K-WANG

Honeywell Sensepoint XCD gas detector

Honeywell Sensepoint XCD gas detector

Product overview

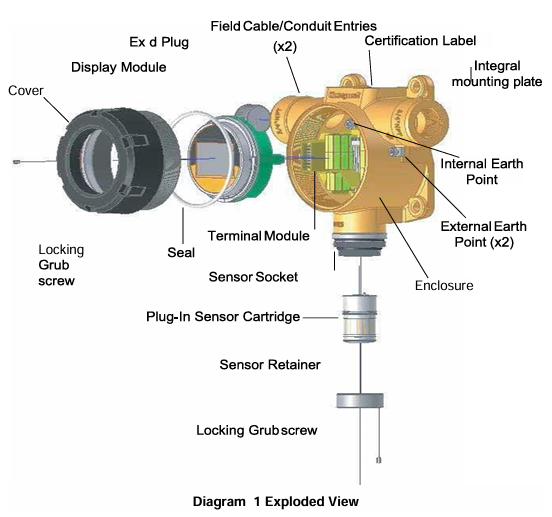

Sensepoint XCD is a fixed gas detector suitable for hazardous areas such as Zone 1/2 and Class I Division 1/2. It can detect flammable gases, toxic gases, and oxygen, and achieve safety monitoring through 4-20mA signal output and programmable relays. It supports Modbus communication (optional), non-invasive operation (magnetic rod activation), and explosion-proof certification. It is widely used in industrial scenarios such as petroleum and chemical industries.

Core functions and technical features

1. Detection capability

Applicable gases:

Flammable gases: methane, propane, etc. (catalytic combustion or infrared technology).

Toxic gases: hydrogen sulfide (H ₂ S), carbon monoxide (CO), hydrogen (H ₂), nitrogen dioxide (NO ₂), etc. (electrochemical technology).

Oxygen (O ₂): Detection concentration range 0-25% Vol (electrochemical technology).

Performance parameters:

Response time (T90): Flammable gas<25 seconds, toxic gas<65 seconds, oxygen<30 seconds.

Accuracy: ± 1.5% LEL (flammable gas), ± 20% or specific value (toxic gas).

2. Output and Communication

Analog output: 4-20mA current signal (configurable as source or drain mode), output<1mA in case of fault, output 2mA or 4mA in suppression mode (17.4mA in oxygen version).

Relays: 3 programmable relays (default A1, A2, fault), supporting normally open/normally closed switching, contact capacity 5A@250VAC .

Optional Modbus RTU: communicates via RS485, supports 9600/19200 baud rates, and can transmit data such as gas concentration and alarm status.

3. Operation and Configuration

User interface: LCD display screen, displaying gas concentration, alarm status, fault codes, etc., operated through magnetic stick activation buttons.

Menu function: Supports calibration, parameter configuration (range, alarm threshold, relay action, etc.), password protection (default 0000).

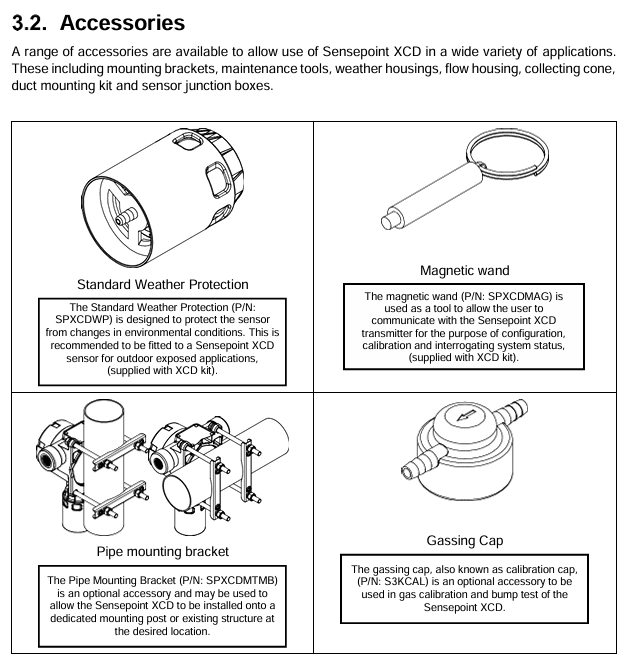

Calibration: A calibration cap (S3KCAL) is required, which supports zero and range calibration. It is recommended to perform it every 6 months.

Installation and wiring

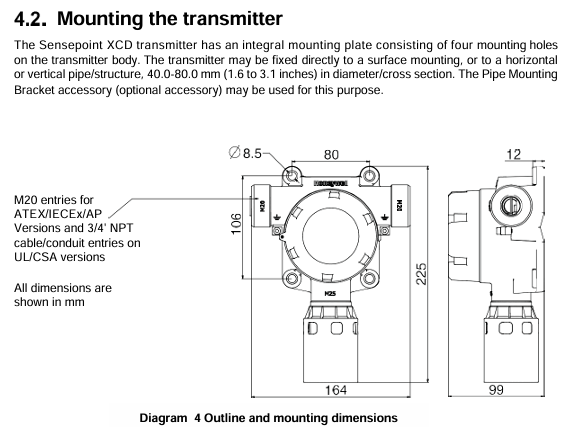

1. Installation requirements

Environmental conditions: working temperature -40 ° C to+75 ° C, humidity 10-99% RH (non condensing), protection level IP66.

