K-WANG

ABB S500 heavy-duty circuit breaker

ABB S500 heavy-duty circuit breaker

Product Overview

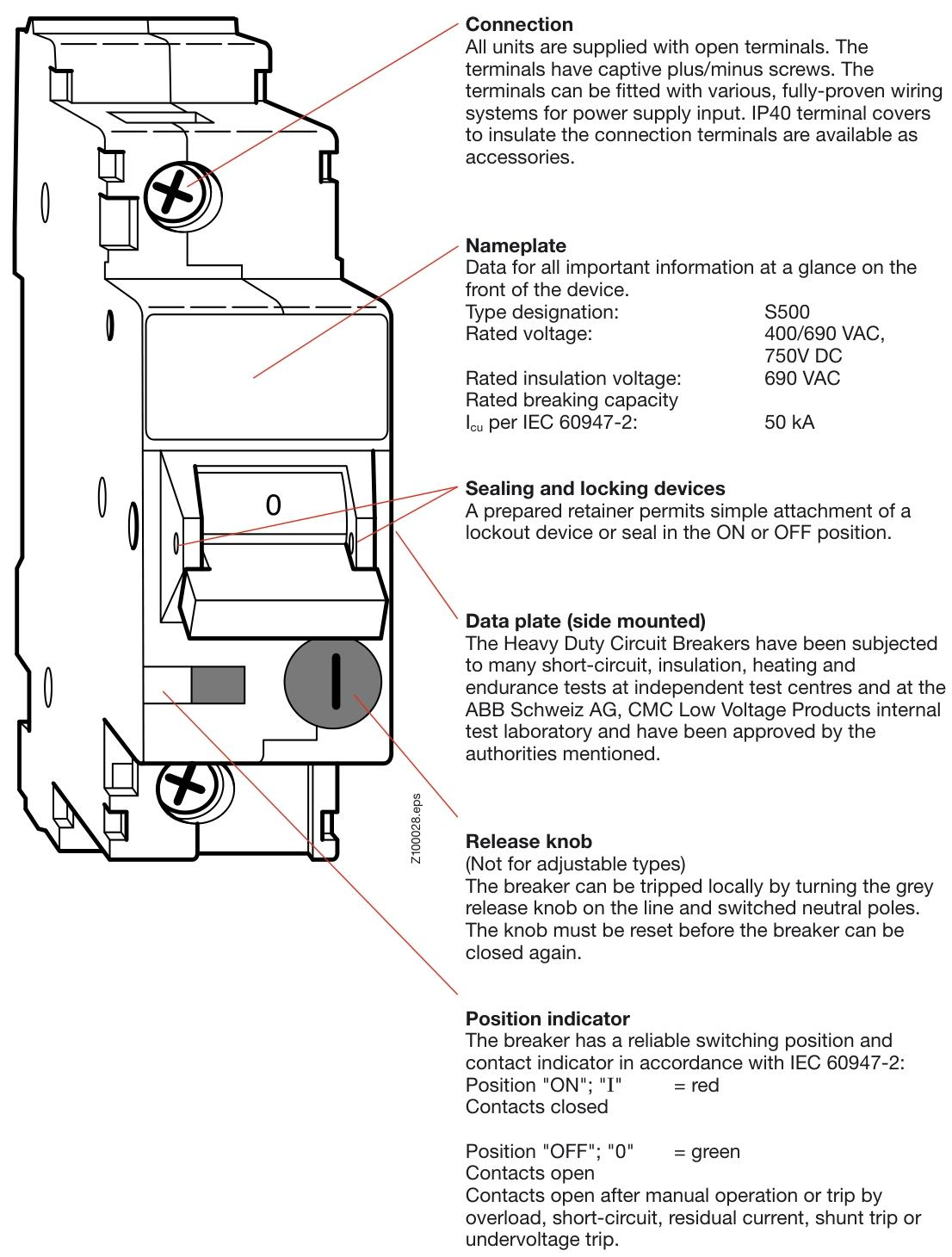

The ABB S500 series heavy-duty circuit breaker is a protective switchgear designed to meet the increasing demand for short-circuit current in low-voltage power grids, with high safety, reliability, and breaking capacity. Its core function is to protect circuits, motors, equipment, and systems from the effects of overload and short-circuit currents through thermal and/or electromagnetic trip functions. It is widely used in various fields such as railways, commercial buildings, offshore platforms, ships, process industries, and rail trams.

