K-WANG

WESTINGHOUSE Three Phase Induction Motors

Installation methods include horizontal foot mounting (HFM), vertical flange mounting (VFM), etc., supporting coupling, belt, chain/gear transmission

Environmental adaptation working temperature: -20~+40 ℃; Storage temperature: -20~+70 ℃; Humidity ≤ 95% RH (fully enclosed), ≤ 80% RH (semi enclosed); Altitude ≤ 1000m

Key electrical parameters insulation resistance: random winding ≥ 5M Ω, formed winding ≥ 100M Ω (calibrated at 40 ℃); Voltage fluctuation is allowed within ± 10%; Frequency fluctuation allowed ± 5%

Protection configuration: winding overheating protection (F-level insulation alarm 140 ℃/trip 155 ℃), bearing high temperature protection (sliding bearing 90 ℃ alarm/95 ℃ trip), overload protection

WESTINGHOUSE Three Phase Induction Motors

Product Overview and Core Parameters

Category specific specifications

Product positioning: Large cast iron frame three-phase induction motor, IEC 280 (NEMA 444) and above specifications

Installation methods include horizontal foot mounting (HFM), vertical flange mounting (VFM), etc., supporting coupling, belt, chain/gear transmission

Environmental adaptation working temperature: -20~+40 ℃; Storage temperature: -20~+70 ℃; Humidity ≤ 95% RH (fully enclosed), ≤ 80% RH (semi enclosed); Altitude ≤ 1000m

Key electrical parameters insulation resistance: random winding ≥ 5M Ω, formed winding ≥ 100M Ω (calibrated at 40 ℃); Voltage fluctuation is allowed within ± 10%; Frequency fluctuation allowed ± 5%

Protection configuration: winding overheating protection (F-level insulation alarm 140 ℃/trip 155 ℃), bearing high temperature protection (sliding bearing 90 ℃ alarm/95 ℃ trip), overload protection

Key process specifications

(1) Reception and Inspection

Appearance inspection: No collision or damage, take photos to record transportation damage and synchronize with the carrier and manufacturer.

Parameter verification: The rated power, voltage, and frequency on the nameplate are consistent with the order, and the attachments (instruction manual, accessories) are complete.

Key verification: The directional arrow markings are clear, and the parameters of auxiliary equipment such as heaters and temperature detectors are compliant.

(2) Storage Management

Storage environment: Clean, dry, well ventilated, temperature between 10-50 ℃, away from boilers/cold storage, avoid vibration (≤ 2.5mm/s), and place the motor on a tray to prevent moisture.

Moisture prevention measures: Use space heaters (according to nameplate voltage) or built-in incandescent lamps to maintain motor temperature 3 ℃ above dew point; Rotate the motor shaft several times a month to avoid bearing corrosion.

Regular testing: Conduct insulation resistance testing and temperature detector resistance calibration every 3 months.

Long term storage (≥ 6 months): Supplement lubrication for bearings, drain water cooling pipelines, remove couplings, and lift electric brushes for protection.

(3) Installation specifications

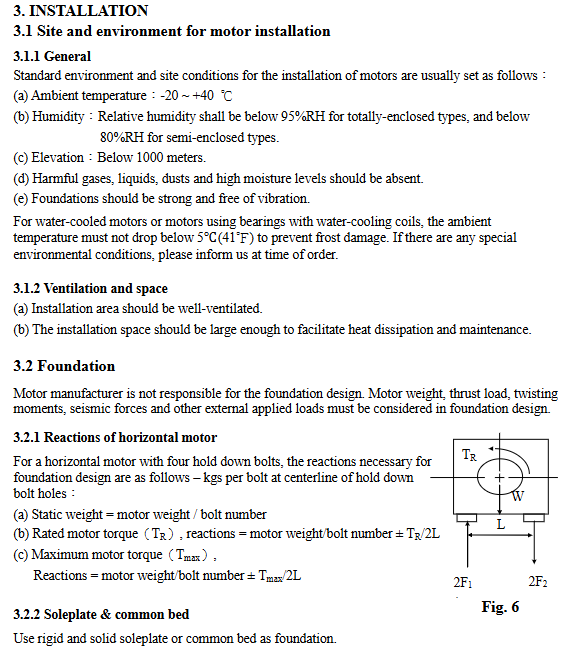

Basic requirements: A rigid base plate/common base should be used, and the foundation should bear the weight and thrust load of the motor, with a horizontal error of ≤ 0.04mm.

Transmission installation:

Couplings: Alignment error (rigid couplings ≤ 0.04mm/flexible couplings ≤ 0.05mm at speeds<2500rpm), end clearance ≤ 2.4mm.

