K-WANG

SHINKAWA VM-5 Series Monitor

SHINKAWA VM-5 Series Monitor

The VM-5 series monitor is produced by SHINKAWA Sensor Technology, Inc. and complies with API standard 670. It is suitable for monitoring various types of rotating machinery and offers three device forms: 8-slot, 10 slot rack mounted, and single machine with built-in power supply. It covers 18 monitoring units such as vibration, displacement, eccentricity, temperature difference expansion, speed, temperature, etc., and is equipped with dedicated sensors and relay, communication and other module units. It has flexible configuration, data communication, fault alarm, power-off backup and other functions. It has passed multiple international standard certifications and can meet the diverse monitoring needs from small rotating machinery to large turbine TSI systems.

Product Overview

Manufacturer: SHINKAWA Sensor Technology, Inc

Core positioning: A monitoring system designed specifically for rotating machinery, compliant with API standard 670, suitable for all scenario requirements from small and medium-sized equipment to large turbine TSI (Turbine Monitoring Instrument)

Certification qualifications: Passed CE certification, multiple classification society standards (Japan NK, South Korea KR, UK LR)

Core advantages: flexible configuration, convenient operation (full front-end operation without downtime), comprehensive functions, high reliability

Equipment form and installation

Equipment type, model, core parameters, installation characteristics

Rack mounted VM-5H3 with 8 slots, capable of accommodating up to 8 monitoring units and 1 communication/phase marking unit. The front-end is equipped with monitoring units, while the back-end is equipped with modules/power supply units

Rack mounted (dual power) VM-5W1 10 slot, capable of accommodating up to 10 monitoring units and 1 communication/phase marking unit, supporting 2 VM-5Z power units with redundant dual power design, seamless switching in case of failure

Single machine VM-5G built-in power supply, pre installed relay module does not require additional module installation, plug and play

Core constituent units

(1) Monitoring units (18 types, classified by function)

Functional category, model, core use, key parameters

Vibration Monitoring VM-5K (Dual Vibration) 2-channel Shaft Vibration Monitoring Monitoring Range 0-500 μ m pk pk, Accuracy ± 0.5% F.S. (25 ℃)

Vibration monitoring VM-55 (vibration) simultaneously monitors relative/absolute vibration or relative/seismic vibration within the monitoring range of 0-800 μ m pk pk, with an accuracy of ± 3.0% F.S. (25 ℃)

Vibration monitoring VM-5U (dual seismic) 2-channel velocity sensor signal input monitoring range 0-500 μ m pk pk or 0-50mm/s pk, accuracy ± 0.5% F.S

Vibration monitoring VM-5B (dual acceleration) 2-channel acceleration sensor signal input monitoring range 0-200m/s ² pk, accuracy ± 0.5% F.S

Vibration monitoring VM-5M (dual path) simultaneously monitors speed/acceleration, displacement/velocity monitoring range including 0-200m/s ², 0-500 μ m and other multiple specifications

Displacement/eccentricity VM-5C (eccentricity) monitoring of shaft deflection during turbine rotor start-up/turning, monitoring range 0-1000 μ m pk pk, accuracy ± 1.0% F.S. (25 ℃)

Displacement/eccentricity VM-5T (dual thrust) monitoring rotating mechanical shaft position monitoring range -2.0~+2.0mm, accuracy ± 0.5% F.S. (25 ℃)

