K-WANG

SIEMIENS SIPART PS2 (6DR5...) Electrical Positioner Operation Guide

SIEMIENS SIPART PS2 (6DR5...) Electrical Positioner Operation Guide

Basic and Product Overview

Overview

The compact operation guide for SIPART PS2 (6DR5...) electric pneumatic positioner covers core contents such as product introduction, safety instructions, installation and mounting, connection, debugging, maintenance, technical parameters, and appendices. It is clear that the positioner is suitable for continuous control of process valves in multiple industries such as chemical, oil and gas, and energy. It emphasizes that the use in hazardous areas must comply with explosion-proof standards (such as ATEX, IECEx), and installation and debugging must follow specific steps (such as automatic/manual initialization). At the same time, detailed technical data (such as working temperature -30~+80 ° C, protection level IP66) and adaptation information for each module (alarm, position feedback, etc.) are provided to ensure safe and compliant operation of the equipment.

Product Usage and Compatibility

Usage: Used in 8 major industries including chemical, oil and gas, energy, food and beverage, papermaking, water supply and drainage, pharmaceuticals, and offshore platforms to achieve continuous control of valves in pneumatic drive processes

Compatibility: Different document versions need to match specific device firmware (FW) and integrated software versions, as shown in the table below:

Communication protocol document version, device firmware requirements, compatible with integrated software (including EDD version)

HART 05/2018 FW: 5.01.00 and above; Device version 6 and above SIMATIC PDM V9.0(EDD:23.00.00+)、AMS Device Manager V12.5(EDD:23.00.00+) wait

PROFIBUS PA 05/2018 FW: 6.00.00 and above SIMATIC PDM V9.0 (EDD: 22.00.00+), SITRANS DTM V4.1 (EDD: 22.00.01+), etc

FOUNDATION Fieldbus 05/2018 FW: 3.00.00 and above; Device version 3 SITRANS DTM V4.1(EDD:3.00.00+)、AMS Device Manager V12.5(EDD:3.00.00+) wait

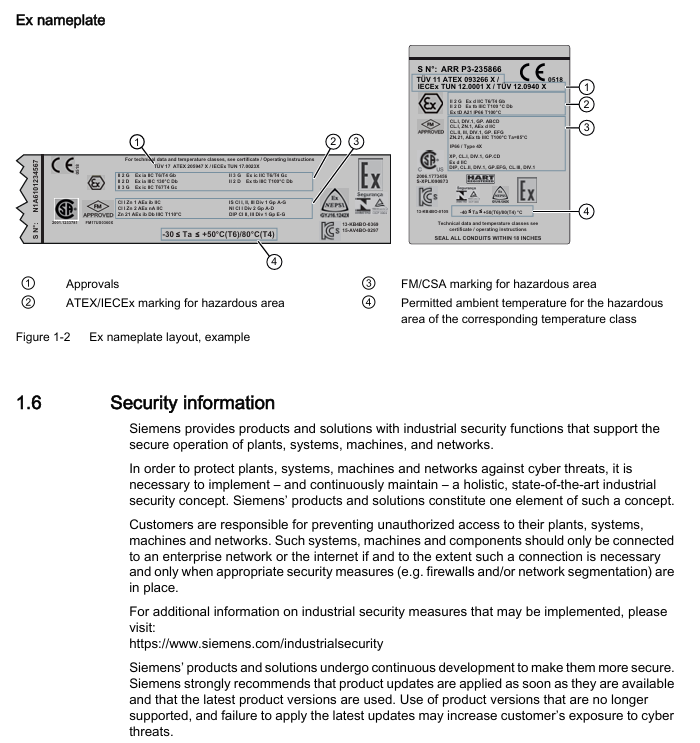

Goods inspection and nameplate

Goods inspection: After receiving the goods, it is necessary to check whether the packaging/items are damaged and verify the consistency between the order and the shipping documents; Prohibit the use of damaged or incomplete equipment (there is a risk of explosion in hazardous areas)

Nameplate information: including key information such as manufacturer, protection level (e.g. IP66), software and hardware versions, explosion-proof identification (e.g. Ex d IIC T6/T4), serial number, etc. The explosion-proof nameplate needs to be additionally labeled with ATEX/IECEx/FM/CSA certification information

Safety instructions (core risk prevention and control)

Warning level system

DANGER: Failure to take preventive measures may result in death or serious personal injury

Warning: Failure to take preventive measures may result in death or serious personal injury

CAUTION: Failure to take preventive measures may result in minor personal injury

NOTICE: Failure to take preventive measures may result in property damage

Requirements for use in hazardous areas

Operator: Must have the qualification to operate equipment in hazardous areas and be familiar with electrical, high-voltage, and hazardous medium safety regulations