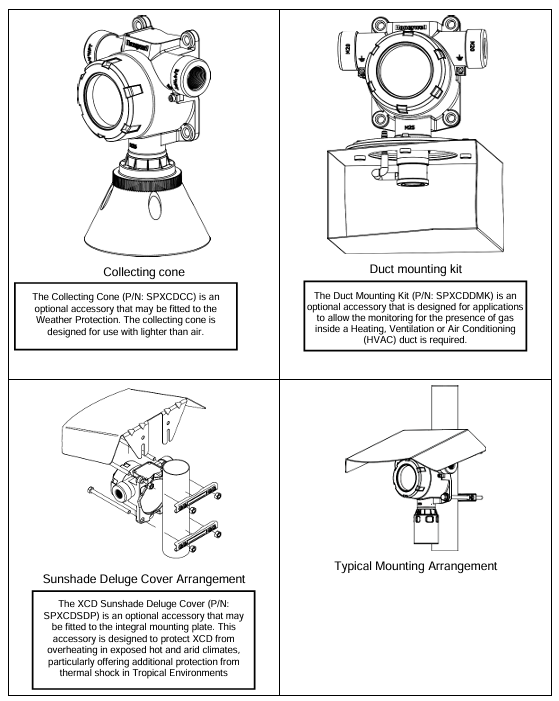

Installation position: Select according to the gas characteristics (such as lighter than air gas requiring a collection cone), and the sensor sintering surface should face downwards to ensure IPX6 protection.

Explosion proof requirements: Cable entrances must be equipped with sealed joints, with a distance of ≤ 18 inches (45cm) from the detector, and grounding must be connected at a single point to avoid loops.

2. Wiring specifications

Power supply: 12-32VDC (UL version) or 16-32VDC (ATEX/IECEx version), power consumption ≤ 5.5W.

Cable selection: It is recommended to use shielded twisted pair cables with a cross-sectional area of 0.5-2.5mm ² (20-13 AWG) and a maximum Modbus transmission distance of 1000 meters.

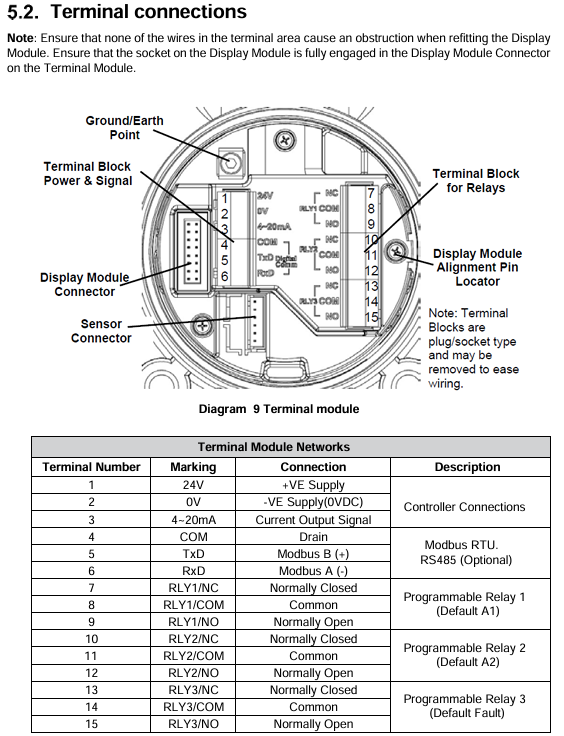

Terminal definition: including power supply, 4-20mA signal, relay, Modbus (optional) interface, specific wiring needs to refer to the terminal table.

Calibration and maintenance

1. Calibration process

Zero point calibration: performed in clean air or using zero gas (such as compressed air).

Range calibration: Introduce 50% of the full range standard gas and confirm the calibration value after stabilization.

Special requirement: The hydrogen sulfide sensor needs to be zeroed with compressed air to avoid the influence of humidity; Infrared sensors need to complete both zero and range calibration simultaneously.

2. Daily maintenance

Sensor replacement: Power off operation is required, and recalibration is needed after replacement. The lifespan of the sensor is usually 2-5 years (depending on the type).

Troubleshooting: By using fault codes (such as F02 indicating sensor failure and F03 indicating zero drift), common problems include wiring errors, power supply failures, sensor aging, etc.

Regular inspection: It is recommended to conduct a bump test every 6 months to ensure that the sensor responds properly

ATEX

ATEX/UKEX:

Certification numbers: UL 21 ATEX 2619X (transmitter), UL 21 ATEX 2620X (sensor head)

Protection level: II 2 GD Ex db IIC T6 Gb (-40 ° C to+65 ° C), Ex tb IIIC T85 ° C Db (-40 ° C to+65 ° C)

Additional requirement: Ensure static grounding to avoid sparks generated by friction.

IECEx:

Certification number: IECEx UL 21.0105X (transmitter), IECEx UL 21.0106X (sensor head)

Protection level: Ex db IIC T6 Gb (-40 ° C to+65 ° C), Ex tb IIIC T85 ° C Db (-40 ° C to+65 ° C).

UL/cUL:

Certification Number: E480011

Applicable area: Class I, Division 1/2(Groups B、C、D)、Class II, Division 1/2(Groups E、F、G)

Temperature range: -40 ° C to+65 ° C.

Performance and Security Certification

European standards:

EN 60079-29-1 (Flammable Gas Performance), EN 45544 (Toxic Gases), EN 50104 (Oxygen).

Other certifications:

Classification society certification (DNV, ABS, CCS, etc.), CE mark (compliant with EN 50270 electromagnetic compatibility standard).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923