K-WANG

Siemens SIPROTEC 4 series protective relay

Siemens SIPROTEC 4 series protective relay

The core products of Siemens SIPROTEC 4 series protective relays (including models such as 7SJ61/62/64/66) cover multiple protection functions such as overcurrent, distance, and differential, and support multi protocol communication such as IEC 61850/IEC 60870-5-103. They have flexible protection configuration, synchronous switching, fault recording, and positioning characteristics, and are suitable for multiple scenarios such as medium and high voltage power grids, motors, transformers, and busbars. Combined with DIGSI 4 engineering software and SIGRA fault analysis tools, they can achieve full lifecycle protection, control, and monitoring.

Overview of Product System

1. Product classification and core models

Product Type Core Model Core Function Applicable Scenarios

Overcurrent protection relay 7SJ61 for non directional overcurrent, ground fault, motor protection circuit, motor, and transformer backup protection

7SJ62 direction overcurrent, flexible protection (20 group expansion), voltage/frequency protection for complex circuits, dual power supply

7SJ64 synchronization function, CFC expansion programming, fault location automation substation, multi switch control

7SJ66 Local Control, Multi Interface Communication, Local Protection for Small and Medium sized Substations

Distance protection relay 7SA522/6 series phase to phase/ground distance protection, power oscillation lockout transmission line, long-distance cable

Differential protection relay 7SD52/53/610 line differential, multi terminal differential short line, cable line

7UT612/613 Transformer/Generator Differential, Ratio Braking Transformer, Generator Transformer Unit

7SS52 distributed busbar differential, circuit breaker failure protection busbar protection, complex wiring method

Other specialized relays 7UM62 for comprehensive protection of generator and transformer units, demagnetization/step loss protection for generators and transformer units

7VK61 circuit breaker management, end fault protection circuit breaker control, breaker-a-half wiring

2. Core advantages

Function integration: Single device integration of protection, control, measurement, and diagnostic functions, supporting the principle of "one feeder, one relay".

Flexible Expansion: 7SJ62/64 supports 20 sets of flexible protection functions, and can customize trigger logic such as current/voltage/power.

Safe and reliable: Complies with standards such as IEC 60255 and ANSI C37.90, and has self-monitoring and trip circuit monitoring functions.

Open compatibility: Supports multi protocol communication and is compatible with Siemens SICAM systems and third-party control platforms.

Detailed introduction of core functions

(1) Protection function

1. Basic protection function

Protection type core parameters/characteristic representative model

Overcurrent protection with definite/inverse time characteristics (ANSI/IEC standard), supporting cold load pickup for the entire range of 7SJ products

Ground fault protection sensitive type (minimum 0.001A), intermittent, directional, suitable for different grounding methods 7SJ62/64, 7SD series

Overload protection thermal model calculation (IEC 60255-8), supporting environmental temperature compensation 7SJ61/62/64

Automatic reclosing up to 9 times (1 fast+8 delayed), phase separation/three-phase reclosing 7SJ61/62/64

2. Special protection function

Synchronization related: synchronous inspection (voltage/frequency/phase difference monitoring), synchronous/asynchronous switching (considering circuit breaker mechanical delay), supporting 4 sets of parameter storage.

Equipment specialization:

Motor protection: Start time monitoring, locked rotor protection, restart lockout, bearing temperature monitoring (up to 12 sensors).

Transformer protection: excitation surge suppression (second harmonic braking), high impedance limited grounding fault protection.

Generator protection: demagnetization, stepping loss, reverse power, stator grounding (third harmonic) protection.

(2) Control and Automation

1. Control function

Switch control: Supports local (panel/button) and remote (SCADA/DIGSI 4) control of circuit breakers, isolating switches, and grounding switches, and supports single/dual command processing.

Permission management: Switch the priority of permissions to "LOCAL>DIGSI 4>REMOTE", and support key switch to switch between local/remote modes.

Interlocking function: Implement equipment interlocking (such as checking the position of the isolation switch before closing the circuit breaker) and switching sequence control through CFC programming.

2. Logic Programming (CFC)

No programming experience required, custom functionality can be achieved by dragging and dropping logic components (and/or/triggers/timers).

Support threshold judgment of measurement values, signal logic combination, user-defined alarms, and command output.

(3) Monitoring and Diagnosis

1. Measurement and recording

Measurement parameters: three-phase current/voltage, zero sequence component, active/reactive power, power factor, frequency, electrical energy (± kWh/± kVarh), supporting maximum/minimum value recording.

Fault record: Up to 8 sets of fault waveforms (including analog/switch values), event logs store the last 8 faults, with a timestamp accuracy of 1ms.