Explosion proof requirements: Only use equipment labeled with the corresponding explosion-proof level (such as II 2 G Ex d IIC T6/T4 Gb), and prohibit the use of equipment suitable for non hazardous areas; If the equipment has been used in non hazardous areas, its explosion-proof label must be permanently removed

Special Warning: The pneumatic terminal board of 6DR5. 6 locator is a safety component of explosion-proof shell, and its fixing screws must not be loosened

Other safety regulations

Equipment modification: Only modifications are allowed according to the document instructions. Unauthorized modifications will cancel the warranty and certification

Power requirements: It is necessary to connect a safety isolated Extra Low Voltage (SELV) to avoid voltage flashover; Dangerous area connection equipment must be carried out in a power-off state (except for Ex i version)

Cable requirements: Use cable glands/plugs that meet explosion-proof standards. Unused cable entrances must be sealed, and shielded cables are only allowed to be grounded at one end (when crossing hazardous areas)

Installation and mounting

Basic security prerequisites

Pneumatic actuators have high operating force and must follow their safety instructions; The mounting kit with position detection lever poses a risk of compression, and it is prohibited to insert limbs into the range of motion of the lever

Only use Siemens original accessories/spare parts to avoid the risk of explosion in hazardous areas; Before installation, confirm that there is no visible damage to the equipment and that the sealing gasket is correctly positioned to avoid damage during cover installation

Different mounting methods for actuators

Linear actuator: Use 6DR4004-8V mounting kit, suitable for stroke 3-35mm; for stroke exceeding 35mm, an additional 6DR4004-8L lever needs to be ordered

Angular stroke actuator: VDI/VDE 3845 mounting surface (thickness>4mm with reinforcement) needs to be provided on the actuator side, paired with 6DR4004-8D kit or TGX: 16300-1556 stainless steel coupling

Vibration/acceleration environment treatment

The equipment is equipped with a friction clutch and a gear lock with a transmission ratio selector to cope with strong vibrations/accelerations (such as emergency shut-off valves, steam shock scenarios)

Locking steps: Ensure that the gear lock is in the neutral position → Confirm the gear ratio selector (33 ° or 90 °) → Lock the gear lock with a 4mm screwdriver → Secure the friction clutch (non explosion proof shell version), ensuring that the gear ratio selector is set to the same position as the gear lock (to avoid position detection delay)

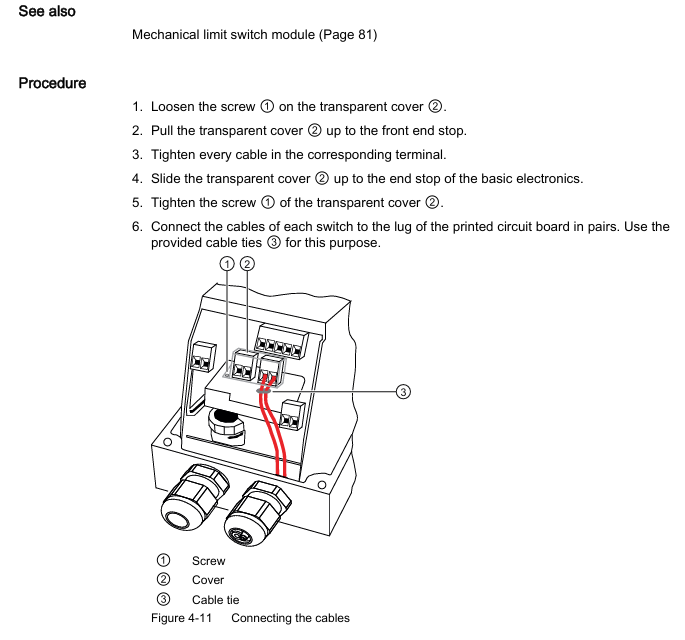

Optional module installation

Optional modules for standard/intrinsic safety versions: position feedback module, alarm module, SIA module, mechanical limit switch module, EMC filtering module, NCS sensor, internal NCS module

Optional modules for explosion-proof shell version: only supports position feedback module, alarm module, and internal NCS module; The internal NCS module is used for wear free position detection and is installed in the same slot as the position feedback module

Connection (electrical and pneumatic)

electrical connection

Basic requirement: When the environmental temperature difference exceeds 20 ° C, it should be left to stand for several hours before being powered on (to avoid condensation); When the ambient temperature is ≥ 60 ° C, cables with a temperature resistance of ≥ 80 ° C must be used; The 2-wire version prohibits connecting the voltage source to the current input terminal (I2w, terminals 6/7) and requires the use of a high impedance power supply

Wiring for different communication versions:

With/without HART: Supports 2/3/4 wire system, 2-wire current input 4-20mA (terminals 6+, 7-)