Belt drive: Belt speed ≤ 35m/s, pulley diameter ratio (flat belt ≤ 5:1/V belt ≤ 8:1), pulley installed near the motor body.

Electrical wiring: compliant grounding, cable cross-section matching current, correct starting method and protector parameters, phase sequence verification to ensure correct direction of rotation.

(4) Run operation

Pre startup inspection:

Electrical: The wiring is correct, the insulation resistance meets the standard, and the protector is ready.

Mechanical: Bearing oil level (center of oil gauge), smooth rotation of oil ring, and no foreign object interference.

Auxiliary: The inlet water temperature of the water-cooled motor is 5-30 ℃, and the forced ventilation fan is started 15 minutes in advance.

Start limit: Up to 2 starts in cold state, only 1 start in hot state; Startup failure requires cooling for 30-60 minutes before attempting again. If the rotor does not rotate for 1-2 seconds, immediately stop the machine for troubleshooting.

Operation monitoring: As the load gradually increases, real-time monitoring of three-phase current (imbalance ≤± 5%), bearing temperature (≤ 95 ℃), and vibration (≤ 3.8mm/s) is carried out.

Maintenance and upkeep core

(1) Maintenance cycle and project

Key requirements for maintenance cycle core projects

Daily oil level check, oil ring rotation, leakage monitoring. The oil level is at the center of the oil gauge and there is no dripping or leakage

Every month, the bolts are tightened, the coupling is in good condition, and the filter is clean. All bolts are not loose, and the filter is not clogged

Quarterly insulation resistance testing and bearing grease replacement. If the insulation resistance is ≥ 5M Ω, grease should be added according to the bearing model (such as 6310, add 40g)

Every six months, the winding/exterior is cleaned and the oil is replaced. The winding is free of dust and oil stains, and the sliding bearings are replaced with rust proof turbine oil

Annual vibration testing, coupling re alignment vibration ≤ 3.8mm/s, alignment error ≤ 0.04mm

Open the cover for inspection every 2 years (without disassembling the rotor) to ensure that the coil does not change color and the bearings are not corroded

Disassemble and inspect the rotor bars and stator windings every 4 years for comprehensive testing

(2) Core component maintenance

Winding maintenance:

Cleaning: Compressed air (≤ 4kg/cm ²) or vacuum cleaning, wipe oil stains with safe solvents (chlorine containing solvents are prohibited).

Moisture proof: Use the space heater when idle to avoid coil condensation.

Testing: Measure with a 500VDC/1000VDC megohmmeter. If the resistance does not meet the standard, it needs to be dried.

Bearing maintenance:

Lubricating medium: default ExxonMobil Polyrex EM grease, mixing different types of grease is prohibited.

Lubricating specification: According to the bearing model (such as 6310, lubricate 40g every 2000 hours), lubricate during operation and then empty load for 10-30 minutes to remove the old grease.

Sliding bearings: Keep the oil level at the center of the oil gauge, change the oil every 6 months, and select the viscosity of the oil according to the number of poles (ISO VG32 for 2-pole).

Maintenance of transmission system:

Couplings: Regularly check the tightness of bolts, and realign if there is any abnormal vibration during operation.

Belt drive: Maintain uniform tension, with pulley diameter ≥ minimum recommended value (e.g. 45kW 4P motor V pulley ≥ 265mm).

Troubleshooting and Handling

Common causes and solutions for fault phenomena

Unable to start (no movement), power outage, broken wiring, missing fuses. Check power supply, repair wiring, install matching fuses

Start tripping/fuse melting winding short circuit, single-phase operation, overload detection winding insulation, troubleshooting wiring, reducing load

Overheating and overload during operation, ventilation blockage, excessive ambient temperature to reduce load, cleaning ventilation ducts, and improving environmental heat dissipation

Bearing high temperature/abnormal noise, insufficient lubrication, improper installation, bearing wear, replenishment of lubricating grease/oil change, re alignment, replacement of bearings

Excessive vibration, unbalanced rotor, insufficient foundation stiffness, eccentric rotor dynamic balance correction of coupling, reinforcement of foundation, adjustment of coupling

Recycling and Compliance

Material classification: Steel frame, copper winding, cast iron components are classified and recycled, and insulation materials are disposed of according to local regulations.

Hazardous waste: Lubricating oil is classified as hazardous waste and requires compliant recycling. Random discharge is prohibited.

Permanent magnet motor: Before recycling, it needs to be heated to 300 ℃ for demagnetization to avoid magnetic field interference with electronic devices.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923