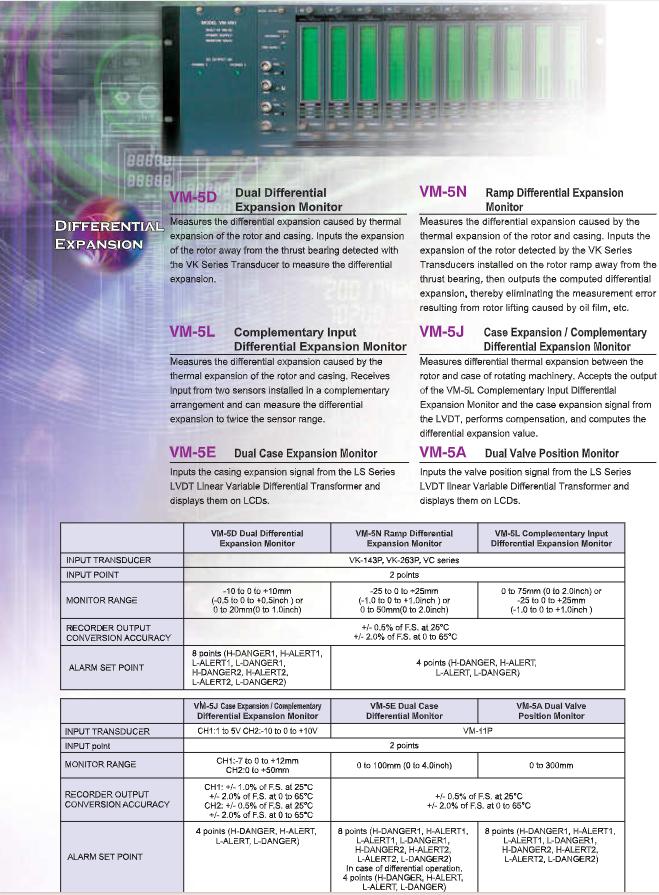

Temperature difference expansion VM-5D/5N/5L/5J/5E measures the thermal expansion difference between the rotor and the casing. Some models support complementary input and the range is expanded by 2 times

Speed monitoring VM-5S (dual speed) monitors rotor speed and zero speed with a maximum range of 99999 rpm and an accuracy of ± 0.5% F.S. (25 ℃)

Speed monitoring VM-5Q (reverse rotation) detects peak reverse speed with a maximum range of 20000rpm

Speed monitoring VM-5R (speed) monitors speed and acceleration, supports independent threshold setting acceleration range -9999~+9999rpm/min

Temperature monitoring VM-5F (dual temperature) monitors the temperature of rotating machinery (not applicable to VM-5G) with a range of 0-1000 ℃ and an accuracy of ± 1.0 ℃ when the temperature is ≤ 500 ℃

Other monitoring VM-51 (rod drop) measures the clearance between the piston rod and the sensor, converts the rider ring wear range from 0-10.0mm, and has an accuracy of ± 2.0% F.S. (0-65 ℃)

Other monitoring VM-52 (bottom hold) measures the clearance between the piston and sensor to obtain the wear range of 0-4.5mm, with an accuracy of ± 1.0% F.S. (25 ℃)

(2) Module unit

Module type, model, core function, key parameters

The relay module VM-5Y series outputs alarm, OK and other contact signals, supports sequence control of 2-6 relay points, and has a contact capacity of 250VAC/5A

Interface module VM-5X series allocates recorder output signals, simplifies wiring input 1-5VDC/4-20mA, outputs up to 8 points

Communication module VM-53 (dual communication) dual serial port, Modbus protocol, supports multi rack Daisy Chain connection baud rate 1200-38400bps (RS-485)

Phase marking module VM-5P3 processes phase marking signals, detects power supply faults with 2-channel input and output impedance of 500 Ω

The VM-5Z series power module provides DC power output of 24VDC/4mA or -24VDC/40mA for units inside the rack, with fault alarm indication

When the power backup module VM-5Z0 experiences an instantaneous power outage, it will backup for 0.2 seconds under the maximum load of the backup power supply, occupying space for 2 monitoring units

(3) Supporting sensors

Types: FK/VK series vibration sensors, CV/CA series speed/acceleration sensors, RD series speed sensors, LS series LVDT linear sensors, etc

Advantages: High reliability, strong adaptability to specifications, ensuring monitoring stability

Key functions and technical parameters

(1) Core functions

Multivariate monitoring: covering full dimensional parameters such as vibration, displacement, eccentricity, temperature expansion, rotational speed, temperature, and rod drop

Data communication: Output measurement data to PC or InfiSYS RV-200 diagnostic system through VM-5P/VM-53 unit, supporting PC end alarm settings

Alarm mechanism: multi-level alarm (DANGER1/2, ALERT1/2), LED visual indication, relay contact output

Reliability design: VM-5W1 dual power redundancy, VM-5Z0 0.2 second power-off backup to ensure continuous operation

Flexible Expansion: Supports optional feature upgrades such as RMS rectification, insulation output card, and tropical specifications

(2) General Technical Parameters

Parameter category specific specifications

Working temperature 0-65 ℃ (monitoring unit/module), some power modules 0-50 ℃

Recorder output standard: 1-5VDC (impedance 250 Ω), 4-20mA (maximum load 500 Ω); Optional 0- ± 10VDC, etc

Monitor the output of the buffer amplifier, with an impedance of approximately 100 Ω

Accuracy range ± 0.5%~± 3.0% F.S. (varies depending on unit model and temperature)

Storage temperature -30~+85 ℃ (most units)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB AX411/511010/STD pH/ORP Analyzer Controller

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923