PROFIBUS PA: Bus circuit connection terminals 6/7, equipped with safety shutdown input (terminals 81+, 82-)

FOUNDATION Fieldbus: Bus circuit connection terminals 6/7, supporting simulation enable function

M12 connector adaptation: The M12 pins of different modules correspond to different functions, such as the 61+pin 1 (brown) and 62- pin 3 (blue) of the position feedback module 6DR4004-6J/8J

Pneumatic connection

Interface specifications: All are G ¼ or ¼ "NPT internal threads, Y1 is the driving pressure for single/double acting actuators 1, Y2 is the driving pressure for double acting actuators 2

Interface positions for different models:

6DR5. 0/1/2/3: The pneumatic interface is located on the right side of the locator, including Y1, Y2, air source PZ, and exhaust port with muffler

6DR5. 5/6 (Explosion proof enclosure): The pneumatic interface is on the right side, including Y1/Y2 flow restrictor, enclosure ventilation port, and exhaust port

Safe location settings:

When power is off: single acting actuator Y1 releases pressure; Double acting actuator Y1 applies pressure (maximum driving pressure) and Y2 releases pressure; Fail in Place actuator maintains the current pressure of Y1/Y2

Usage of flow restrictor: When the actuator travel time T>1.5s, rotate the Y1/Y2 flow restrictor clockwise to reduce the air output. It is recommended to close it first and then slowly open it. The double acting valve should ensure that the two flow restrictors are set close to each other

Debugging (Commissioning)

Basic safety precautions

Installation and connection must be completed before debugging in hazardous areas, and equipment must be turned off (except for Ex i version); If there may be water in the compressed air pipeline, the purge air selector should be set to "OUT" (then set to "IN" after drainage)

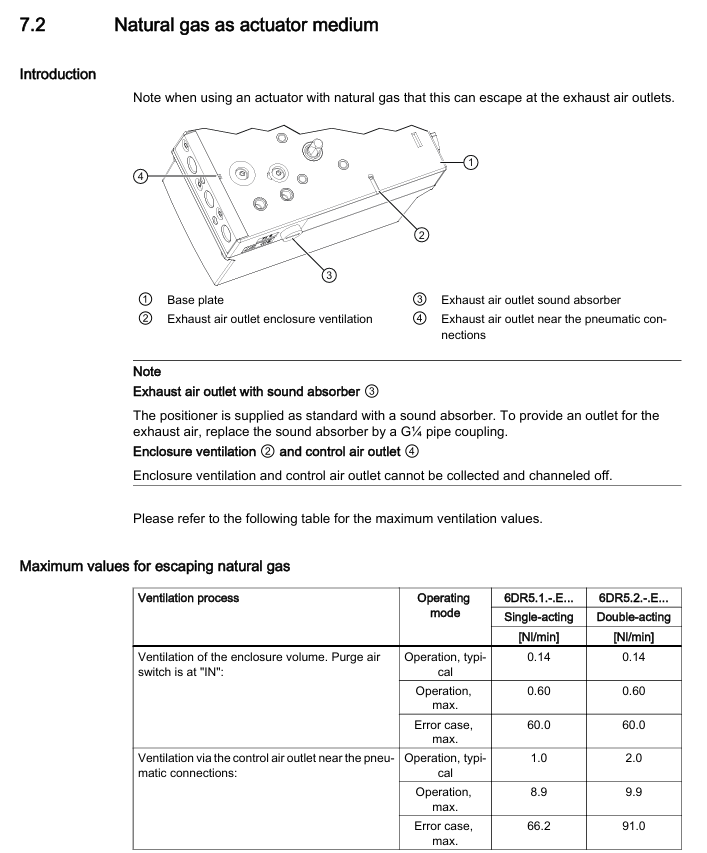

Special requirements for natural gas operation: Only intrinsically safe (Ex ia) equipment can be used; Prohibited from operating in enclosed spaces; Adequate ventilation is required (see technical data for maximum ventilation capacity); Prohibit the use of mechanical limit switch modules; Relieve pressure for at least 2 minutes before maintenance

Initialization type and process

Initialization type:

Automatic initialization: Automatically detect the direction of action, actuator stroke/rotation angle, stroke time, and adapt control parameters, with a time consumption of ≤ 15 minutes

Manual initialization: manually set stroke/rotation angle, and automatically detect other parameters (applicable to PTFE lined valves)

Data replication: Copy the initialization data of the original device when replacing it to avoid process interruption

Core parameters (1-5):

Parameter function applicable to actuators, optional parameter value units

1. YFCT action direction/detection type linear/angular stroke linear: WAY/- WAY/FWAY/- FWAY/LWAY; Angular travel: turn/- turn; NCS adaptation: ncSt/ncSL/ncSLL, etc-