Core Features

High performance parameters:

High rated breaking capacity, up to 30/50 kA.

High rated working voltage, AC 400/690 VAC, DC 750 VDC.

Equipped with current and energy limiting breaking capabilities, the breaking time is extremely short, ensuring system safety.

Functional advantages:

Excellent selectivity ensures that only the faulty part is disconnected in the event of a malfunction, while maintaining the operation of other parts of the system.

The switch and contact position indication are reliable and convenient for status monitoring.

Provide multiple special application versions to meet the needs of different scenarios.

Compact in size (compliant with DIN standards), with a wide range of accessories including undervoltage release, shunt release, auxiliary contacts, and signal contacts.

Main product types and applications

Circuit protection series:

S500-B: Suitable for equipment with no or only minimal surge current (such as boilers, electric heaters, etc.).

S500-C: Standard type, suitable for devices with surge current (such as inductive devices, sockets, etc.).

S500-D: Suitable for devices with extremely high surge currents (such as transformers, capacitor banks, etc.), and can also be used as protection for upstream circuit breakers.

Motor protection series:

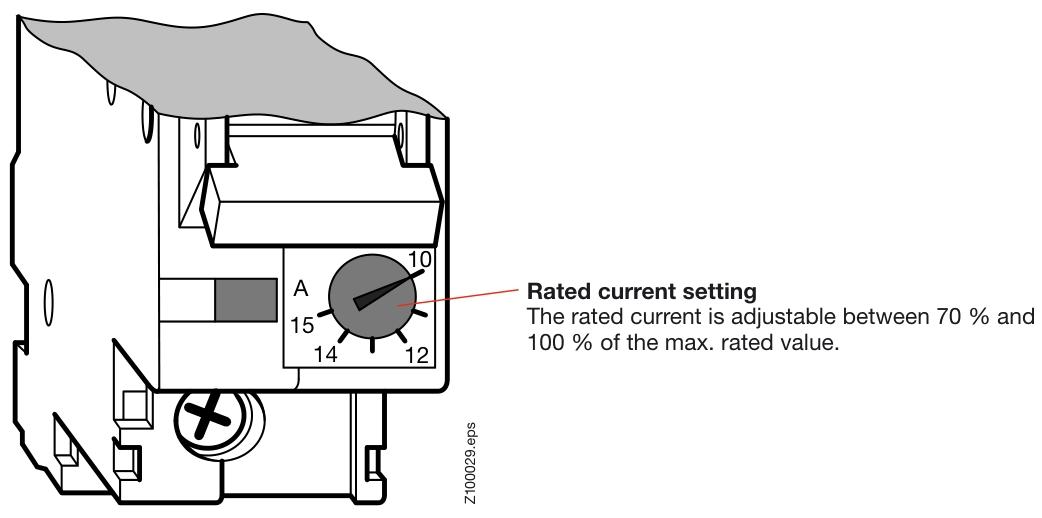

S500-K: Used to protect single-phase and three-phase motors, can be installed in a fuse free motor control center, with adjustable rated current.

S500-KM: It only has electromagnetic trip function and needs to be combined with independent overload protection to provide short circuit protection for the motor.

S503X-AG0084: Alternative to S500-KM, with high breaking capacity (50 kA at 400 VAC), suitable for high short-circuit current scenarios.

DC Circuit Protection Series (S500UC-B/K):

Suitable for DC applications such as railway systems, electroplating, and DC networks. Single pole can switch to 250 VDC, and multi pole series can switch to 750 VDC+20%.

It is divided into fixed rated current (B characteristic) and adjustable rated current (K characteristic) versions.

