K-WANG

ABB 3BSE018138R1 TP858 Baseplate for DDCS InterfaceModule

ABB 3BSE018138R1 TP858 Baseplate for DDCS InterfaceModule

Product Overview

The ABB TP858 base, as a module terminal unit specially designed for distributed digital control system (DDCS) interface modules, plays a key role in industrial automation control systems. Its design aims to provide a stable installation foundation and reliable connection support for specific interface modules, ensuring the stable operation of the entire system communication and control. This base is mainly compatible with DDCS interface modules such as CI858K01 and CI872K01, and is an important component of ABB's construction of efficient and stable industrial control systems.

Basic information

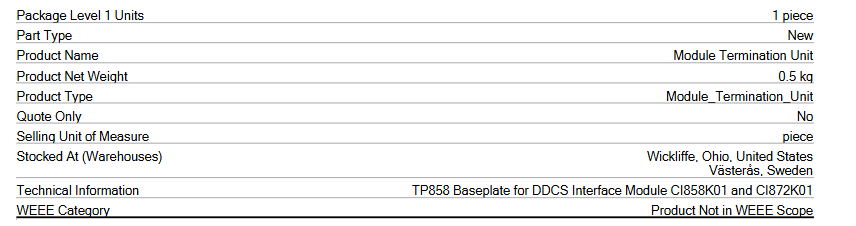

Product identification: The product number is 3BSE018138R1, the model is TP858, the product name is "Module Termination Unit", and the catalog description is "TP858 Baseplate for DDCS Interface Module" (used as the base for DDCS interface modules).

Product attribute: Belonging to the ABB Advant product series, it is a brand new component (Part Type: New), non customized product (Made To Order: No), and does not involve exclusive quotation (Quote Only: No).

Specification and weight

The Gross Weight and Product Net Weight are both 0.5 kg.

The frame size is' Undefined '.

Customs code: 8536909500.

Environmental classification: The WEEE category is "Product Not in WEEE Scope".

Adaptation module: The technical information mentions that it is applicable to DDCS interface modules CI858K01 and CI872K01.

Core functions

Installation support: Provide a stable and safe installation environment for the DDCS interface module, ensuring that the module's performance is not affected by factors such as vibration and displacement during operation. Through a standard installation structure, the interface module can be easily fixed in the designated position of the control cabinet or equipment, ensuring the stable operation of the module in complex industrial environments.

Connection communication: The base is equipped with necessary connection interfaces, responsible for signal transmission and communication between the interface module and other devices. Whether it is data exchange with field devices such as sensors and actuators, or instruction transmission with the upper control system, the TP858 base can provide a reliable physical connection path to ensure stable and accurate signal transmission.

System integration: As a key foundational component of system integration, the TP858 base can organically integrate multiple interface modules into a unified control system. It builds a bridge for collaborative work between different functional modules, helps to construct a complete and efficient industrial automation control network, and improves the operational efficiency and reliability of the entire system.

Precautions

Installation environment: It should be installed in a dry, well ventilated, and non violent vibration environment, avoiding installation in places with high temperature, high humidity, or corrosive gases to prevent damage to the base and modules and affect system performance. It is recommended to control the ambient temperature between 0-50 ℃ and the relative humidity not exceeding 90% (without condensation).

Installation operation: During the installation process, it is necessary to strictly follow the operation manual. Before installation, it is necessary to ensure that all equipment is powered off to avoid safety accidents such as short circuits caused by live operation. During installation, it is necessary to ensure that the base is tightly and stably connected to the interface module, and that all interfaces are correctly connected to prevent signal transmission abnormalities caused by loose connections.

Maintenance: Regularly inspect the base and connected modules for looseness, damage, and other issues. If any problems are found, they should be dealt with promptly, such as tightening loose parts, replacing damaged bases or modules. At the same time, it is necessary to keep the surface of the equipment clean and avoid dust accumulation that may affect heat dissipation and electrical performance.

Application scenarios

In the field of industrial automation, it is widely used in automation control systems in industries such as manufacturing, energy, transportation, and construction. For example, in the automated production line of an automobile manufacturing factory, the TP858 base is equipped with relevant interface modules, which can be used to connect various sensors (such as position sensors, pressure sensors) and actuators (such as motors, cylinders), achieve precise control and data acquisition of production line equipment, and ensure efficient and stable operation of the production line.

Process control system: used in petrochemical, metallurgical, papermaking and other process industries to collect process data (such as temperature, pressure, flow rate, etc.) and control actuators (such as regulating valves, pumps, etc.). Through the collaborative work of TP858 base and interface module, real-time monitoring and precise control of the production process are achieved, ensuring the safety and stability of the production process, and improving product quality and production efficiency.

Energy industry: plays an important role in energy production and distribution systems such as electricity and water conservancy. For example, in power plants, it can be used to connect power monitoring equipment and control systems, achieve real-time monitoring and control of the operating status of power generation equipment, and ensure stable and reliable power supply; In hydraulic engineering, it can be used to control equipment such as water gates and pumps, achieving rational allocation and management of water resources.

Infrastructure field: In the construction of infrastructure such as water supply and drainage, sewage treatment, etc., the TP858 base with interface modules can be used to control related equipment, such as the start and stop of water pumps, the opening and closing of valves, etc., to achieve automated management of infrastructure operation, improve operational efficiency, and reduce maintenance costs.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923