+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

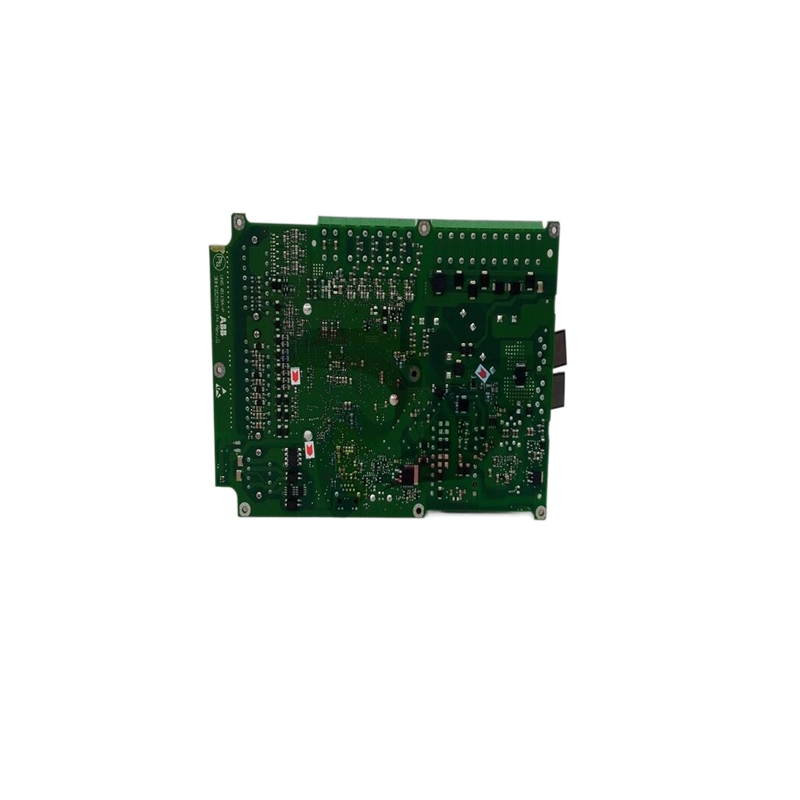

ABB SNAT602TAC DCF1001395P0001 Control Unit

ABB SNAT602TAC DCF1001395P0001 Control Unit

ABB SNAT602TAC DCF1001395P0001 Control Unit

1.1 Data Package

All important documents for the sales order are saved in a folder on a SharePoint site using a custom

shared link. Included in the sales order documents are the drawings, manuals, replacement parts list

and test data needed to support installation and operation of the analyzer(s). This manual refers to

these resources as the “Data Package.”

1.2 Drawings

Since analyzer configuration depends on the application, this manual does not contain generic

engineering drawings and diagrams. Utilize the drawings, diagrams and replacement parts lists

provided in the Data Package for your analyzer to ensure you are using the correct ones for your

system.

1.3 Master controller

The Master Controller can support up to four ovens in any combination of Class B and Class C ovens,

depending on detector configurations. If internal I/O modules are utilized, the maximum number of

ovens per Master Controller is three.

The Master Controller contains a Mounting Plate with a Single Board Computer (SBC) PCB, a Power

Supply, one or more SBC CAN Interface Cards, and optional Wago input/output modules. The front

panel assembly has a touchscreen, liquid crystal display (LCD), keypad, and front panel board.

No Master Controller is required for the Oven with Integrated Controller. The Oven with Integrated

Controller can support up to four ovens in any combination of Class B and Class C Ovens, depending

on detector configurations. The user interface is accessed remotely, as described in Section 3.7.

The PGC5000 Generation 2 Master Controller can also act as a stand-alone RUI. In this configuration,

the Master controller will not be connected to an oven, and it will not contain SBC CAN Interface Cards

or Wago input/output modules. It will be connected to the analyzer network via Ethernet and can

connect to any PGC5000 Generation 2 device that is supported.

1.4 Class B oven

The Class B oven, which comes in liquid and vapor versions, houses an isothermal oven which

contains the analytical columns, detector, detector amplifier, temperature controller, control valves,

and sample valve. The Class B oven has one detector and a maximum of four valves.

1.4.1 Liquid version

The liquid version incorporates a liquid sample valve (LSV) as the input to the analysis. The duration

of an analysis depends on the application and consists of the following:

The liquid sample valve injects a fixed volume of sample into a vaporizing chamber.

“Sweep gas” transports the sample out of the vaporizing chamber.

Carrier transports the vaporized sample into the column.

The column then separates the components and passes them into the detector.

The detector measures the sample across the range of high to low concentration.

The liquid sample valve is externally mounted on the right side of the Oven Compartment and extends

through the isothermal oven, allowing direct injection. It is actuated by a solenoid valve located in the

Oven Electronics Compartment. The liquid sample valve captures a specific volume of liquid sample

below its bubble point, injects it into a temperature controlled (vaporizing) chamber of the LSV, which

then sends the vaporized sample into the oven.

1.4.2 Vapor version

The vapor version has a vapor input to the analysis, so it does not require a liquid sample valve. The

duration of an analysis cycle depends on the applications and consists of the following:

Carrier gas transports the vaporized sample through the columns.

The column then separates the components and passes them into the detector.

The detector measures the sample across the range of high to low concentration.

1.5 Class C oven

The Class C oven contains the same components as the Class B oven, but it has the capability to

handle more oven components. The Class C oven has a maximum of two detectors and a maximum of

six valves.

1.6 Oven with integrated controller

The oven with integrated controller can be either a Class B oven or a Class C oven. The distinguishing

feature is that an oven with integrated controller has the Single Board Computer (SBC) PCB installed

in the oven’s electronics compartment.

1.7 Air purge systems

The analyzer is suitable for a Class 1 Division 2 hazardous location, or an Ex Zone 2 area, without

purge and pressurization protection. Purge and pressurization protection of the electronics enclosure is

required for a Class 1 Division 1 location, or an Ex Zone 1 area. Refer to the analyzer nameplate for

purge and pressurization specifications.

1.8 System variations

This manual supports the basic PGC5000 Generation 2 analyzer. Section 9 presents additional

instruction for the PGC5000TPGC (temperature programmed GC). Section 10 includes information

about using the PGC5000A as a CAC replacement. For PGC5007 (fuel sulfur GC) and PGC5009 (fast

GC) information, see their respective manuals linked in the Additional information section.

2 Installation

WARNING – Bodily injury.

Before beginning installation, repair, or maintenance on the analyzer, contact the local Safety

Department to ensure that all safety guidelines, regulations and procedures are followed. This

includes obtaining the proper work permits.

The user is responsible for being familiar and complying with all safety and health guidelines,

regulations and procedures at the analyzer location. Consult Material Safety Data Sheets for

safety requirements.

When working on the analyzer, there is the possibility of exposure to hydrogen, nitrogen, and

other compressed gases. All appropriate precautions and extreme care should be taken when

working with all compressed gases.

Become familiar with the application specifications before working on the analyzer.

Wear protective clothing and equipment, such as rubber gloves and goggles or safety glasses

with side shields. Avoid contact with a hot surface during maintenance work on the analyzer

oven.

Before opening analyzer enclosure doors, be sure the area is safe from hazardous gases and

will remain so the entire time the analyzer is open.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

51

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923