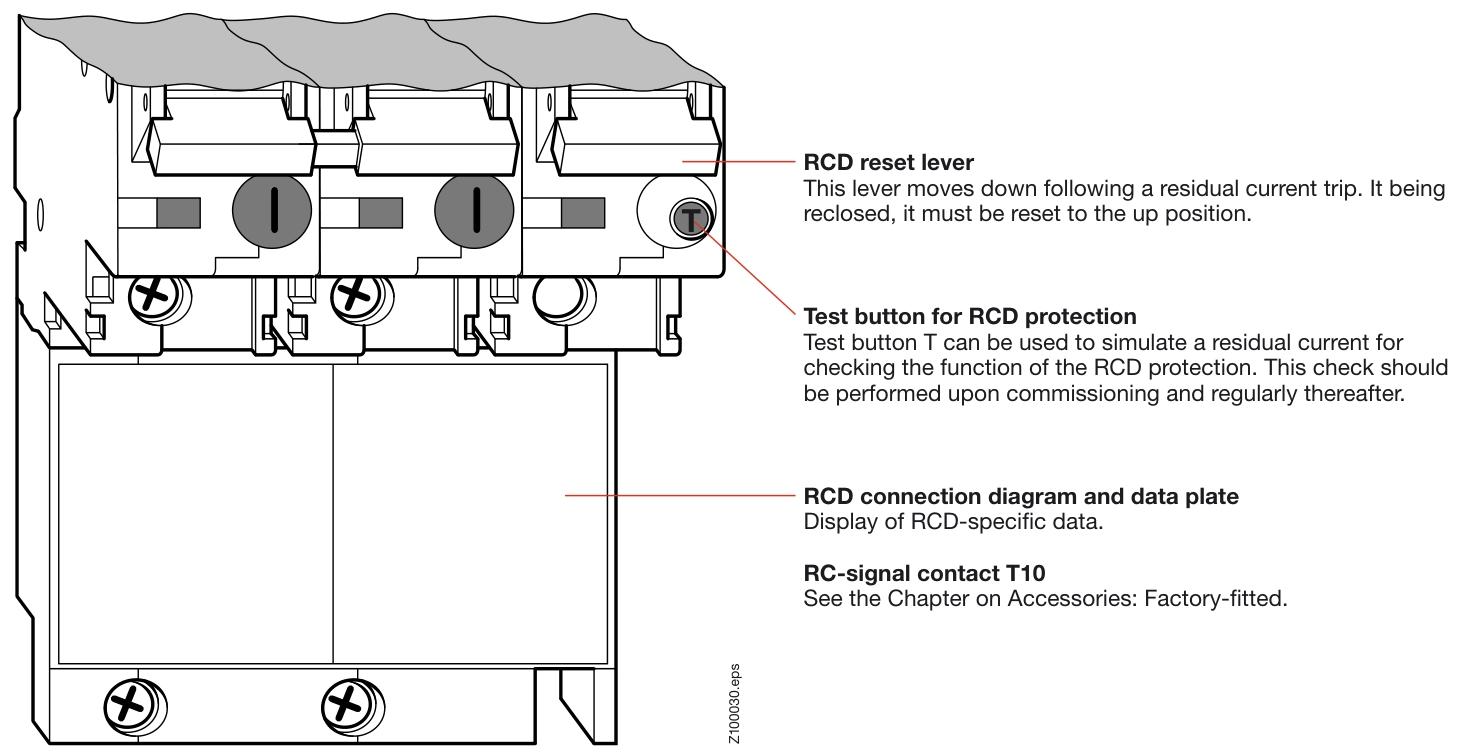

Residual current protection series:

F500-C/D: It has both circuit protection and residual current tripping functions, and can protect against direct contact, dangerous residual current, etc.

F500-K: Equipped with motor protection features and residual current trip function, suitable for motor systems.

DDA series: can be installed by users on S500 circuit breakers, suitable for sine AC residual current and pulse residual current scenarios in DC circuits.

Short delay/selective residual current protection: F500K... 0.03 G (short delay type) and F500S... 0.3 S (selective type), respectively used to avoid false tripping and ensure selectivity with downstream equipment.

Technical parameters and characteristics

Electrical parameters:

The rated current range is wide, covering 0.1 A to 63 A (some models have higher ratings).

The rated breaking capacity varies depending on the model and application scenario, and can reach up to 50 kA.

The working frequency covers 50/60 Hz, and can support 16 ²/∝ Hz and 400 Hz under special requirements.

Environment and Installation:

Allowable ambient temperature -25 ° C...+55 ° C, storage temperature -25 ° C...+70 ° C.

Protection level IP20, flexible installation method, can be installed at any angle, supports up and down incoming lines.

Long mechanical lifespan, with a switch frequency of over 20000 times.

Selective and Backup Protection

Selectivity: By properly coordinating the upper and lower circuit breakers, ensure that only the faulty part is disconnected during a short circuit. The document provides selective coordination parameters with upstream circuit breakers, backup fuses, and downstream miniature circuit breakers.

