: 5 relays (1 monostable+4 bistable), which can be configured with alarm correlation logic through Web MMI.

Data recording and communication

Real time data: View parameters such as voltage, current, temperature, etc. through Web MMI, with a refresh rate of 3 seconds or 20 seconds.

Switching record: Stores the last 1025 operation data ("*. arch" file), supports downloading waveforms and event logs through RPH Manager software.

Network interface: Supports IP network (default IP 192.168.5.2), compatible with IEC 61850-9-2 communication protocol.

Application scenarios and switching strategies

Typical load switching scheme

Transformer/Three core Reactor:

Closing: Select the peak voltage (90 ° electrical angle) for the grounding neutral point, and select 0 ° or 180 ° for the isolation neutral point.

Trip: Select the current zero crossing point (corresponding to the peak voltage) to reduce overvoltage.

Single core reactor: The closing target point is the same as the transformer, and the tripping strategy is consistent.

capacitor:

Closing: Select voltage zero crossing (0 °) for the grounding neutral point and phase voltage zero crossing for the isolation neutral point.

Trip: Select the zero crossing point of the current to avoid heavy impact.

Transmission line:

Inductive VT: select voltage zero crossing for closing;

Capacitive VT: It is necessary to evaluate the residual charge in the circuit and select the peak voltage for closing.

Inductive load with NGR: Select the neutral point mode based on the inductance ratio r=LL N, and use a custom switching program when r ≥ 0.3.

Switch program configuration

Built in preset programs (transformers, reactors, capacitors), supporting user-defined modes (User Mode), can adjust the angle offset of each phase.

Technical parameters and specifications

Physical characteristics: 19 inch 4U rack, dimensions 483 × 177 × 452mm, protection level IP20.

Electrical parameters:

Power supply: AC 100-240V/50-60Hz or DC 48-353V, power consumption<20W;

Coil driving voltage: DC 33-300V, maximum current 30A (300ms).

Measurement accuracy: Voltage/current sampling error ≤ 1%, operation time measurement error ≤ ± 0.1ms.

Environmental adaptability: Operating temperature -25 ℃~+50 ℃, storage temperature -40 ℃~+70 ℃, compliant with RoHS and EMC standards (such as IEC 61000-4-2/3/5).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923