2. Status monitoring

Circuit breaker management: supports three wear calculation methods: ∑ I ^ x, ∑ I ² t, and two-point method, and can set wear limit alarms.

Loop monitoring: Trip loop monitoring (ANSI 74TC), which monitors the status of the trip coil through 1-2 binary inputs.

Motor statistics: Record key data such as startup frequency, startup time, running time, and shutdown time.

Supporting tools and communication

1. Core supporting tools

Tool Name Core Function Key Features

DIGSI 4 project configuration, parameter settings, CFC programming support one-time/two-way value switching, routing matrix configuration, 30 day trial version

SIGRA 4 fault waveform analysis supports 6 chart types, multiple waveform synchronization, and COMTRADE format import

The IEC 61850 System Configurator supports cross vendor configuration of IEC 61850 devices, supporting SCL file import and export, and is compatible with Ed1/2.0/2.1 versions

2. Communication capability

Supporting protocols: IEC 61850 (Ethernet) IEC 60870-5-103、PROFIBUS DP、MODBUS RTU、DNP 3.0/DNP3 TCP、PROFINET IO。

Communication topology: RS485 bus (up to 31 devices), fiber ring network (anti-interference), Ethernet redundancy (RSTP/PRP/HSR).

Remote access: Supports modem/Ethernet remote access, web server monitoring (some models).

Installation and Technical Parameters

1. Installation requirements

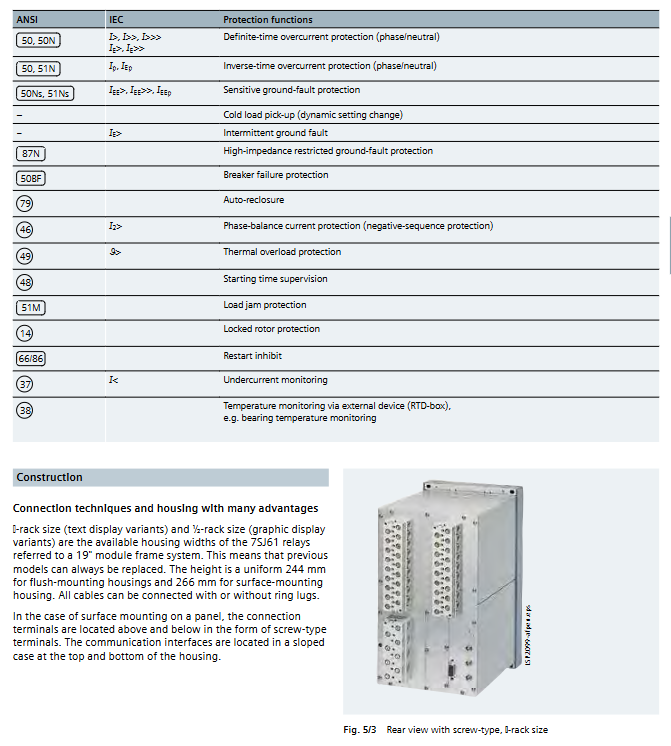

Installation method: 19 inch rail installation, shell width 1/3~1/2 rack (244mm standard height).

Wiring specifications: The current terminal supports 2.7-4mm ² wire, the voltage terminal supports 0.5-2.5mm ² wire, and supports ring terminal/direct connection.

Environmental adaptation: Working temperature -25 ℃~+70 ℃, humidity 5% -95%, no condensation, altitude up to 6000m (with capacity reduction required).

2. Key technical parameters

Core indicators of parameter categories

Current circuit rated current 1A/5A, overload capacity 20A continuous, 500A/1s

Voltage circuit rated voltage 100V~225V, power consumption<0.3VA/phase

Auxiliary voltage DC 24-250V, AC 115-230V, ripple tolerance ≤ 12%

Binary input 8-11 channels, response time ≈ 3.5ms, voltage threshold switchable

Binary output 4-8 channels, switching capacity 30A/0.5s (current on)

Typical application scenarios

Recommended Application Object Model Core Protection Configuration

Radiation type line 7SJ61/62 overcurrent+ground fault+automatic reclosing

Directional overcurrent+fault location+interlocking control for ring network line 7SJ62/64

Transformer 7UT612/613+7SJ80 differential protection+backup overcurrent+high impedance grounding protection

High voltage motor (>1MW) 7UM62/7SJ64 overload+locked rotor+negative sequence+temperature monitoring

Bus protection 7SS52 distributed differential+circuit breaker failure protection

Generator transformer set 7UM62 demagnetization+out of step+reverse power+stator grounding protection

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923