K-WANG

SINUMERIK System 800 General Interface Planning Guide

SINUMERIK System 800 General Interface Planning Guide

The SINUMERIK System 800 Universal Interface Planning Guide (December 1995 edition) is a technical document aimed at machine tool manufacturers, supporting multiple series of control systems such as SINUMERIK 805/810/820/840/850/880. The core content covers the technical specifications of V.24 (RS232C), 20 mA current loop, and RS 422 serial interfaces (signal definition, level polarity, drive receiving module), interface adaptation (pin allocation, transmission format setting), data transmission timing (line control/character control equipment), interface configuration of various models of control systems, as well as practical connection schemes (cable models, parameter settings, wiring diagrams) for more than 30 types of I/O devices such as printers, tape drives, and programmers. It also clarifies different types of I/O devices. The maximum transmission distance of the interface, electromagnetic compatibility requirements, and equipment adaptation principles.

Three core interface technical specifications

2.1 V.24 (RS232C) interface

Signal definition: Following DIN 66020/CCITT V.24/V.28 standard, including data line (D1=TxD, D2=RxD), control line (S2=RTS, S1.2=DTR), message line (M1=DSR, M2=CTS), grounding line (E1=protective ground, E2=signal ground).

Level and polarity: The logic L of the data/control signal is+3~+15V, the logic H is -3~-15V, the signal reference ground is E2, and the transition interval (± 3V) state is undefined.

Drive and receive modules: Drive module 75188 (power supply ± 15V, maximum output current 10mA), receive module 75189 (maximum input voltage ± 30V, input resistance 390 Ω).

Transmission restriction: The maximum cable length is 30m and cannot be connected simultaneously with a 20mA interface.

2.2 20 mA current loop interface

Signal characteristics: transmitted as a current signal, with logic L corresponding to 20mA (± 30%), logic H corresponding to 0-2mA, and SINUMERIK providing a 12V current source.

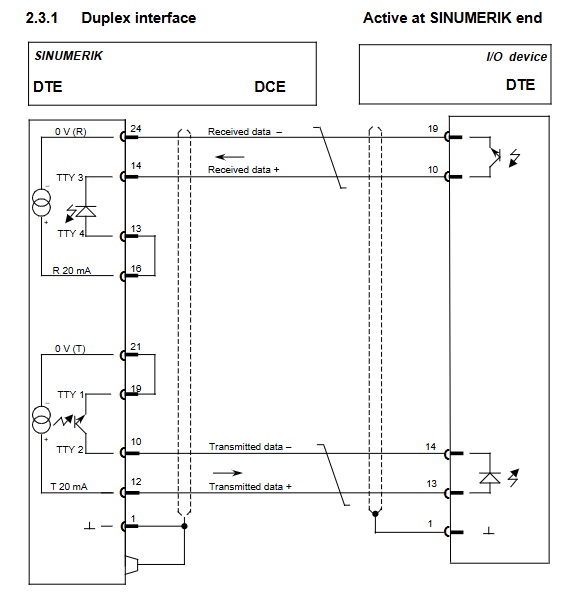

Working mode: Duplex dual line pair, supporting SINUMERIK active (providing current)/passive (external device providing current) mode, switched through cable pin allocation.

Device connection: It is necessary to distinguish between active/passive mode wiring, and verify the 20mA current value when closing the circuit, which is equivalent to the V.24 signal function (TxD=TTY2, RxD=TTY4, etc.).

Transmission limit: Maximum cable length of 1km.

2.3 RS 422 interface

Core advantage: Combining the modulation and demodulation control capability of V.24 with the long-distance transmission advantage of 20mA, adopting dual line differential transmission.

Level specification: Drive output VoL ≤ 0.5V, VoH ≥ 2.5V, differential voltage 2~5V, reference AM26 LS 31/33 module voltage.

Drive and receive: AM26 LS 31 drive module (powered by 5V), AM26 LS 33 receive module (input parallel resistance of 150 Ω).

Extension function: Supports level conversion from V.24 to RS 422 (dedicated cable integrated converter), with a maximum transmission distance of 1km.

Interface adaptation and configuration

3.1 Pin allocation

Interface type, connector specifications, key pin functions

V. 24/20mA universal 25 pin D-Sub socket V.24:2=* TxD, 3=* RxD, 4=RTS, 5=CTS; 20mA:10=TTY2、12=T 20mA、13=TTY4

RS 422 25 pin D-Sub socket 2=* TxD, 3=* RxD, 4=RTS, 5=CTS, 15=TxD, 16=RxD

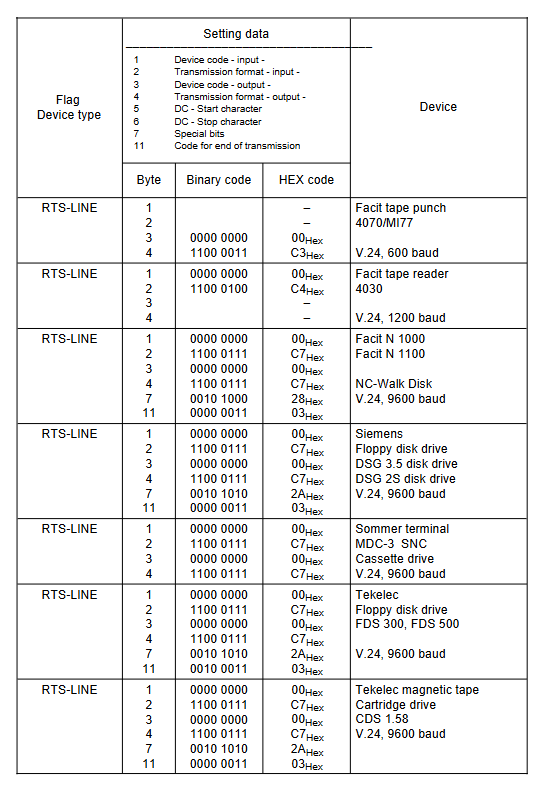

3.2 Transmission Format Settings

Core parameters: 15 byte set data, including device encoding (line control/character control/dedicated equipment), transmission format (baud rate 110~9600 baud, parity (presence/absence/parity), stop bits (1/1.5/2)).

Special configuration: Xon/Xoff character definition, EIA code special character substitution (@/:/=, etc.), transmission termination character setting.

Adaptation principle: Line control equipment relies on DSR/DTR/CTS/RTS lines, character control equipment relies on Xon/Xoff characters, and uncontrolled equipment adopts asynchronous transmission.

3.3 Data transmission timing sequence

Line control equipment: When inputting, NC confirms equipment readiness through DTR/DSR, and RTS controls data reception; When outputting, NC confirms that the device buffer is idle through CTS, and the transmission terminates at ETX or program end.

Character control device: When inputting, NC sends Xon to allow data transmission, Xoff pauses; When outputting, NC starts transmission after receiving Xon, and supports direct startup without first Xon (set byte 7 bit 7).

Key time limit: timeout monitoring defaults to 60 seconds (can be turned off) to avoid transmission lag.

Interface configuration of each control system

Control system model, interface quantity, interface type, special instructions

SINUMERIK 805 1 standard+1 optional standard V.24/20mA, optional V.24 (supports RS422 conversion) 25 pin D-Sub socket

SINUMERIK 810 GA3/820 GA3 1 standard+1 optional standard V.24/20mA, optional V.24 (supports RS422 conversion) operation panel front and rear interface

SINUMERIK 840 1 standard+1 optional standard V.24/20mA, optional V.24 (supports RS422 conversion) machine control panel front-end interface

SINUMERIK 850 supports up to 4 V.24/20mA/RS422 central controllers+operation panel interfaces

SINUMERIK 880 supports up to 4 V.24/20mA/RS422 slot configurations to distinguish different models

Practical Connection Scheme for I/O Devices

5.1 Equipment Classification and Adaptation List

Covering over 30 types of devices, the core categories include:

Printing equipment: Siemens PT 80/PT 88 printer

Magnetic tape/floppy disk devices: SINUMERIK T30/T40/T50/T60 tape drive, Siemens DSG 3.5/2S floppy disk drive

Programming equipment: SIMATIC PG 670/675/685/750 programmer

Data carrier: GNT 7101 NC data carrier CAN NC Recorder FD/FH

Workstation: SINUMERIK WS 800/WS 800A Programming Workstation

5.2 Connection Core Parameters (Example)

Equipment Name Interface Type Baud Rate Cable Model Key Settings

Siemens PT 80 printer V.24/20mA 300 baud 6FC9 340-8C (V.24) 8 data bits, 2 stop bits

SINUMERIK T60 tape drive V.24 9600 baud 6FC9 344-2C DIP switch 8-position OFF

SIMATIC PG 750 programmer V.24 9600 baud 6FC9 344-4R even parity, 2 stop bits

RS 422 conversion from V.24 to RS422 adaptation device 6FC9 344-2VZ maximum transmission 100m

5.3 Cable and wiring requirements

Cable specification: Shielded cable (such as 8 × 2 × 0.18mm ²), with power and control lines laid separately.

Grounding requirements: The shielding layer is grounded at both ends, and the protective grounding (E1) complies with DIN VDE 0160 standard.

Ordering information: Clearly specify the cable ordering number and maximum length (mainly 30m, some up to 100m) for each type of equipment.

Key specifications and precautions

Electromagnetic compatibility: Follow VDI 2880 guidelines, cable grouping and routing to avoid interference.

Equipment adaptation: The connection between DTE equipment (SINUMERIK) and DTE equipment requires cross wiring (sending → receiving).

Encoding conversion: Missing characters (such as @/:) in EIA codes need to be replaced by setting data definitions.

Transmission restrictions: Strictly adhere to the maximum transmission distance of each interface, and use RS 422 or conversion scheme for exceeding the distance.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

-

KEBA E-CG-CONTROL - ECGCONTROL Module

-

KEBA Kemro K2-200 OP350/W 68334 - Engel EC200 Panel Membrane Touch Glass

-

KEBA i1075 - Membrane Keyboard

-

KEBA E-HSI-M - Interface Module

-

KEBA LQ10D321-ERSAT - ZTEILSET FNOB

-

KEBA E-16-DIGOUT/G - Circuit Board

-

KEBA HT4/Neutral/16846 - Mikron Handheld Terminal

-

KEBA KeTop CB310-000 - Connection Box

-

KEBA DC 161/IP20/17369 - Interface Card Module

-

KEBA E-16-DIGOUT-PLUS - Elektronik Bau Linz 262-1456-85-B

-

KEBA HT501 - Handheld Terminal

-

KEBA HT401-4X20 - Teach Pendant

-

KEBA E-3-ACU-10 D16738 - Controller Card Module

-

KEBA 240/A 068371 - Analog Output Module

-

KEBA E-7TEMP D1323E/F/G - Temperature Circuit Board

-

KEBA KeTop TT100-eaa - Communication Cable

-

KEBA E-16 DIGOUT-PLUS D1456D - Engel Output Board

-

KEBA Kemro K2-200 - Touch Panel Glass Digitizer

-

KEBA CC100A03/CAN/4 - PLC Chassis 16-Slot Rack Motherboard 1842E-0

-

KEBA CU 211 - PLC Power Supply

-

KEBA KeTOP CB310-S00 - Connection Box

-

KEBA I/O BUS KOPPLUNG D1547C - Engel Circuit Board

-

KEBA HCS01.1E-W0013-A-02 - Servo Drive

-

KEBA SMC1-Z30 - LTI Security Safety Control

-

KEBA E-PS88-M/C D1527C - Power Supply Board

-

KEBA D1678C / E-SEK - Control Board

-

KEBA 1.83E+02 - Circuit Board Module

-

LUST LTI/KEBA DSM4-05.4-20R.96-W1A - AC Servo Motor

-

Engel/KEBA OP 362-LD/W-5200 - Kemro Ke-200 Membrane Keypad Touch Screen

-

KEBA HT4 24V/0.2A - Kammann Hand Terminal C3052-R47

-

KEBA Kemro K2-200 BL210/B - Injection Molding Machine Controller Module

-

KEBA E-8-ANALOG D1432B - Analog Board

-

KEBA DM272 - Input Output Module

-

KEBA AR161 - PCB ML-EUMIG

-

KEBA E-PS-24V 1825E-1 - Power Supply Board

-

KEBA E-8-THERMO 1770B-1 - Engel Temperature Control Board

-

KEBA HT4-221-20556 - Kammann Hand Terminal

-

KEBA E-10-ANALOG-SUB D1458D - Circuit Board

-

KEBA AC 441 - Control Module 18-32 VDC

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA E-ANA-SUB2 D1690C - Analog Submodule Card

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad

-

KEBA OP 331/C-4400 - Keview V2 LCD Display Screen Panel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923