2. YAGL locator shaft rated rotation angle stroke 33, 90 degrees

3. YWAY travel range (optional) Linear (WAY/- WAY/ncSLL/- ncLL) OFF, 5, 10, 15, 20 (33 ° short lever); 25, 30, 35 (90 ° short leverage); 40~130 (90 ° long lever) mm

4. InitiatA automatically initializes all NOINI (uninitialized) and Strt (start)-

5. InitiatM manually initializes all NOINI (uninitialized) and Strt (start)-

Automatic initialization steps for linear actuators:

Press and hold the button for 5 seconds to enter configuration mode → Call 2. YAGL to confirm consistency with the transmission ratio selector → Set 3. YWAY (optional) → Call 4. InitiatA and press and hold for 5 seconds to start → Display "FINSH" after completion

Automatic initialization of angular actuator: Similar to linear actuator, default 2. YAGL=90 °, and display the total rotation angle after initialization

Maintenance and upkeep

Basic security requirements

Only authorized personnel from Siemens are authorized to perform repairs; The surface area of equipment in hazardous areas with dust exceeding 5mm needs to be cleaned (to avoid overheating); When cleaning, use a damp cloth or neutral cleaner, and do not use solvents such as acetone (to avoid damaging the plastic/paint surface)

After maintenance, it is necessary to correctly connect the equipment and close the casing to ensure the explosion-proof level; Button lock only allows authorized personnel to cancel (to avoid parameter errors affecting process safety)

Filter cleaning (core maintenance item)

Cleaning methods for different shell materials:

Polycarbonate (6DR5. 0), Aluminum Shell (6DR5. 3), Explosion proof Aluminum Shell (6DR5. 5): Disconnect the air source → Remove the pipeline → Open the cover → Unscrew the 3 screws of the pneumatic terminal board → Remove the filter screen/O-ring → Clean with compressed air → Reinstall in the original order (polycarbonate shell screws are self tapping screws, need to first find the thread counterclockwise before tightening)

Stainless steel shell (6DR5. 2), explosion-proof stainless steel shell (6DR5. 6), single acting aluminum shell (6DR5. 1): Disconnect the air source → remove the pipeline → remove the metal filter → clean and reinstall

Repair and Disposal

Repair: The faulty equipment needs to be sent for repair along with the fault information, and the original equipment serial number needs to be provided when ordering replacement equipment; Prohibition of unauthorized repairs (cancellation of warranty and certification)

Return: Please provide the waybill, return documents, and proof of cleaning. If there is no proof of cleaning, a cleaning fee will be charged

Disposal: Compliant with the WEEE Directive (2012/19/EC), municipal waste disposal is prohibited and must be returned to the supplier or local compliant recycling agency

Technical data

General Parameters

Working conditions: temperature -30~+80 ° C (-40~+80 ° C with Z M40 order code), altitude ≤ 2000m, humidity 0~100%, protection level IP66 (NEMA 4X), anti vibration (2~27Hz: 3.5mm amplitude); 27~300Hz: 98.1m/s ² acceleration

Pneumatic data: Air source pressure of 1.4~7 bar (fault holding double acting 3~7 bar), air quality meets ISO 8573-1 (solid particle Class3, pressure dew point Class3, oil content Class3), valve leakage<6 × 10 ⁻⁴ Nm ³/h, controlled air consumption<3.6 × 10 ⁻² Nm ³/h

Various versions of electrical data (excerpt)

With/without HART: 2-wire system maintaining current ≥ 3.6mA; without HART version (6DR50.) typical load voltage 6.36V (318 Ω), maximum 6.48V (324 Ω); The typical load voltage for the HART version (6DR52.) is 8.4V (420 Ω), with a maximum of 8.8V (440 Ω)

PROFIBUS PA/Foundation Fieldbus: Bus voltage 9~32V (intrinsic safety type 9~24V), current consumption 11.5mA ± 10%, safe shutdown input (terminal 81/82) electrically isolated from the bus circuit

Optional module parameters (excerpt)

Alarm module (6DR4004-6A/8A): 3-channel binary output, intrinsically safe maximum input 30V/100mA/1W, signal high level>2.1mA, low level<1.2mA

Position feedback module (6DR4004-6J/8J): 4-20mA current output (2-wire system), transmission error ≤ 0.3%, temperature impact 0.1%/10K, intrinsic safety type only applicable to T4 temperature level

Mechanical limit switch module (6DR4004-6K/8K): 2 limit contacts, maximum switch current 4A (AC/DC), intrinsic safety maximum voltage 30V, UL certified version (6DR4004-6K) maximum voltage 30V AC/DC, 8K version without UL certification

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923