Backup protection: When the short-circuit current at the installation point exceeds the breaking capacity of the circuit breaker, it is necessary to configure according to the rated current limit of the upstream circuit breaker. The document provides specific backup protection parameters and cable length requirements.

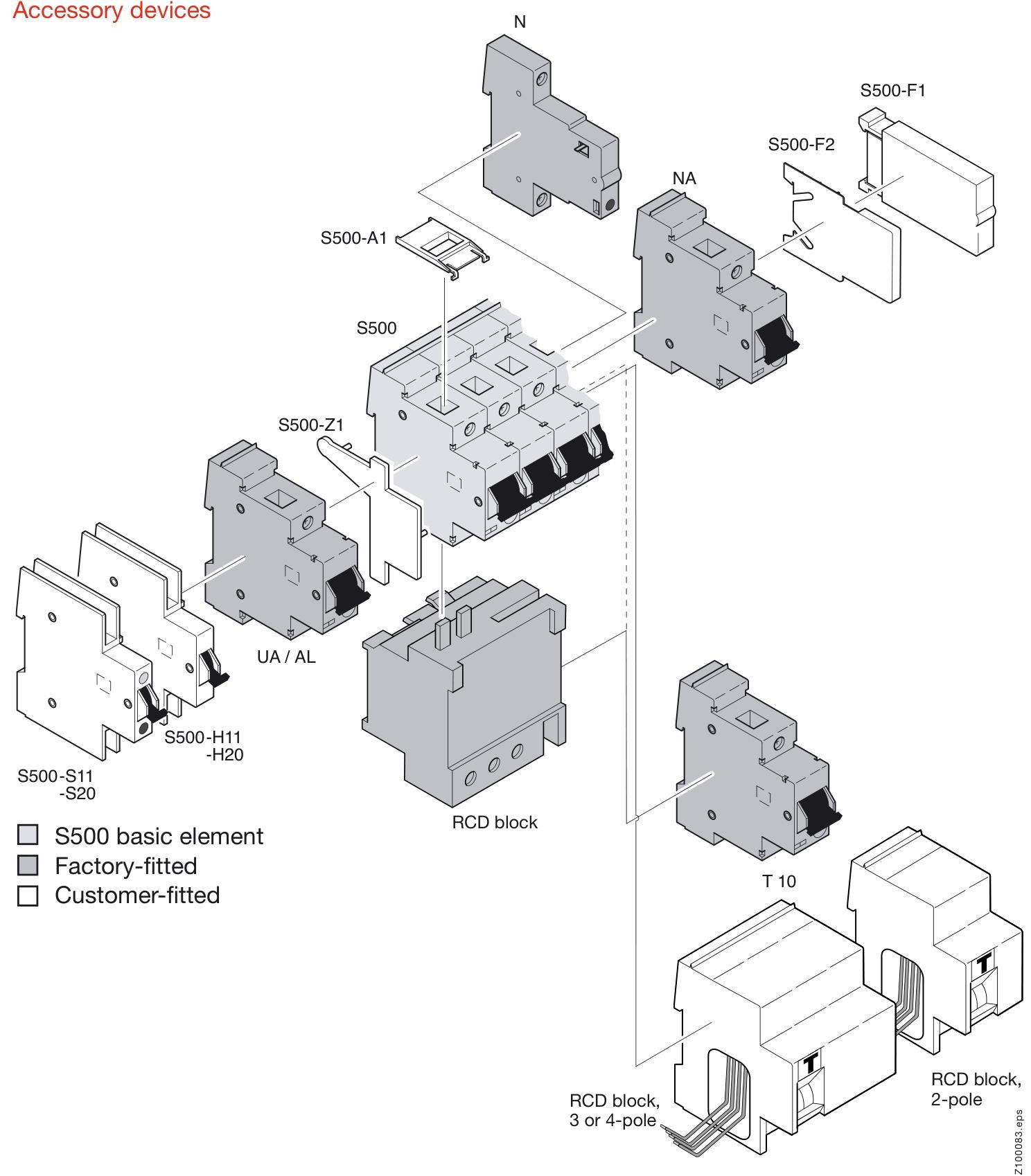

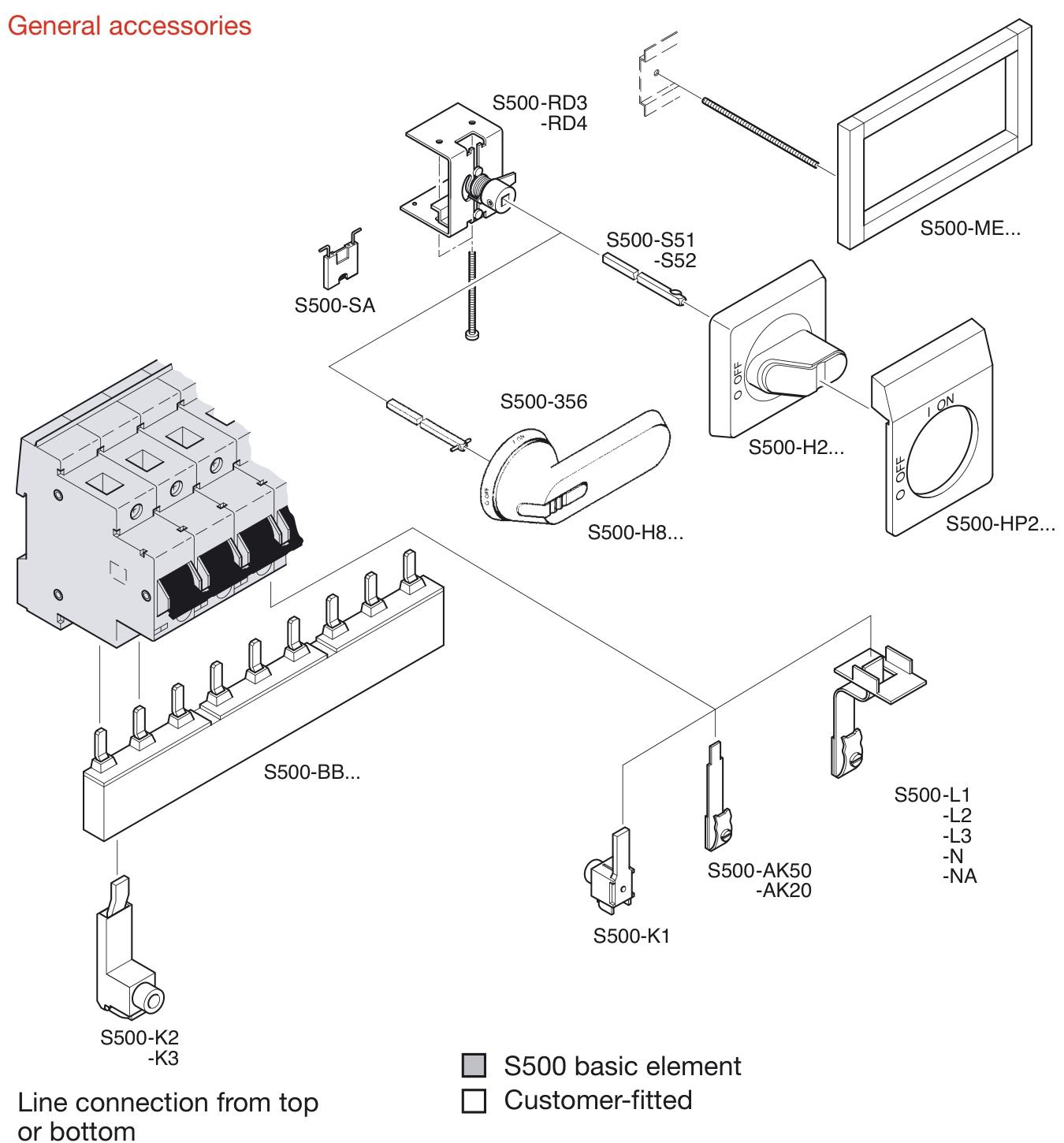

Accessories and Installation

Accessories: including factory pre installed accessories (such as switching neutral wire NA, separating neutral wire N, release, residual current signal contacts, etc.) and user installable accessories (such as auxiliary contacts, signal contacts, locking devices, rotary drives, etc.).

Installation: 35 mm standard rail clip shall be used for installation, and the safety spacing requirements shall be followed. When cleaning, use a vacuum cleaner or wet rag (soap lotion), and avoid using compressed air or high-pressure cleaner.

Standards and Certification

Compliant with multiple international standards such as IEC 60947-2, UL 1077, CSA, etc., certified by CE, cULus, FM, etc., ensuring product quality and compliance.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- xYCOM

- Construction site

- Siemens

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Motorola

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive